Welding method and welding structure of lithium ion battery covers

A lithium-ion battery, welding method technology, applied in welding/welding/cutting items, battery caps/end caps, secondary batteries, etc., can solve the problems of difficult and precise control, melting through, explosion, etc., to reduce the number of times The effect of producing high-quality batteries, resisting the falling off of the tabs, and improving the welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

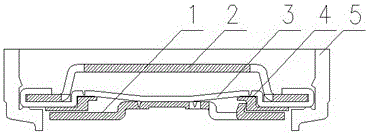

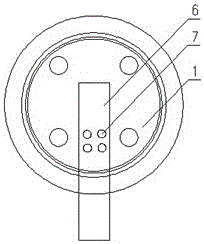

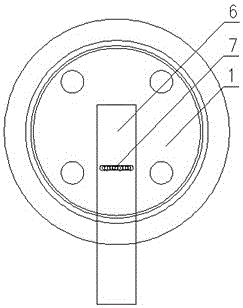

[0017] A 18650 battery was fabricated using the invented method, as follows.

[0018] Use the cap and positive tab that are normally used by the battery. The width of the tab is 2.5 mm. The laser welding power is 100W, and the welding is performed by superimposing 3 solder joints. The superposition distance is that the center distance of the solder joints is equal to half the diameter of the solder joints. The welding strength is tested by tensile force, and the tensile force reaches more than 1200 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com