Method and control system for controlling supply of desulfurizing agent for flue gas

A desulfurization agent and flue gas technology, applied in the field of flue gas desulfurization, can solve the problems of reduced utilization rate of limestone, unstable desulfurization efficiency, poor object adjustment characteristics, etc., and achieve stable desulfurization efficiency, stable desulfurization efficiency and desulfurization agent utilization rate, Immediate and accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

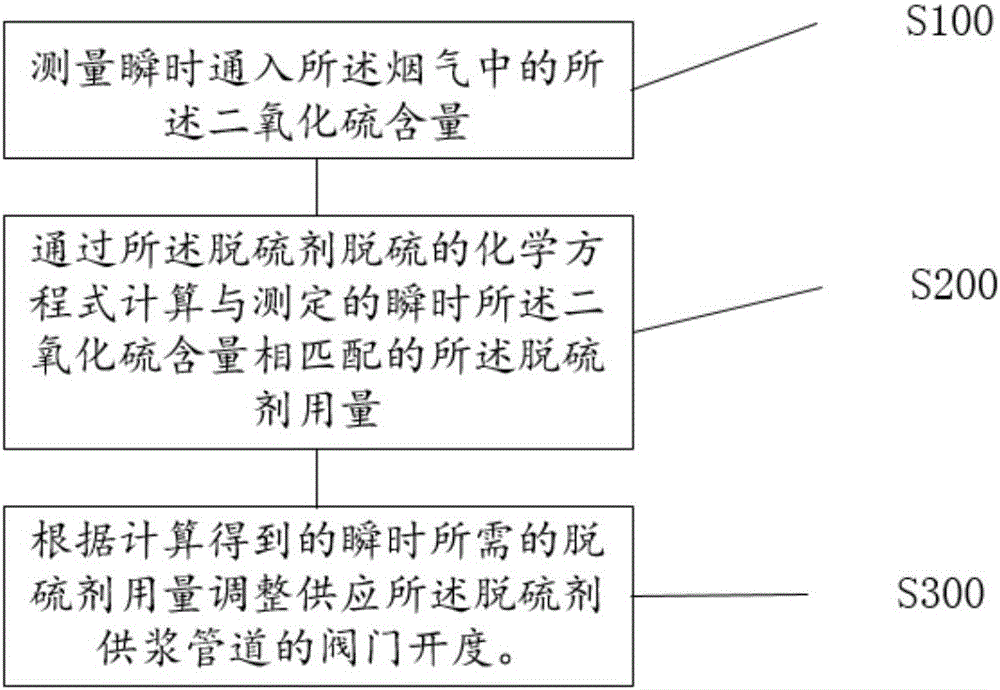

[0045] The desulfurizer is used to chemically react with the sulfur dioxide in the flue gas to desulfurize. The desulfurizer enters the absorption tower through the desulfurizer slurry supply pipeline. The embodiment of the method for controlling the supply of the flue gas desulfurizer is as follows: figure 1 shown, including the following steps:

[0046] S100, measuring the sulfur dioxide content that is instantaneously passed into the flue gas.

[0047] S200. Calculate the dosage of the desulfurizer that matches the measured instantaneous sulfur dioxide content according to the desulfurization chemical equation of the desulfurizer.

[0048] S300. Adjust the opening of the valve of the slurry supply pipeline for supplying the desulfurizing agent according to the calculated instantaneously required desulfurizing agent dosage.

Embodiment 2

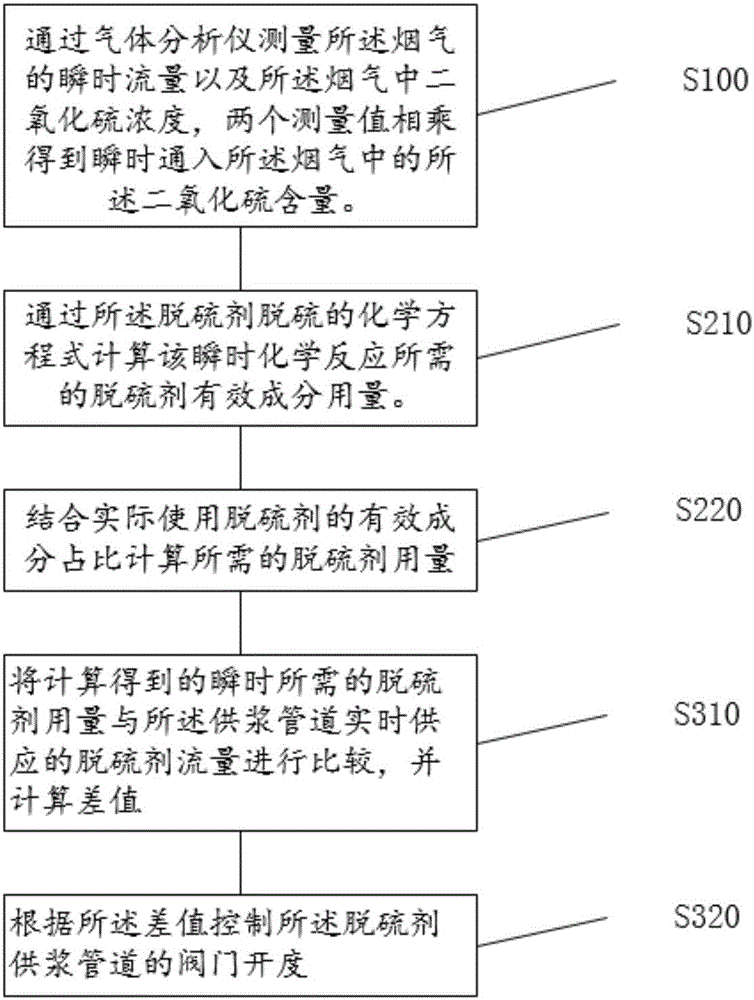

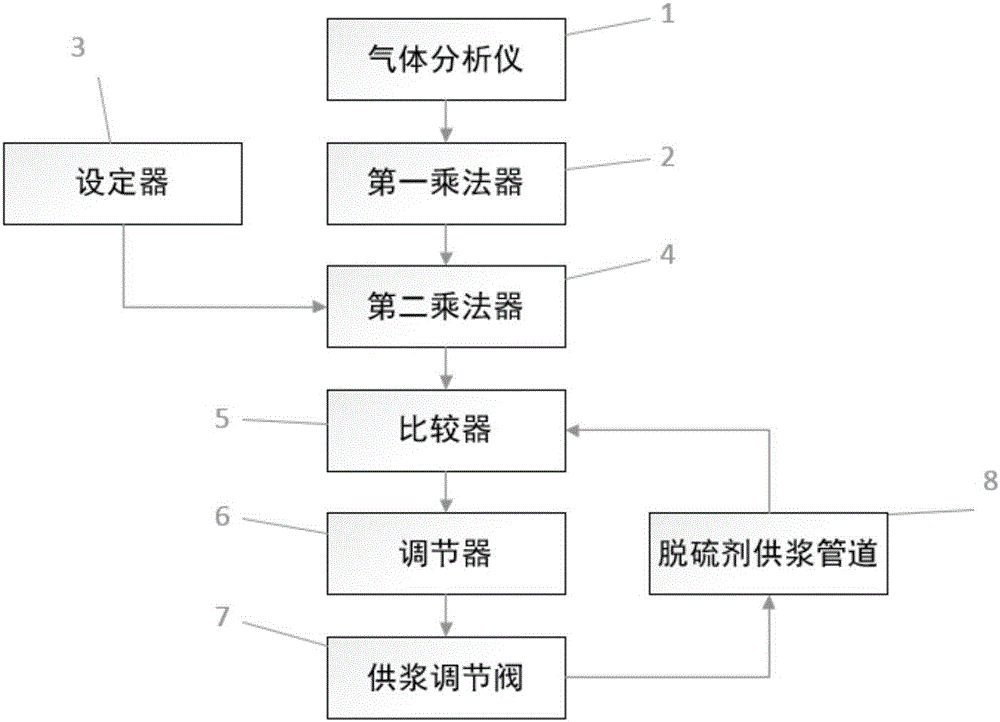

[0050] The desulfurizing agent is used to chemically react with the sulfur dioxide in the flue gas to desulfurize. The desulfurizing agent enters the absorption tower through the desulfurizing agent slurry supply pipeline. Taking the desulfurizing agent as limestone and the active ingredient of the desulfurizing agent as calcium carbonate as an example .

[0051] Embodiments of the method for controlling the supply of flue gas desulfurizers, such as figure 2 shown, including the following steps:

[0052] S100, measure the instantaneous flow rate of the flue gas and the concentration of sulfur dioxide in the flue gas by the gas analyzer 1, and multiply the two measured values to obtain the content of sulfur dioxide that is instantaneously passed into the flue gas.

[0053] S210, calculating the amount of calcium carbonate active ingredient required for the instantaneous chemical reaction through the desulfurization chemical equation of the desulfurizer.

[0054] Wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com