Single-pipe-structure fixed bed reactor for teaching experiment

A fixed-bed reactor and single-tube structure technology, which is applied in chemical instruments and methods, bulk chemical production, chemical/physical processes, etc., can solve the problems of complex reactor structure, high experimental cost, and long experimental time, and achieve Meet the needs of experimental teaching, the effect of short experimental time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described below.

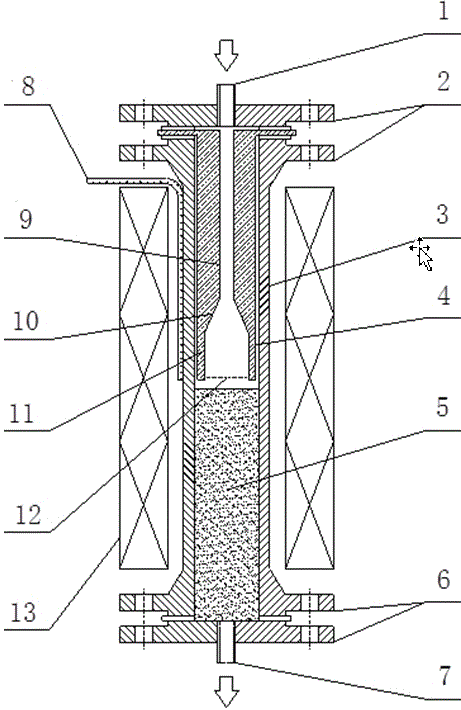

[0019] Implement a single-tube structure fixed-bed reactor for teaching experiments, the fixed-bed reactor is composed of material inlet 1, upper flange 2, cylinder 3, reaction tube 4, packing 5, lower flange 6, material outlet 7. Thermocouple 8, upper inner wall 9, middle inner wall 10, lower inner wall 11, stainless steel mesh 12 and heating device 13 thereof are configured and assembled using prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com