Special mixing device for phosphoric acid employing hemihydrate process

A technology of stirring device and semi-water method, which is applied to mixers with rotating stirring devices, mixer accessories, phosphorus compounds, etc., can solve the problems of poor stirring output, insufficient mixing, high slurry concentration, etc., and achieve increased stirring Area, mixing evenly, increasing the effect of projected area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

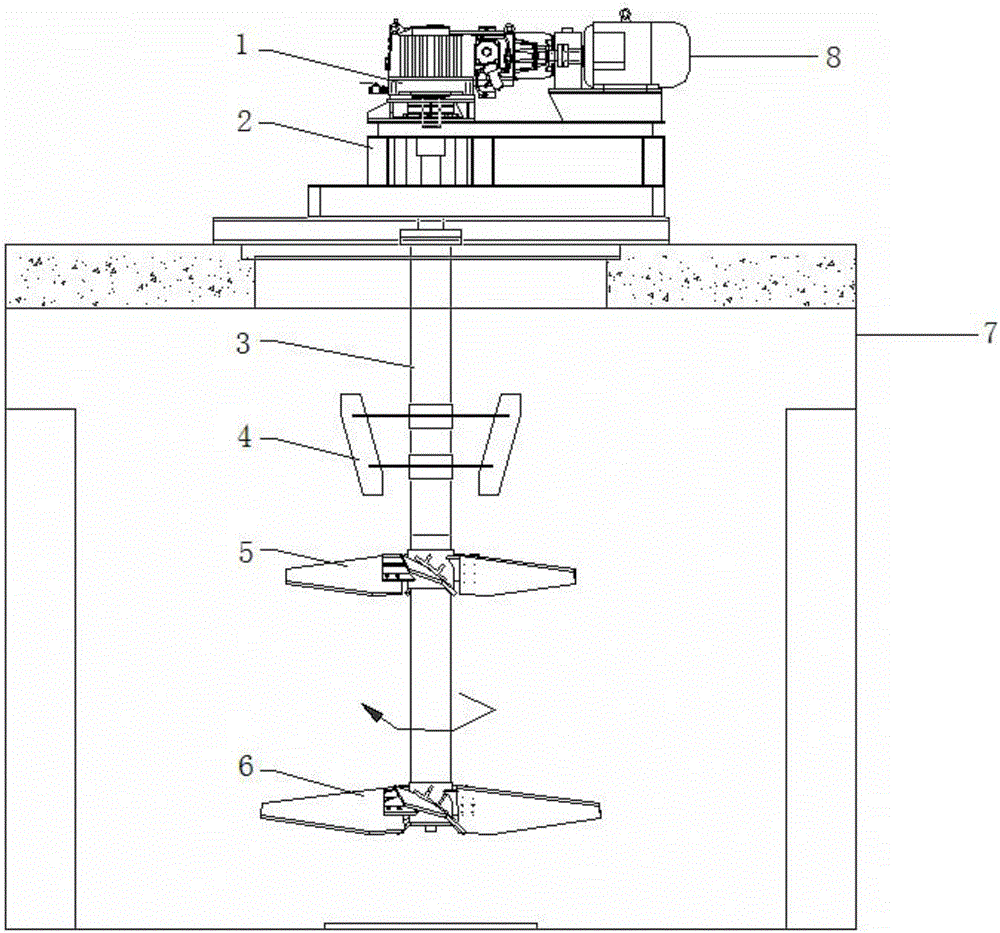

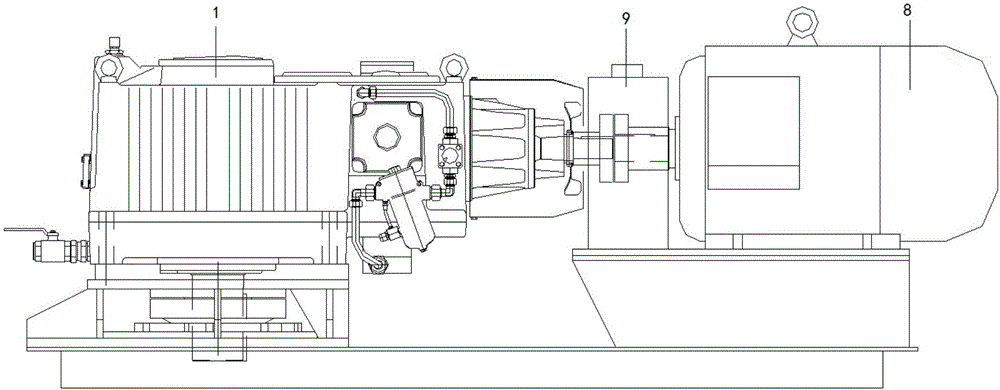

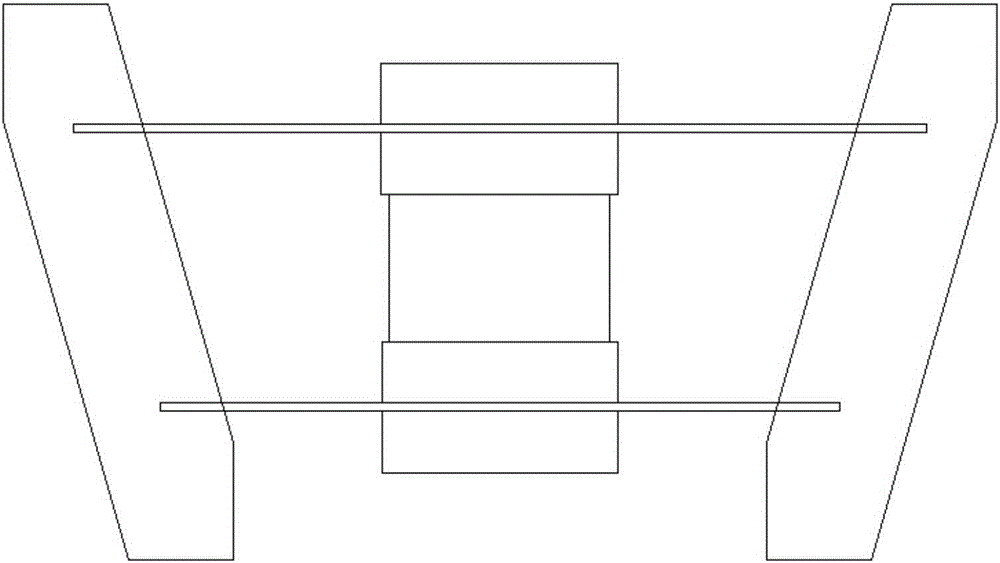

[0025] like Figure 1-2 Shown is a structural schematic diagram of a special stirring device for semi-aqueous phosphoric acid provided by the present invention, including a driving member, a frame and a stirring mechanism arranged in sequence, and the stirring mechanism is composed of a stirring bucket 7 and an axial stirring device with paddles. Shaft 3, the driving member includes a motor 8, a shaft coupling 9 and a speed reducer 1 arranged in sequence along the same horizontal axis, and the speed reducer 1 is a gear reducer, a worm gear reducer and / or a pulley reducer, so The frame is an annular steel frame, and one end of the frame connected to the stirring shaft is provided with a small annular steel frame with the stirring shaft 3 as the center of a circle and the inscribed diameter of the annular steel frame is smaller than the annular steel frame, so Stirring, 7 is a cylinder, the top is provided with a circular stepped through hole, the diameter of the upper part of t...

Embodiment 2

[0028] When the stirring device is working, the motor 8 is started, and the reducer 1 is driven to rotate through the coupling 9, and the reducer 1 drives the stirring shaft 3 to rotate at the same time. The rotation, wide and angled paddle setting can overcome the characteristics of high concentration and high viscosity of phosphoric acid slurry in the mixing chamber, and increase the stirring output effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com