A biocompatible built-in stent material

A technology of prosthetic materials and compositions, applied to intravascular stent materials and metals, can solve the problems of loss of EC function, vascular stenosis, poor clinical effect of endothelial inoculation, etc., and achieve the effect of inhibiting restenosis and avoiding restenosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

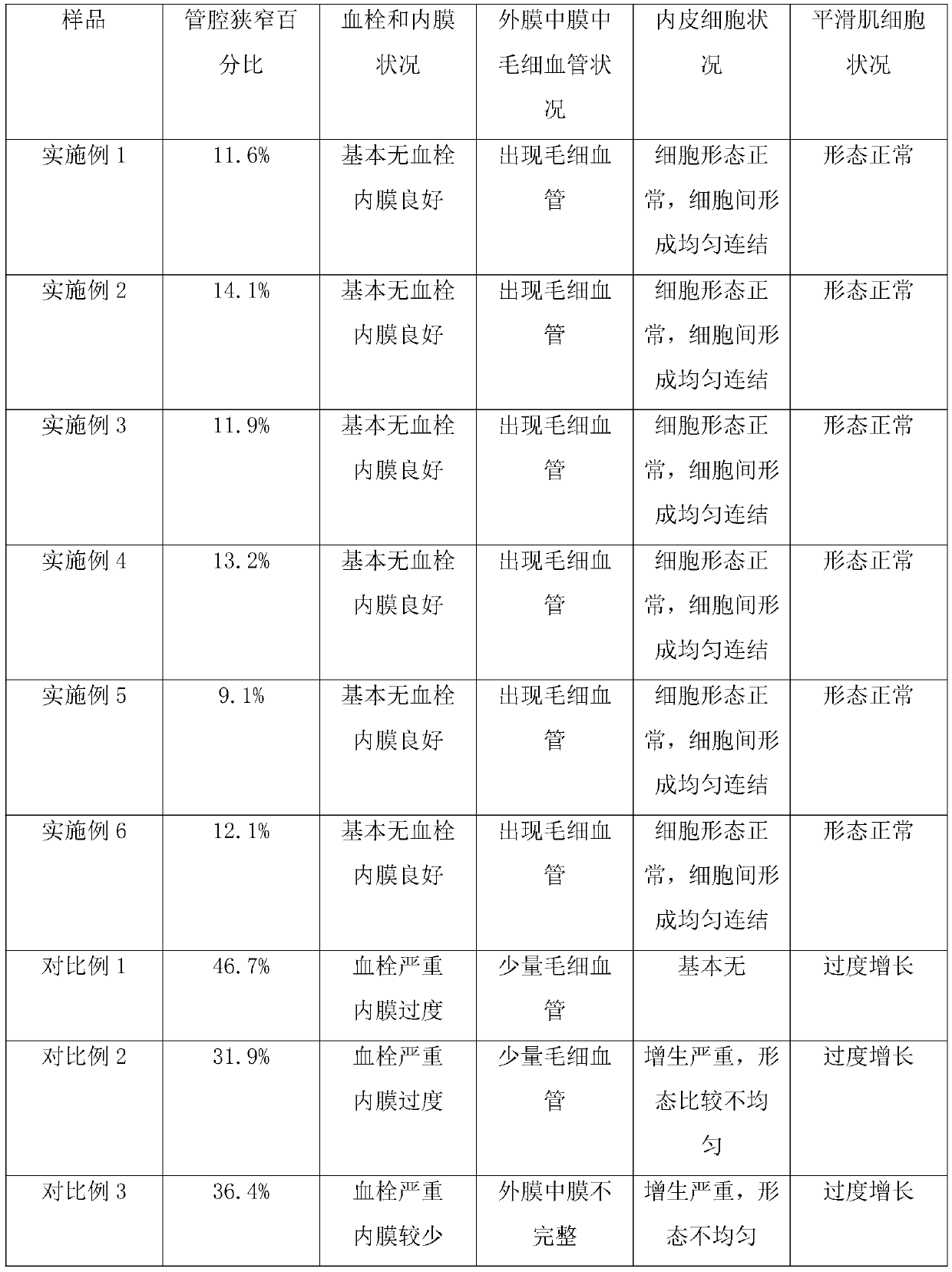

Embodiment 1

[0051] Fabrication of prostheses (preferably endovascular stents) with microcavities and short peptide coatings

[0052] Step 1: Obtain the matrix material of the prosthesis, which can degrade the tubular material of pure iron, and make it have holes connecting the inside and outside on the surface;

[0053] Step 2: Using laser engraving technology, obtain a microcavity in the thickness direction of the above-mentioned hole that runs through the prosthesis; the microcavity has a hemispherical profile, its diameter is 30 μm, and the depth of its bottom is the diameter of the hole 1 / 3 of that, and the total number of microcavities is 30;

[0054] Step 3: Using conventional techniques, obtain a composition in the form of microcapsules, said composition comprising gelatin as a "shell" and histidine-chelated iron as a "core", wherein the histidine-chelated iron is contained in the composition The weight content in is 0.5%, and the degradation period of described gelatin is about 7...

Embodiment 2

[0059] Fabrication of prostheses (preferably endovascular stents) with microcavities and short peptide coatings

[0060] The preparation process is the same as in Example 1, the difference is that: the matrix material used in step 1 is degradable polycaprolactone; the diameter of the microcavity in step 2 is 50 μm, and the depth dimension of the bottom is 1 / 4 of the diameter of the hole, The total number of microcavities is 40; the shell described in step 3 is chitosan, the degradation cycle is about 1 week, and the core is cysteine chelated iron, wherein the weight content of the core in the composition is 0.8%; The loading amount in step 4 was 8 μg.

Embodiment 3

[0062] Fabrication of prostheses (preferably endovascular stents) with microcavities and short peptide coatings

[0063] The preparation process is the same as in Example 1, the difference is that: the base material used in step 1 is degradable pure magnesium; the diameter of the microcavity in step 2 is 100 μm, and the depth dimension of the bottom is 1 / 5 of the diameter of the hole, and the microcavity The total number is 60; the shell in step 3 is collagen, and the degradation period is about 2 weeks, and the core is cysteine chelated iron, wherein the weight content of the core in the composition is 1.5%; in step 4, the load The amount is 10 μg; the sequences of the two short peptides in step 5 are sequence 3 and sequence 4 described above, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com