Laser welding method

A technology of laser welding and welding speed, applied in laser welding equipment, welding medium, welding equipment and other directions, can solve the problems of easy belt breakage, affecting the quality of steel grades, unstable welding performance, etc., to reduce the probability of belt breakage, welding The effect of full seam and improved welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

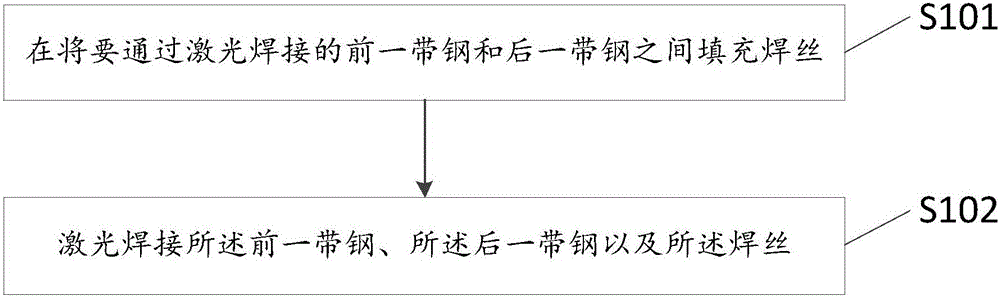

Method used

Image

Examples

Embodiment 1

[0045] In Example 1, the raw material composition for hot rolling includes 0.095% C, 2.3% Mn, 0.35% Si, 0.013% P, and 0.008% S. The strip specification is 3.5mm*1200mm. A welding wire consisting of 0.07%C, 0.87%Si, 1.45%Mn, 0.012%P, 0.006%S, 0.13%Cu, 0.006%Ni, 0.045%Cr and 97.411%Fe was filled between the front and rear strips. During laser welding, welding is carried out according to the welding power of 11000W, welding speed of 4m / min, wire feeding speed of 4m / min, and annealing current of 120A. The finished product manufactured from the final strip steel is a dual-phase steel of 1000MPa, with a tensile strength of 1000MPa.

[0046] figure 2 The metallographic structure diagram of the above-mentioned 1000MPa grade dual-phase steel is shown. image 3 Shown is the metallographic diagram of the structure of the weld seam obtained by welding the strip steel in Example 1 by using the existing laser welding method. Figure 4 The metallographic diagram of the structure of the ...

Embodiment 2

[0048] In Example 2, the raw material components for hot rolling include 0.090% C, 2.23% Mn, 0.32% Si, 0.012% P, and 0.007% S. The specification of strip steel is 3.5mm*1088mm. A welding wire consisting of 0.07%C, 0.87%Si, 1.45%Mn, 0.012%P, 0.006%S, 0.13%Cu, 0.006%Ni, 0.045%Cr and 97.411%Fe was filled between the front and rear strips. During laser welding, welding is carried out according to the welding power of 11000W, welding speed of 4.5m / min, wire feeding speed of 4.5m / min, and annealing current of 130A. The final tensile strength of the finished product reaches 1011MPa.

[0049] Image 6 Shown is the microstructure metallographic diagram of the weld seam obtained by welding the strip steel in Example 2 by using the existing laser welding method. Figure 7 Shown is the metallographic diagram of the structure of the weld seam obtained by adopting the method of the laser weld seam in the second embodiment. It can be seen that the welding seam is fully filled by the meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap