Backlight module, display panel comprising same and electronic device

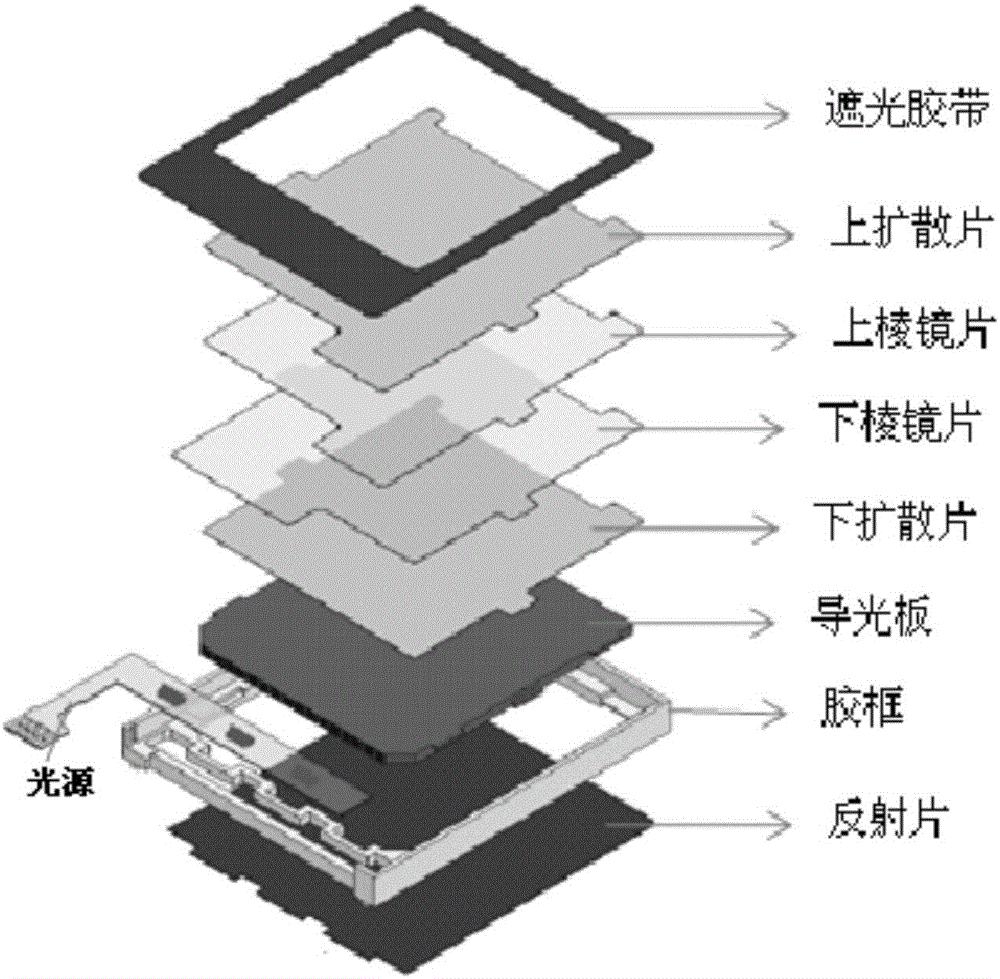

A technology for a backlight module and a light guide plate is applied in the fields of display panels, electronic equipment, and backlight modules, and can solve the problems of cumbersome preparation process, large thickness, and the need for improvement of the backlight module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

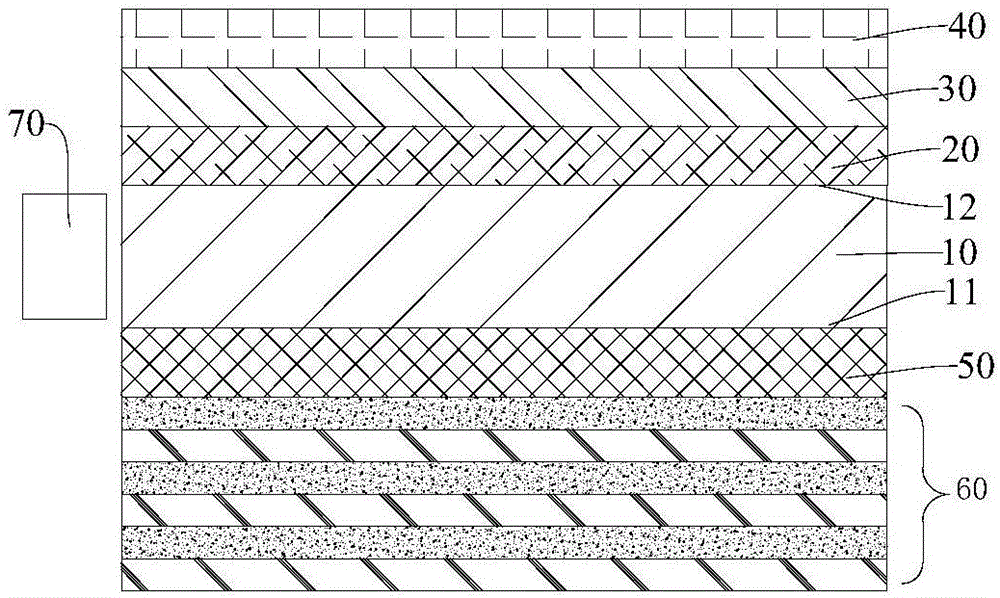

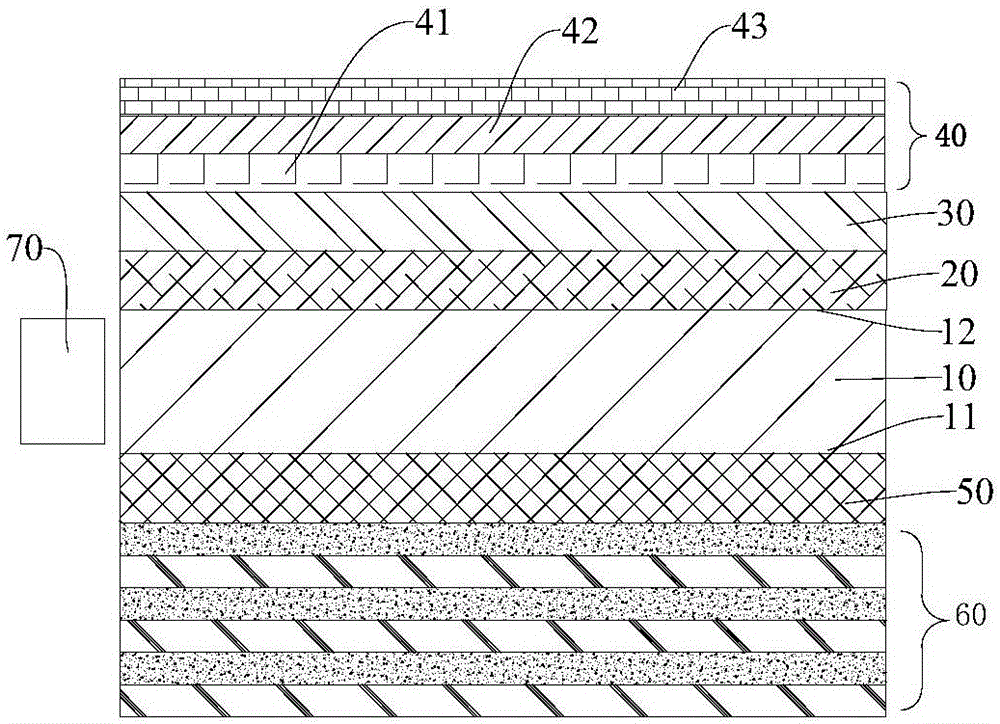

[0052] In this embodiment, a plurality of coating layers are respectively formed on the light-emitting surface and the light-incident surface of the light guide plate (PMMA) by evaporation, coating, etc., to obtain image 3 In the backlight module shown, the refractive index of the light guide plate is 1.49, the refractive index of the first low-refractive coating layer and the second low-refractive coating layer are about 1.38, and the refractive indices of the titanium dioxide layer and the silicon dioxide layer in the Bragg reflective layer are respectively are 2.38 and 1.46, and the quantity and thickness of titanium dioxide layer and silicon dioxide layer are shown in the table below. At the same time, according to the above steps to form a contrast backlight module, the difference is that a single-layer silver coating or aluminum coating is formed on the light-incident surface of the light guide plate instead of a Bragg reflection layer.

[0053]

[0054] Measure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com