A method for eutectic welding to solve pind detection

A technology of eutectic welding and PIND, which is applied in the field of eutectic welding to solve PIND detection. It can solve the problems of affecting PIND detection, reducing product reliability, and high welding strength, so as to reduce the number of free moving particles, improve reliability, and avoid alloy oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

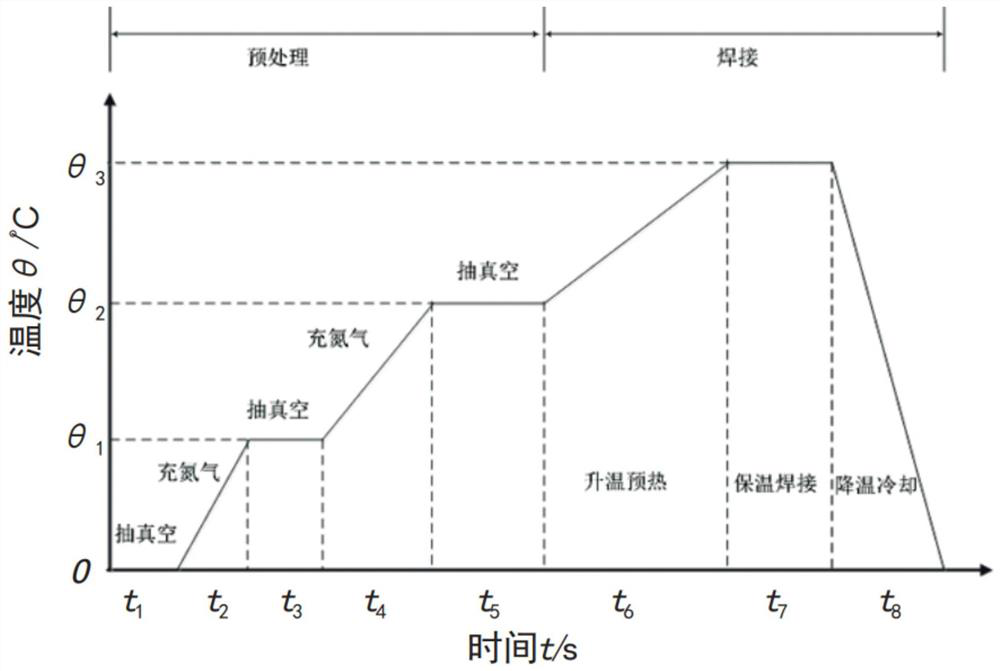

[0017] The following will combine figure 1 A method of eutectic soldering in an embodiment of the present invention for solving unqualified PIND detection will be described in detail.

[0018] refer to figure 1 As shown, a method for eutectic welding to solve PIND detection provided by the embodiment of the present invention includes:

[0019] (1) Cut the size of the tin-silver-copper soldering sheet for eutectic welding according to the size of the ceramic substrate, wherein the size of the tin-silver-copper soldering sheet is smaller than the size of the ceramic substrate.

[0020] (2) Clean the cut tin-silver-copper solder sheet with deionized water, then use ultrasonic cleaning in ethanol solution, and finally dry it for later use.

[0021] For example, according to the size of the ceramic substrate, tin-silver-copper solder sheets slightly smaller than the size of the ceramic substrate are cut, and then cleaned with deionized water, and then ultrasonically cleaned with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com