Forging method for high temperature resistance titanium alloy large-size bars used for engines

A titanium alloy, high-temperature-resistant technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve problems such as material cracking, small deformation, and significant difference in thermal conductivity between the center and edge of the bar. , to achieve the effect of avoiding cracks and uneven deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

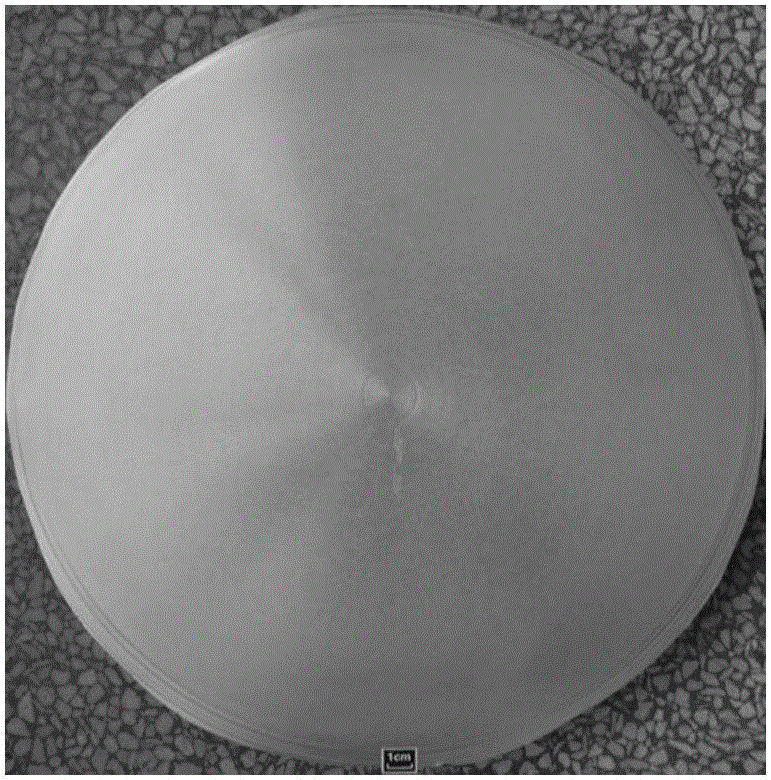

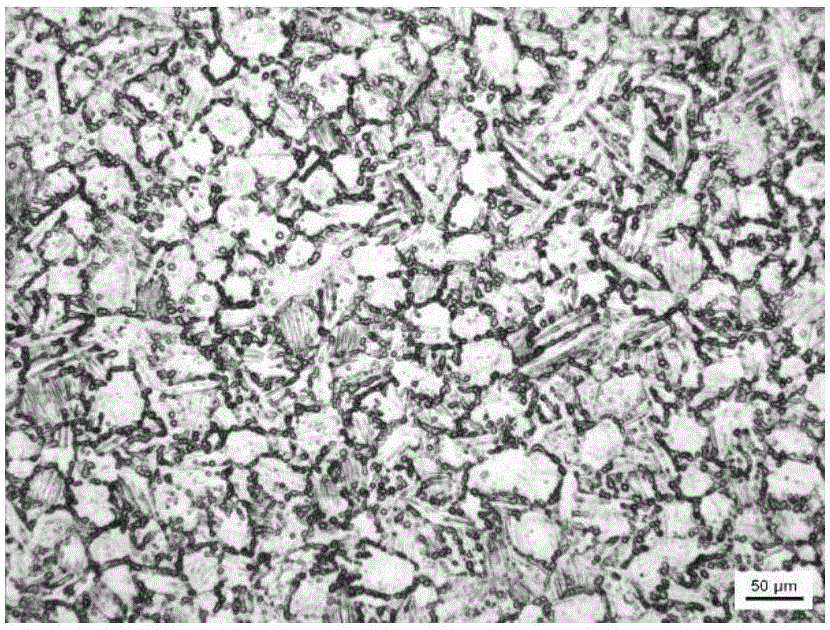

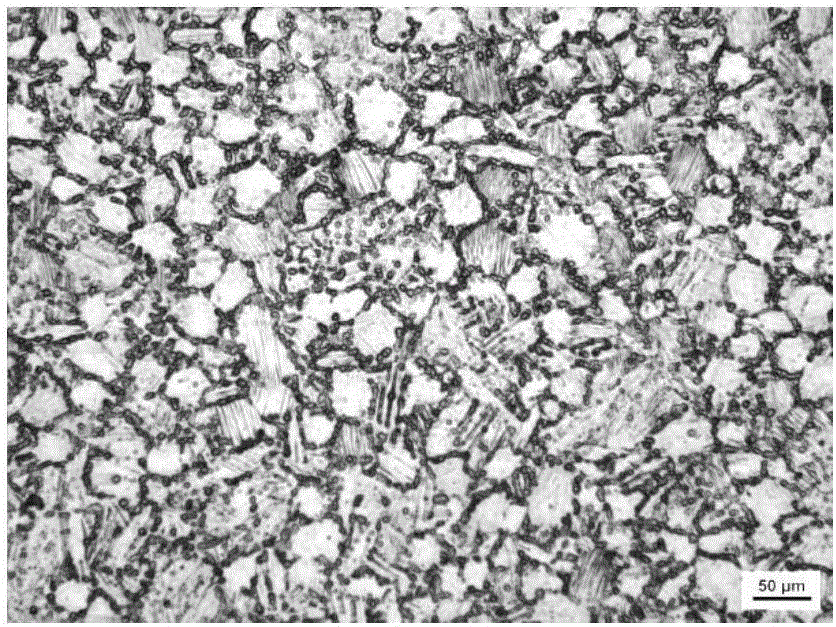

Image

Examples

Embodiment 1

[0040] Step 1, blank forging:

[0041] The billet opening of the ingot is completed by three-fire forging. The heating temperature of the first fire forging is 1150°C. After heating for 10 hours, it is out of the furnace. The ingot is elongated and deformed once. The billet opening temperature of the second fire and the third fire is 1090°C and 1070°C, each fire is heated and kept for 8 hours, after being out of the furnace, it is upsetting and drawing, and after drawing, it is processed in all directions. The upsetting and drawing ratio of each fire is 2.2, Water quenching is used after forging.

[0042] Step 2, Intermediate Forging:

[0043] The ingot after the billet forging in step 1 is isothermally re-forged seven times in the two-phase zone, and the heating temperature for each fire is selected to be 50°C (1000°C) below the phase transition point to prevent the forging temperature from exceeding the thermal processing window. All the fires are wrapped with 50mm thick a...

Embodiment 2

[0047] Step 1, blank forging:

[0048]The ingot opening is completed by three-fire forging. The heating temperature of the first fire forging is 1200°C. After heating for 8 hours, it is out of the furnace. The ingot is elongated and deformed. , to avoid deformation dead zone at the edges and corners, the forging ratio is 1.6. The billet opening temperature of the second fire and the third fire is 1100°C and 1080°C, each fire is heated for 6 hours, and the upsetting and drawing are completed after being out of the furnace. During the period, water quenching is used after forging.

[0049] Step 2, Intermediate Forging:

[0050] The ingot after step 1 billet forging is subjected to isothermal reforging in the two-phase area, and the heating temperature for each firing is selected to be 70°C (980°C) below the phase transition point to avoid the forging temperature exceeding the thermal processing window. All are wrapped with asbestos with a thickness of 20mm. After the material...

Embodiment 3

[0054] Step 1, blank forging:

[0055] The ingot opening is completed by three-fire forging. The heating temperature of the first fire forging is 1250°C. After heating for 9 hours, it is out of the furnace. The ingot is elongated and deformed once. The billet opening temperature of the second fire and the third fire is 1110°C and 1090°C. Each heat is heated and kept for 7 hours. After being out of the furnace, it is upsetting and stretched. Water quenching is used after forging.

[0056] Step 2, Intermediate Forging:

[0057] The ingot after blank forging in step 1 is isothermally re-forged seven times in the two-phase zone, and the heating temperature for each fire is selected to be 60°C (990°C) below the phase transition point to prevent the forging temperature from exceeding the thermal processing window. All the fires are wrapped with 30mm thick asbestos. After the materials are out of the furnace, they are subjected to upsetting, elongation and inversion in sequence. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com