Air purification adsorbent and preparation method of air purification adsorbent

An air purification and adsorbent technology, which is used in the preparation of adsorbents and in the field of air purification adsorbents, can solve problems such as environmental pollution and difficult diffusion of pollutants, and achieve the effect of being conducive to absorption and excellent adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Its preparation method comprises the following steps:

[0039] (1) Dry and pulverize walnut shells, corn cobs, peony seed shells, and tea seed shells to obtain mixture A; pulverize maidenhair fern and Tianqing leaves to obtain mixture B;

[0040] (2) Take the pulverized mixture A, add sodium carboxymethylcellulose and water, and mix well;

[0041] Mixture A: water: sodium carboxymethylcellulose = 1:0.3-0.8:0.001-0.002, then add Bacillus subtilis, ferment at 35-38°C for 48-72h, record as fermentation product A;

[0042] Bacillus subtilis agent: mixture A=0.001:1, Bacillus subtilis is 1×10 8 -10 9 cfu / g;

[0043] Take the pulverized mixture B, add starch and water, and mix well;

[0044] Mixture B: starch: water = 1:0.02-0.06:0.5-0.8, then add Trichoderma harzianum, ferment at 35-38°C for 36-64h, and record it as fermentation product B;

[0045] Trichoderma harzianum inoculant: mixture B=0.002:1, Trichoderma harzianum is 2×10 8 -10 9 cfu / g;

[0046] The parts by w...

Embodiment 2

[0067] Different from the weight ratio of raw materials in Example 1, the method is the same as in Example 1.

[0068] The ratio of raw materials is:

[0069] Steelmaking slag 70-100 Activated carbon 15-30

[0070] Walnut shell 5-15 brown silk 10-20

[0071] Peony seed shell 10-30 corn cob 20-30

[0072] Tea seed shell 10-20 Bottom mud 20-30

[0073] Kaolin 25-35 Shale 15-25

[0074] Adiantum 3-10 Tian Qingye 5-15.

[0075] The specific parameters are as follows:

[0076] Mixture A: water: sodium carboxymethylcellulose = 1:0.3:0.001, then add Bacillus subtilis, and ferment at 35°C for 48 hours;

[0077] Mixture B: starch: water = 1:0.02:0.5, then add Trichoderma harzianum, and ferment at 35°C for 36 h.

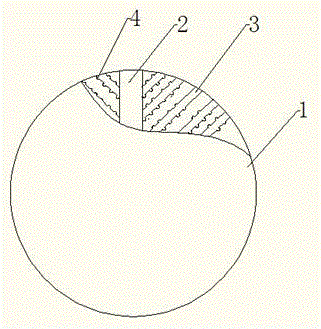

[0078] In the granulation step, the structure of the granulated particles is as follows: there is a cylindrical channel 2 in the center of the granule, and the channel 2 is used as the dividing line. There are multiple cavities 3 on both sides of the channel. These cavi...

Embodiment 3

[0080] Different from the weight ratio of raw materials in Example 1, the method is the same as in Example 1.

[0081] The ratio of raw materials is:

[0082] Steelmaking Slag 100 Activated Carbon 30

[0083] Walnut shell 15 brown silk 20

[0084] Peony seed shell 30 Corn cob 30

[0085] Tea seed shell 20 bottom mud 30

[0086] Kaolin 35 Shale 25

[0087] Adiantum 10 Tian Qing Ye 15 .

[0088] Mixture A: water: sodium carboxymethylcellulose = 1:0.8:0.002, then add Bacillus subtilis, and ferment at 38°C for 72 hours;

[0089] Mixture B: starch: water = 1:0.06:0.8, then add Trichoderma harzianum, and ferment at 38°C for 36 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com