Method for quick and non-destructive determination of content of amylase in corn single grains

A technology of amylose content and grain, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of time-consuming and high cost, and achieve the effect of overcoming time-consuming, fast analysis speed and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Collection of Near Infrared Spectrum of Corn Single Kernel

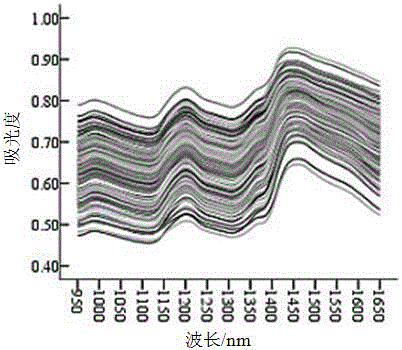

[0023] A total of 196 corn single-grain samples were collected, and all materials were equilibrated at room temperature for 60 days before collecting spectra. The spectrum of the sample was collected using a DA7200 near-infrared spectrometer from Perten Company, with a spectral range of 950–1650 nm and a resolution of 2 nm. The single-grain mirror sample tray is used to load the sample, and the grain should be placed horizontally in the center of the sample tray, with the side without germ facing upward. Each sample was loaded 3 times, each sample was scanned 2 times, and the average spectrum was saved (see figure 1 ).

Embodiment 2

[0024] Example 2 NIRS model of single corn amylose content

[0025] 2.1 Model establishment

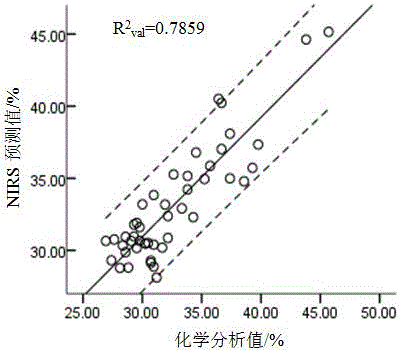

[0026] After extracting the total starch of each sample, use the dual-wavelength iodine colorimetric method to measure the amylose content of each sample. The measurement wavelengths are 620nm and 510nm respectively. The samples are arranged according to the chemical value from small to large, and every 3 samples are taken to form a verification set. For model validation, the remaining samples constitute the calibration set for modeling. The multivariate chemometric analysis software The Unscrambler (version 9.8) was used to perform first-order derivative + standard orthogonal variable transformation (SNV) spectral preprocessing on the sample spectrum collected in Example 1, and a mathematical model was established by PLS and cross-validated. The modeling results show that the correction set determines the coefficient R 2 =0.8970, cross-validation standard deviation RMSECV=1.805.

...

Embodiment 3

[0029] Embodiment 3 Predict the amylose content of the sample to be tested

[0030] Scan an unknown corn single-grain sample, compare the near-infrared spectra of the unknown sample and the calibration sample, and use the model established above to predict the amylose content of the unknown sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com