Rosa roxbunghii health-care beverage and making method thereof

A technology for health-care beverages and prickly pears, which is applied in the directions of pharmaceutical formulas, plant raw materials, and medical preparations containing active ingredients, can solve the problems of easy browning, poor palatability of fresh fruit, sour taste, etc., and achieves good product quality and palatability. Good, no browning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

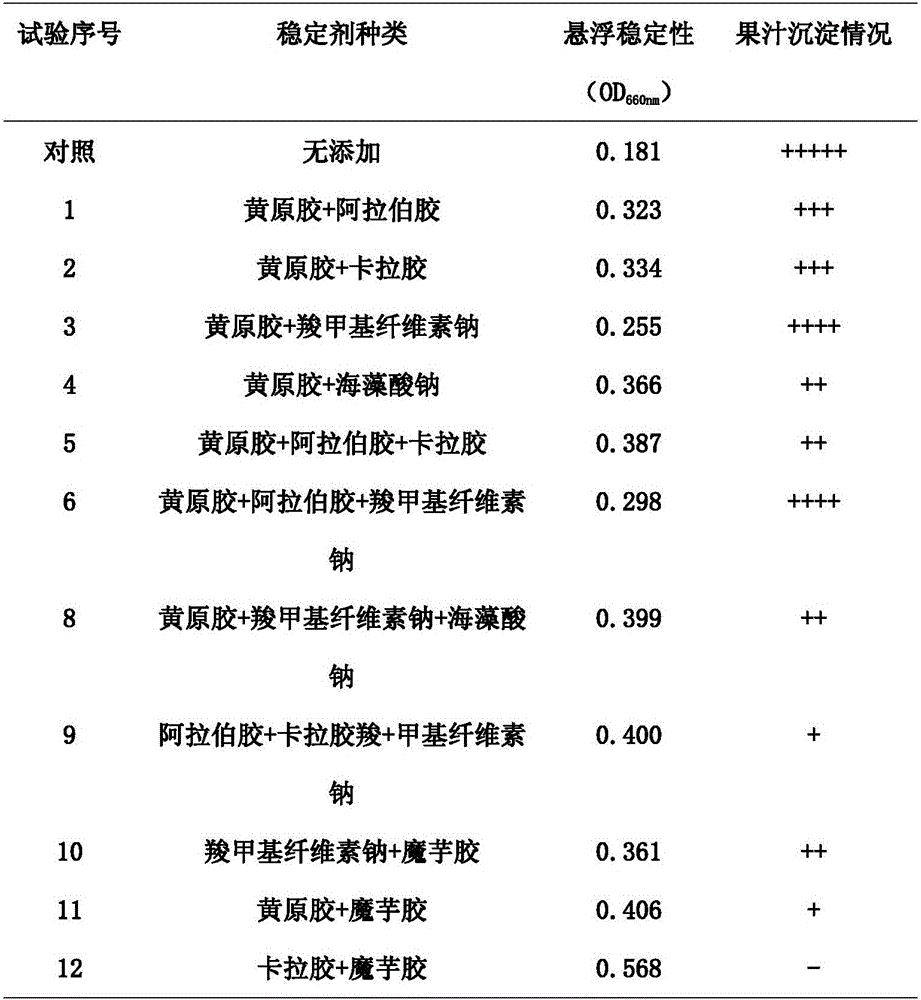

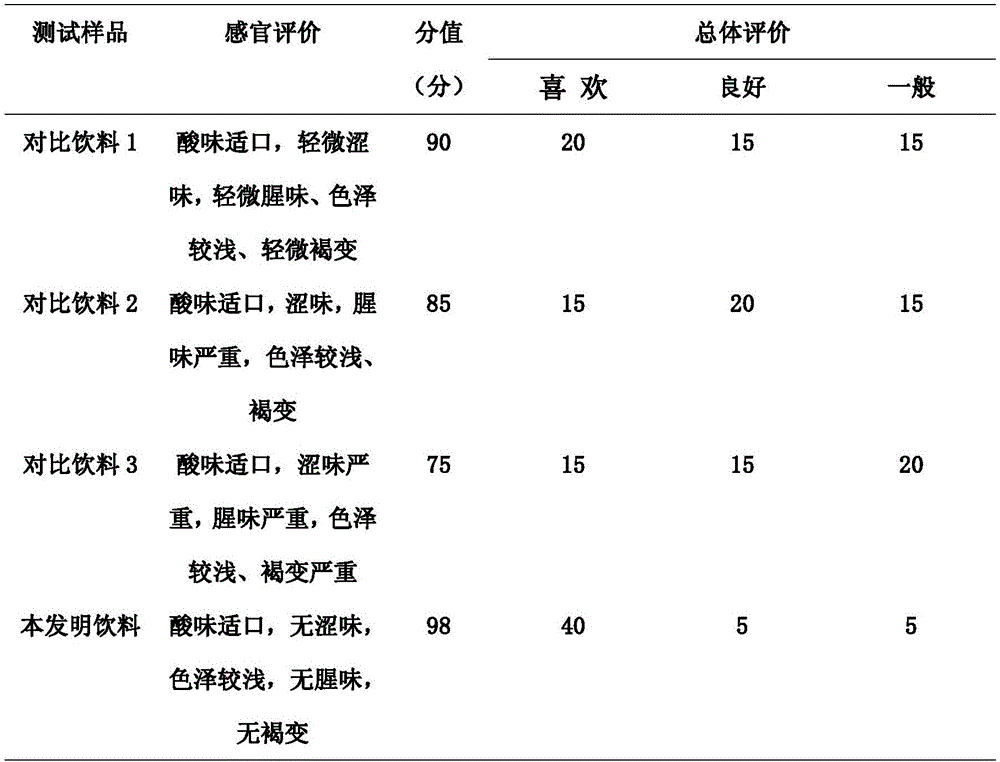

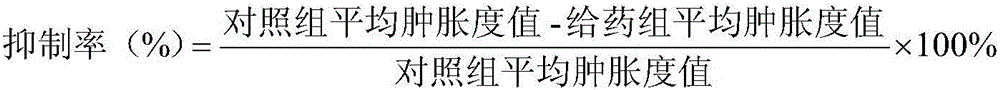

Method used

Image

Examples

Embodiment 1

[0057] Raw materials: prickly pear juice 130kg, houttuynia cordata juice 30kg, monk fruit concentrate 20kg, carrageenan 0.03kg, konjac gum 0.03kg, alitame 0.02kg, glycyrrhizin 0.02kg, sucralose 0.02kg and purified water 1000kg.

[0058] Production process of prickly pear juice: take prickly pear fruit, remove the thorns, wash, freeze at -4-0°C for 12 hours, place at room temperature for 35 minutes, crush, filter, and use the filtrate for later use; add 6 times the amount of water to the filter residue, and add the filter residue 0.03% by weight wine active dry yeast, mixed evenly, put into a fermenter, cultured in a constant temperature shaking incubator at 33-37°C, the shaking frequency was 130r / min, fermented for 6 days, filtered, and after removing the filter residue, Mix with the above filtrate, that is.

[0059] The production process of Houttuynia cordata juice: Take Houttuynia cordata and add 10 times the amount of water to soak for 20 minutes, decoct for 2.5 hours, fil...

Embodiment 2

[0068] Raw materials: prickly pear juice 140kg, houttuynia cordata juice 35kg, monk fruit concentrate 25kg, carrageenan 0.04kg, konjac gum 0.04kg, alitame 0.025kg, glycyrrhizin 0.025kg, sucralose 0.025kg and purified water 1050kg.

[0069] Production process of prickly pear juice: take prickly pear fruit, remove the thorns, wash, freeze at -4-0°C for 14 hours, place at room temperature for 40 minutes, crush, filter, and use the filtrate for later use; add 7 times the amount of water to the filter residue, and add the filter residue 0.04% wine active dry yeast by weight, mixed evenly, put into a fermenter, cultured in a constant temperature shaking incubator at 33-37°C, the shaking frequency was 135r / min, fermented for 6 days, filtered, and after removing the filter residue, Mix with the above filtrate, that is.

[0070] Production process of Houttuynia cordata juice: Take Houttuynia cordata and add 12 times the amount of water to soak for 30 minutes, decoct for 3 hours, filter...

Embodiment 3

[0079] Raw materials: prickly pear juice 120kg, houttuynia cordata juice 25kg, monk fruit concentrate 15kg, carrageenan 0.02kg, konjac gum 0.02kg, alitame 0.015kg, glycyrrhizin 0.015kg, sucralose 0.015kg and purified water 950kg.

[0080] The production process of Rosa roxburghii juice: take Rosa roxburghii fruit, remove the thorns, wash, freeze at -4-0°C for 10 hours, place at room temperature for 30 minutes, crush, filter, and reserve the filtrate; add 5-7 times the amount of water to the filter residue, Add wine active dry yeast with 0.02% weight of the filter residue, mix well, put it into a fermenter, put it in a constant temperature shaking incubator at 33-37°C, and cultivate it at a constant temperature of 125r / min, ferment for 5 days, filter, and remove the filter residue After that, mix with the above-mentioned filtrate to obtain.

[0081] Production process of Houttuynia cordata juice: Take Houttuynia cordata and add 8 times the amount of water to soak for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com