Nitrogen protection method for SCR method copper wire blank pouring, and corresponding structure

A technology of nitrogen protection and copper wire billet, which is applied in the field of casting copper wire billet, can solve the problems of copper liquid splashing on the liquid surface, easy generation of air, broken wires of inclusions, uneven oxygen content, oxide particles, etc., to ensure quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

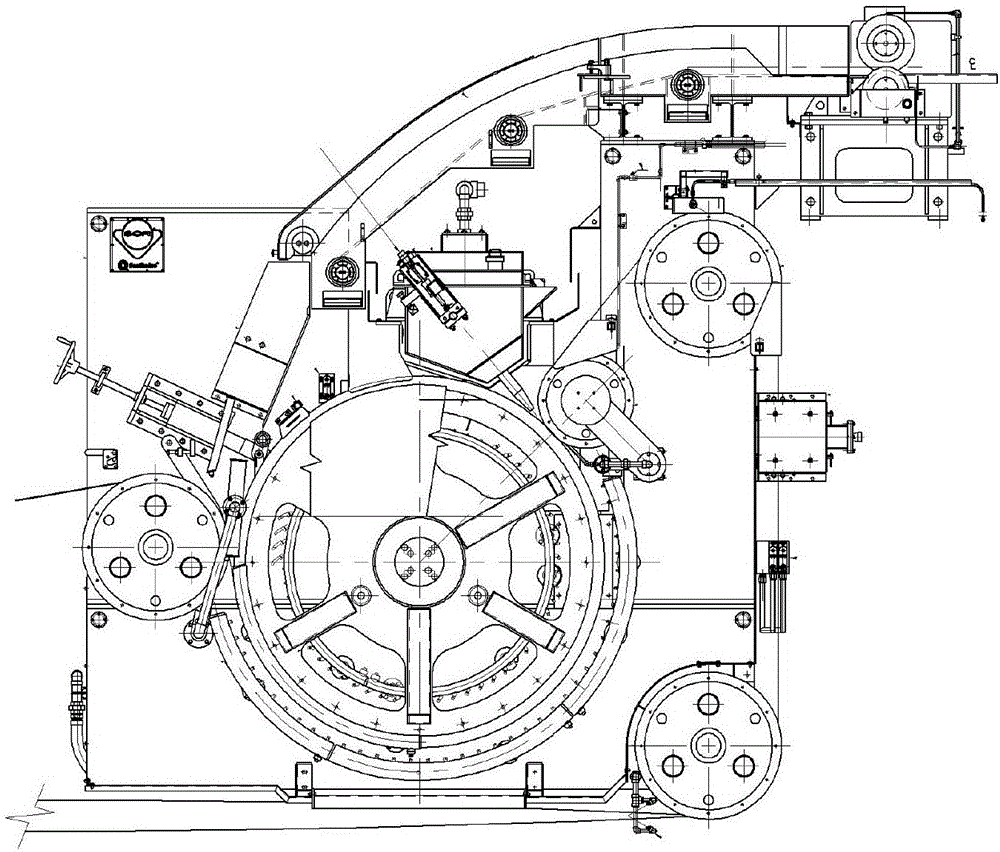

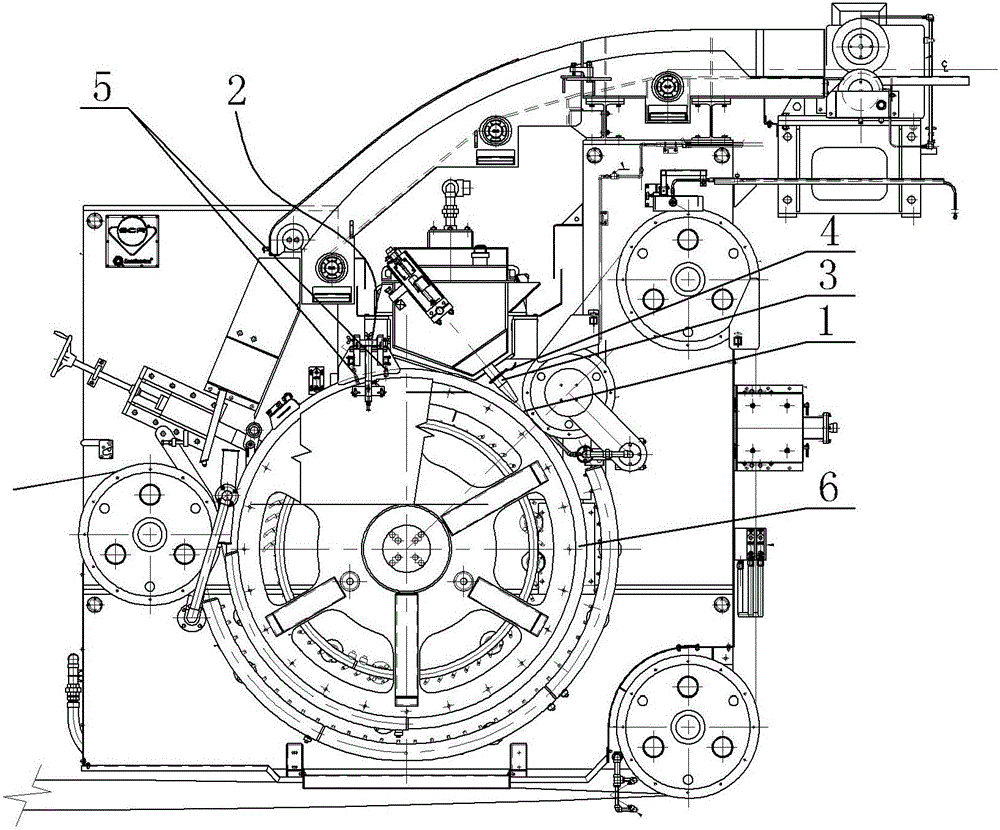

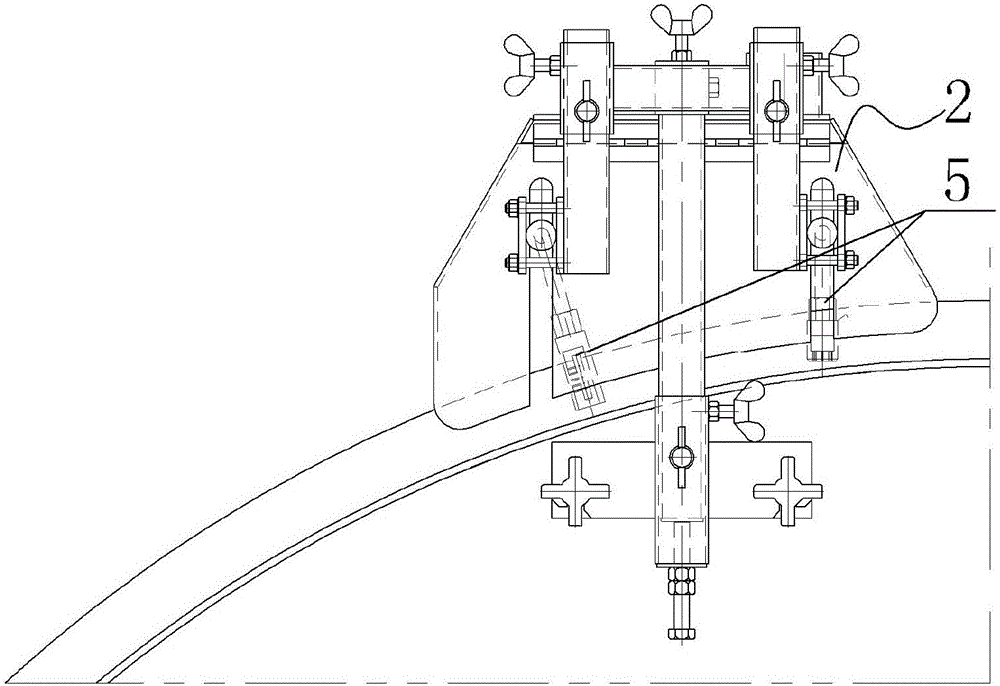

[0036] Specific embodiment: The height of the pouring tube bottom of the original SCR3000 equipment from the liquid surface of the molten pool is 160mm, the diameter of the column flow is Φ23.48, and the speed is 5.66 m / s. A negative pressure is formed around the column flow, and the air is easily involved in the column. flow; in addition, the high-speed flow of the column flow, the surface of the pouring liquid (cross-sectional area of 3800mm 2 ) to form an impact, causing the copper liquid on the liquid surface to splash, and 3 to 10 copper particles with a diameter of Φ0.5 to 2.5 fly out every second (the splashed copper liquid will solidify into copper particles when it encounters air), resulting in pores and oxygen in the billet. The amount of uneven oxide particles, the product Φ8.0mm low-oxygen copper rod is prone to air, inclusions and broken wires during the process of drawing filaments. Generally, after drawing to ¢0.127mm, the disconnection rate of copper wire is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com