Method for reducing fluorescent powder sedimentation rate of surface mount device

A surface mount device and sedimentation rate technology, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of wide color range of products, uneven light spots of finished products, and failure to meet the requirements of testing, so as to optimize LED color Concentration, uniform luminous spot, no effect of aperture hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

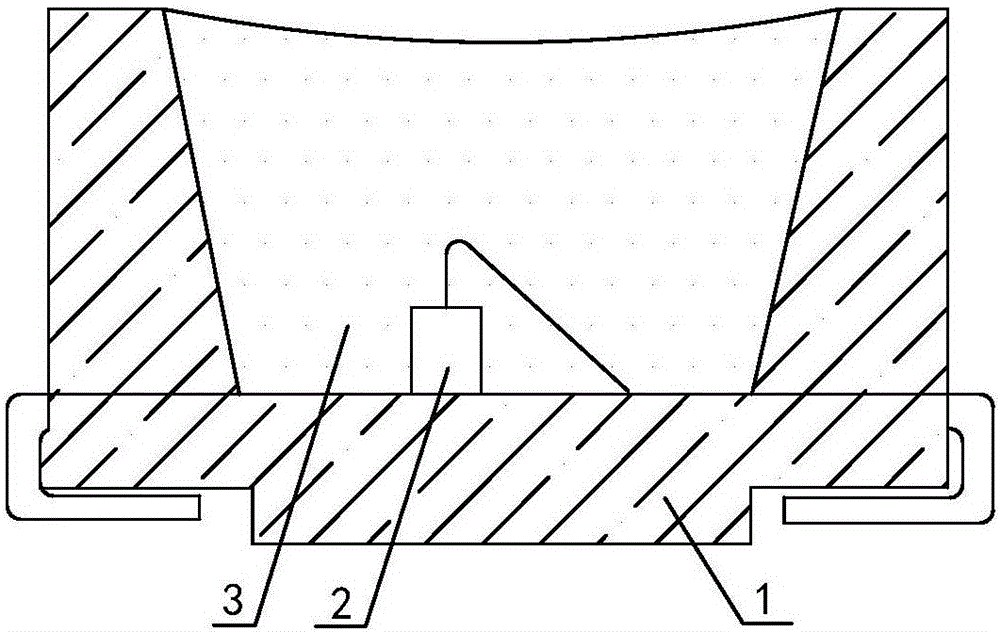

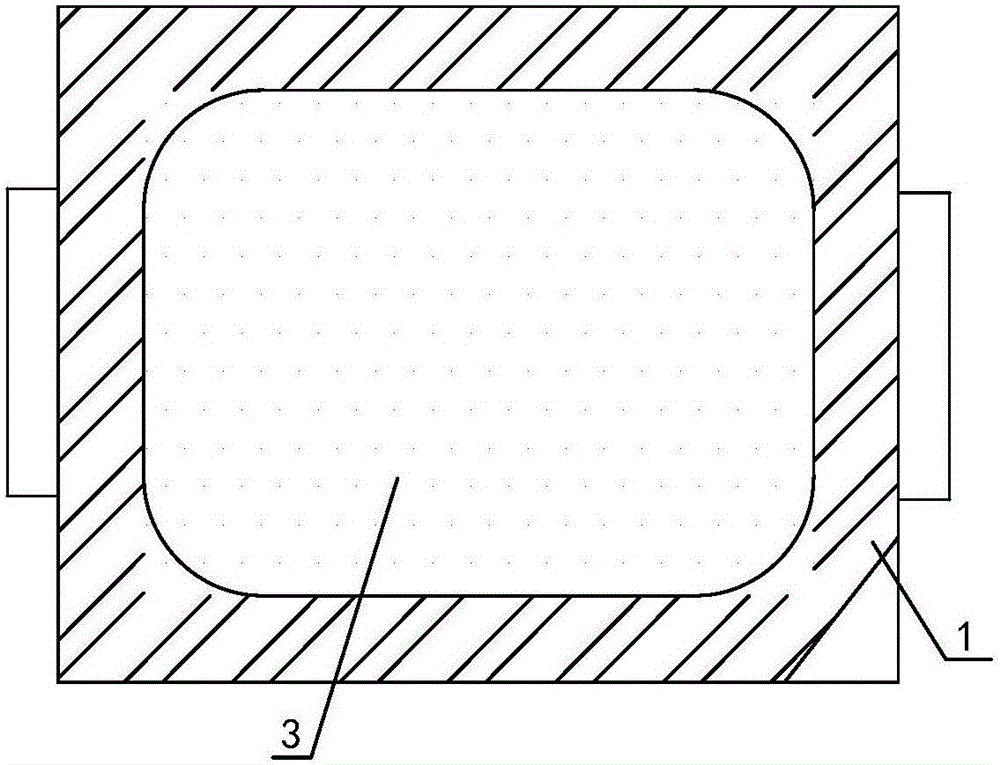

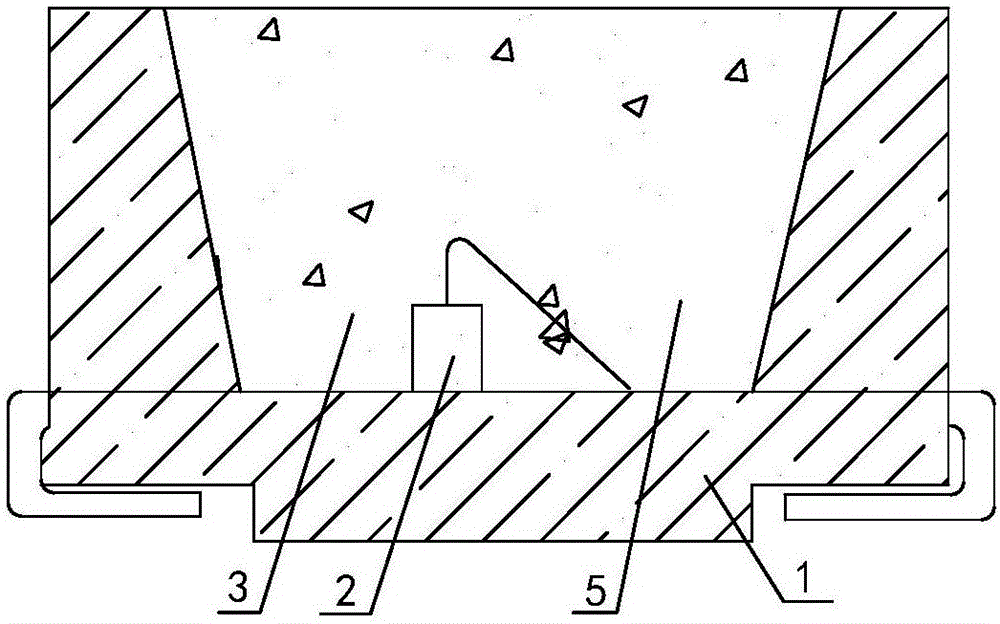

[0030] Such as Figure 1-4 As shown, the method for reducing the sedimentation rate of phosphor powder in the surface mount device described in the embodiment of the present invention mainly consists of the following steps:

[0031] (1) At first, install the light-emitting chip 2 of the built-in chip at the bottom of the SMD support body 1;

[0032] (2) Then, prepare silicone filling glue of model KMT-1212A, colloid of model KMT-1212B, and DM-30 anti-sinking powder. The weight ratio of the three raw materials is 5:0.06:1 in sequence. Mix KMT-1212A silicone filling glue and KMT-1212B colloid and fill it inside the frame to form colloid 5, and there is a descending vertical space with an inverted trapezoidal structure between the top surface of light-emitting chip 2 and colloid 5;

[0033] (3) adding fluorescent powder 3 inside the colloid 5;

[0034] (4) Finally, add the DM-30 anti-sinking powder 4 prepared by step (2) into the colloid 5 obtained in step (3).

Embodiment 2

[0036] Such as Figure 1-4 As shown, the method for reducing the sedimentation rate of phosphor powder in the surface mount device described in the embodiment of the present invention mainly consists of the following steps:

[0037] (1) First, arrange the chip at the bottom of the SMD support body 1 and install the light-emitting chip 2, the chip is detachable and has a chip slot inside the SMD support body 1;

[0038] (2) Then, prepare silicone filling glue of model KMT-1212A, colloid of model KMT-1212B, and DM-30 anti-sinking powder. The weight ratio of the three raw materials is 5:0.06:1 in sequence. The silicone filling glue of KMT-1212A and the colloid of model KMT-1212B are mixed and filled inside the frame to form a colloid, and there is a descending vertical space with an inverted isosceles trapezoidal structure between the top surface of the light-emitting chip and the colloid;

[0039] (3) adding fluorescent powder 3 inside the colloid 5;

[0040] (4) Finally, add ...

Embodiment 3

[0042] The method for reducing the sedimentation rate of phosphor powder in the surface mount device described in the embodiment of the present invention, in addition to the steps adopted in embodiment 1 or embodiment 2, also includes that the colloid 5 and the edge of the top surface of the frame A fixed adhesive layer is arranged between the positions; several protruding pin end pieces are formed on the outside of the SMD support body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com