Process of producing camera glass

A production process and camera technology, applied in the printing process, the printing and printing of special varieties of printed matter, can solve the problems of construction danger, secondary damage to the product, single printing process, etc., and achieve the production qualification rate without pollution and exquisite patterns. or effect, effect with simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

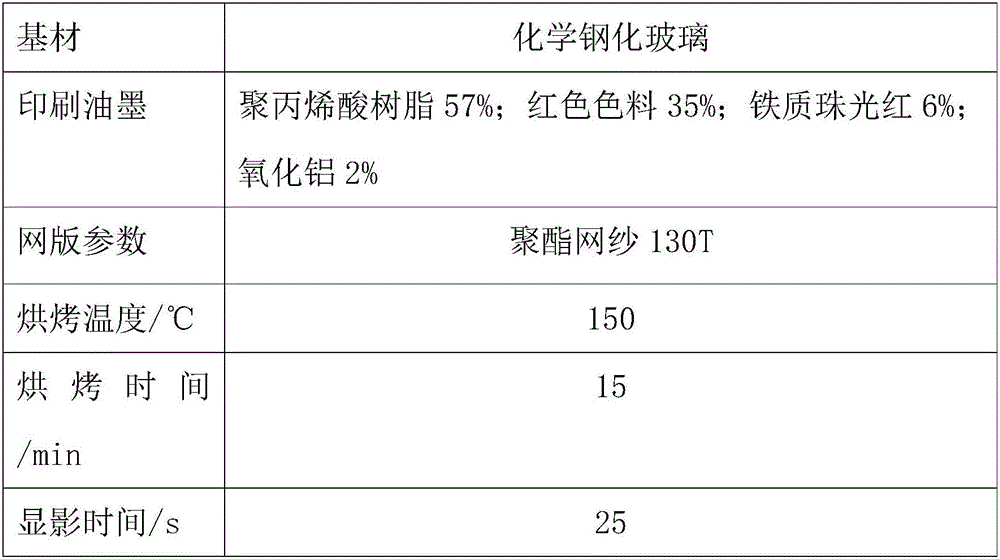

Embodiment 1

[0037] The invention provides a technical solution: a camera glass production process, comprising the following steps:

[0038] S1: Draw the mold: use CAD, COREIDRAW software to design, and output the pattern, and inlay the soft magnet on the iron plate according to the pattern, so as to make a 3D mold;

[0039] S2: Prepare ink: use iron pearl effect powder, glass ink resin, colorant and aluminum oxide to mix and match to prepare 3D ink;

[0040] S3: Make the screen: use CAD and COREIDRAW software to design, output the pattern and make the film, and then develop the film pattern on the screen. The developing temperature is 33°C and the pattern developing time is 25s.

[0041] S4: Processed glass: Clean the camera glass to be printed. The optical tempered glass is cut, edged, cleaned, and optically tempered. The tempering temperature is 400°C and the tempering time is 3.5 hours.

[0042] S5: Debug equipment: debug printing equipment and drying equipment;

[0043] S6: Screen a...

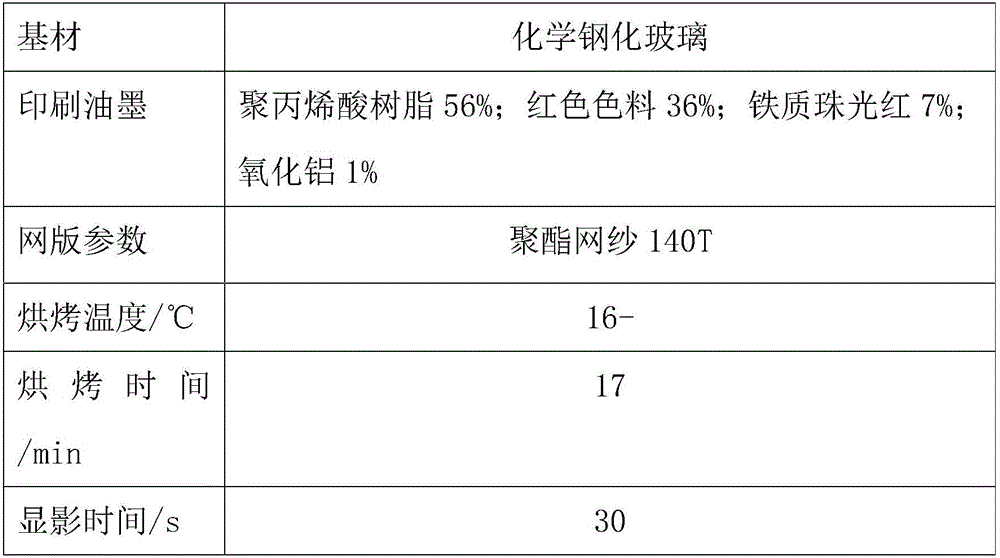

Embodiment 2

[0071] The invention provides a technical solution: a camera glass production process, comprising the following steps:

[0072] S1: Draw the mold: use CAD, COREIDRAW software to design, and output the pattern, and inlay the soft magnet on the iron plate according to the pattern, so as to make a 3D mold;

[0073] S2: Prepare ink: use iron pearl effect powder, glass ink resin, colorant and aluminum oxide to mix and match to prepare 3D ink;

[0074] S3: Make the screen: use CAD and COREIDRAW software to design, output the pattern and make the film, and then develop the film pattern on the screen. The developing temperature is 34°C, and the pattern developing time is 30s.

[0075] S4: Processed glass: Clean the camera glass to be printed. The optical tempered glass is cut, edged, cleaned, and optically tempered. The tempering temperature is 415°C and the tempering time is 4 hours;

[0076] S5: Debug equipment: debug printing equipment and drying equipment;

[0077] S6: Screen an...

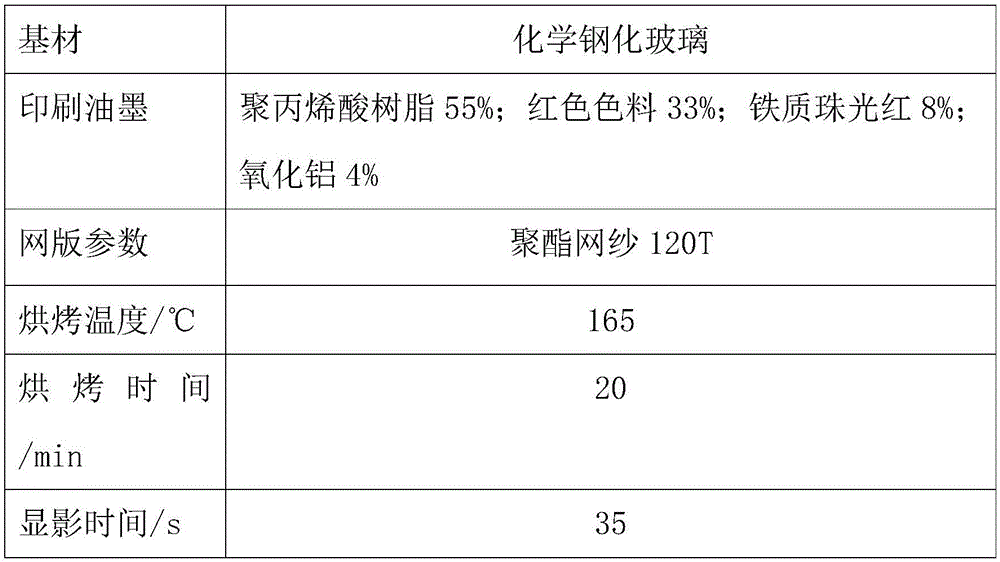

Embodiment 3

[0105] The invention provides a technical solution: a camera glass production process, comprising the following steps:

[0106] S1: Draw the mold: use CAD, COREIDRAW software to design, and output the pattern, and inlay the soft magnet on the iron plate according to the pattern, so as to make a 3D mold;

[0107] S2: Prepare ink: use iron pearl effect powder, glass ink resin, colorant and aluminum oxide to mix and match to prepare 3D ink;

[0108] S3: Make the screen: use CAD and COREIDRAW software to design, output the pattern and make the film, and then develop the film pattern on the screen. The developing temperature is 35°C and the pattern developing time is 35s.

[0109] S4: Processed glass: clean the camera glass to be printed, the optical tempered glass is cut, edged, cleaned, and optically tempered. The tempering temperature is 430°C and the tempering time is 5 hours;

[0110] S5: Debug equipment: debug printing equipment and drying equipment;

[0111] S6: Screen and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com