Chitosan toothpaste and preparation method thereof

A technology of chitosan and toothpaste, applied in the field of oral cleaning and care products, can solve problems such as sour taste, and achieve the effects of unique flavor, sweet taste and excellent antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

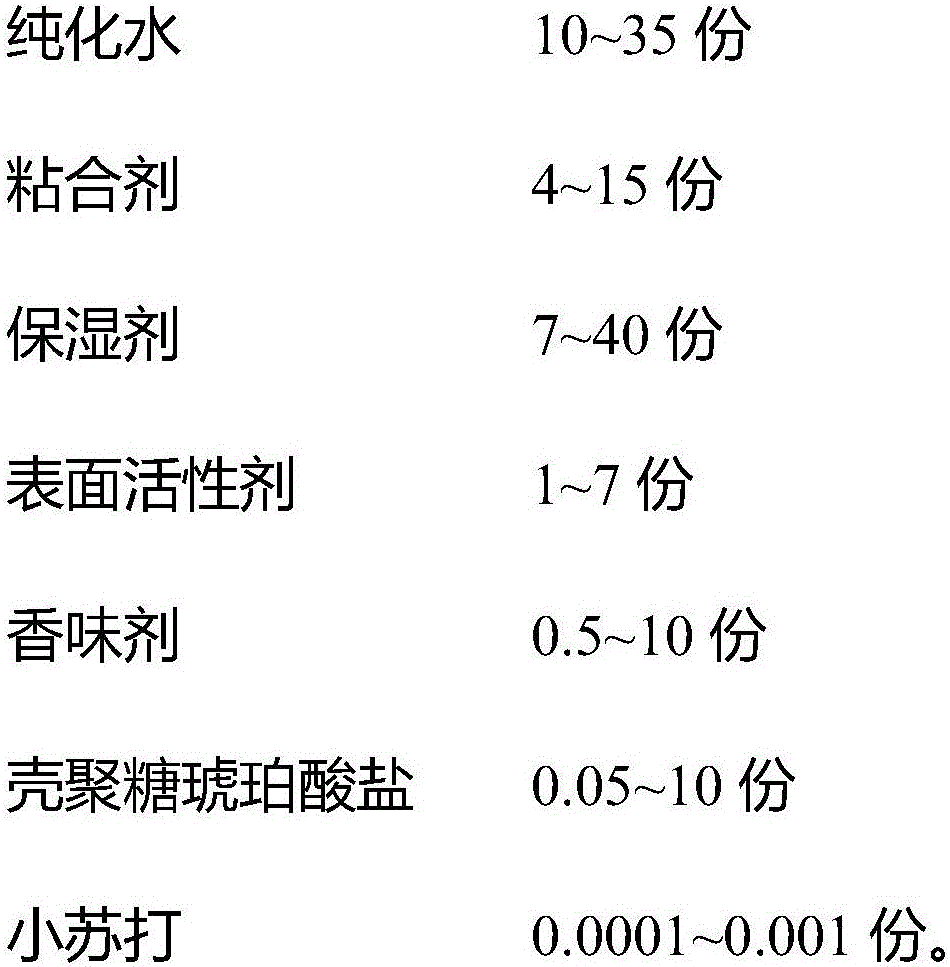

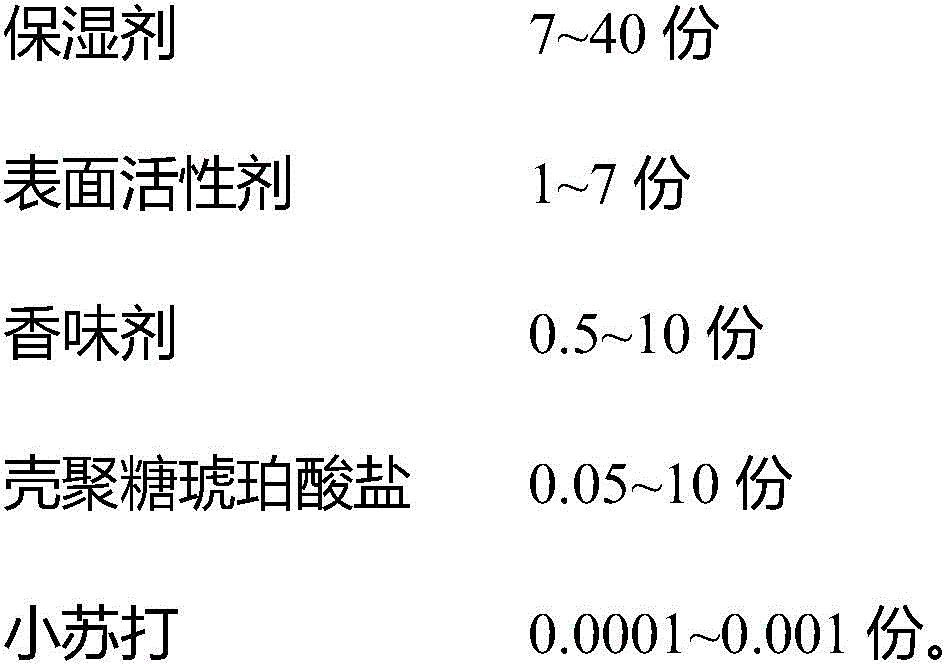

[0028] The preparation method of this chitosan toothpaste, comprises the following steps:

[0029] (1) Dissolve 0.0001 to 0.001 parts of baking soda in 10 to 35 parts of purified water according to the formula ratio, and prepare a baking soda solution with pH=7 to 8 for later use;

[0030] (2) Put 0.05-10 parts of chitosan succinate into the paste-making pot, add 4-15 parts of binder and 7-40 parts of humectant, and stir evenly to form a thick mixture;

[0031] (3) Then add 1 to 7 parts of surfactant, 0.5 to 10 parts of flavoring agent and the baking soda solution obtained in step (1) into the paste making pot in sequence, stir with a scraper, stir for 0.5 to 2 hours, and then take it out of the pot, that is Obtain the chitosan toothpaste finished product.

[0032] In step (2), the binder is one or both of cellulose gum and carrageenan, and the humectant is one or both of sorbitol and glycerin.

[0033] In step (3), the surfactant is sodium lauryl sulfate, and the flavoring ...

Embodiment 1

[0035] (1) Dissolve 0.0001 part of baking soda in 10 parts of purified water according to the formula ratio, and prepare a baking soda solution with pH=7-8 for later use;

[0036] (2) Put 0.05 part of chitosan succinate into the paste-making pot, add 4 parts of adhesive cellulose gum and 7 parts of humectant sorbitol, and stir to form a thick mixture;

[0037] (3) Then add 1 part of surfactant sodium lauryl sulfate, 0.5 part of flavoring agent spearmint and the baking soda solution obtained in step (1) into the paste making pot successively, carry out scraper stirring, and leave after stirring for 0.5h pot to get the finished chitosan toothpaste.

Embodiment 2

[0039] (1) Dissolve 0.0002 parts of baking soda in 20 parts of purified water according to the formula ratio, and prepare a baking soda solution with pH=7-8 for later use;

[0040] (2) Put 3 parts of chitosan succinate into the paste making pot, add 8 parts of binder cellulose gum and 15 parts of humectant sorbitol, stir to form a thick mixture;

[0041] (3) Then add 3 parts of surfactant sodium lauryl sulfate, 3 parts of flavoring agent wintergreen mint and the baking soda solution obtained in step (1) in the paste making pot successively, carry out scraper stirring, and leave the pot after stirring for 1 hour. That is, the finished product of chitosan toothpaste is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com