Fixture device for laser processing of connecting rod cracking groove

A technology of laser processing and clamping device, which is applied in auxiliary devices, manufacturing tools, metal processing, etc., can solve the problems of uneven groove depth and inaccurate positioning of cracking grooves, and achieve the effect of uniform groove depth and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

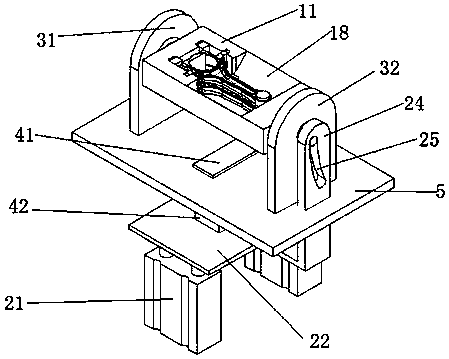

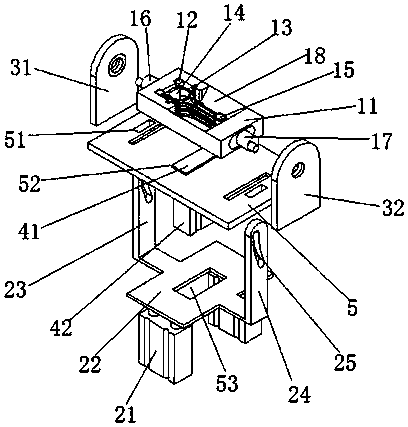

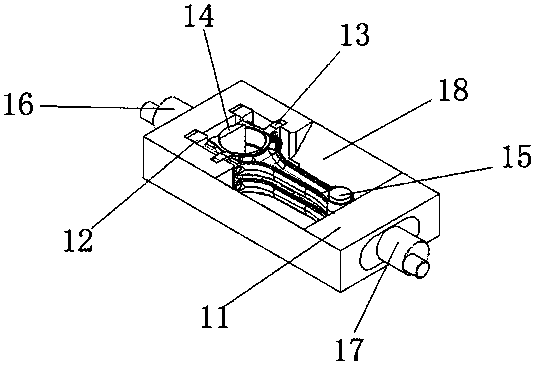

[0023] The schematic diagram of the laser processing fixture device for the connecting rod cracking groove in this embodiment is as follows Figure 1 to Figure 2 As shown, it includes a control unit, a clamp plate assembly, a front support plate 31, a rear support plate 32, a carrying platform 5, a first driving device 21, a push-pull plate 22, a front push-pull block 23 and a rear push-pull block 24; the clamp plate assembly is used for Fix the automobile connecting rod; the front support plate 31 and the rear support plate 32 are all fixed on the carrying platform 5, and the carrying platform 5 is provided with two first through holes 51; the push-pull plate 22 is located under the carrying platform 5, and the front push-pull block 23 and the bottom of the rear push-pull block 24 are respectively fixed on the two ends of the push-pull plate 22, and the front push-pull block 23 and the rear push-pull block 24 are movable and embedded in the first through hole 51 respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com