Spiral-dislocation-driven preparation method for growing spiral laminar tin selenide nanosheets

A screw dislocation, tin selenide technology, applied in nanotechnology, binary selenium/tellurium compounds, metal selenide/telluride and other directions, can solve the problems of tin selenide nanosheets that are rarely studied, and achieve low cost, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

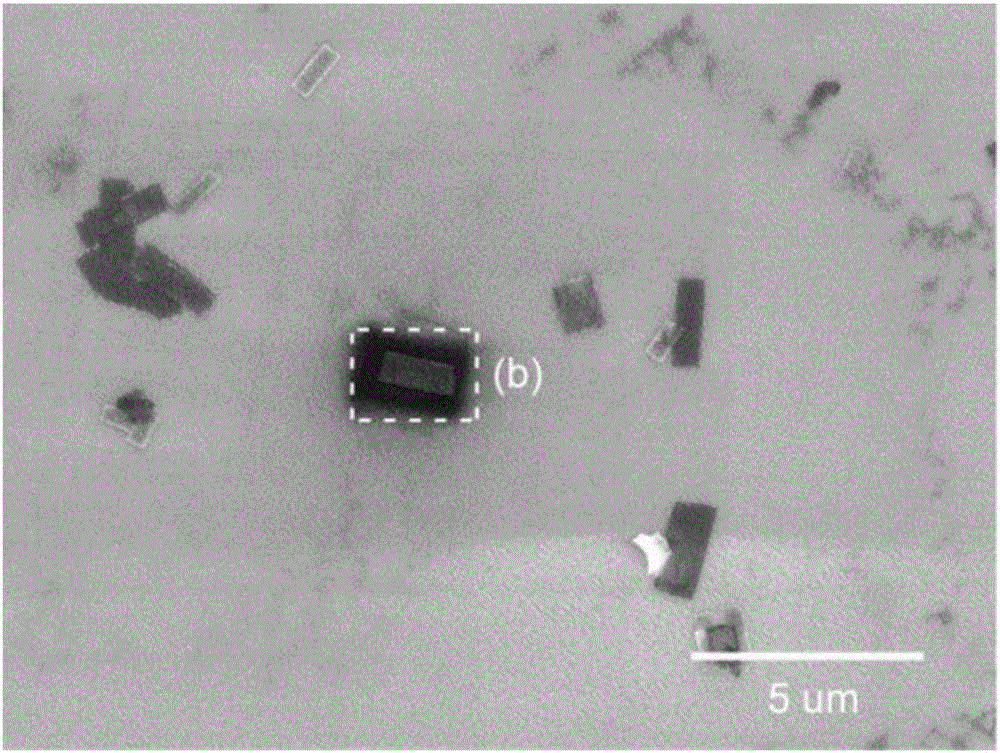

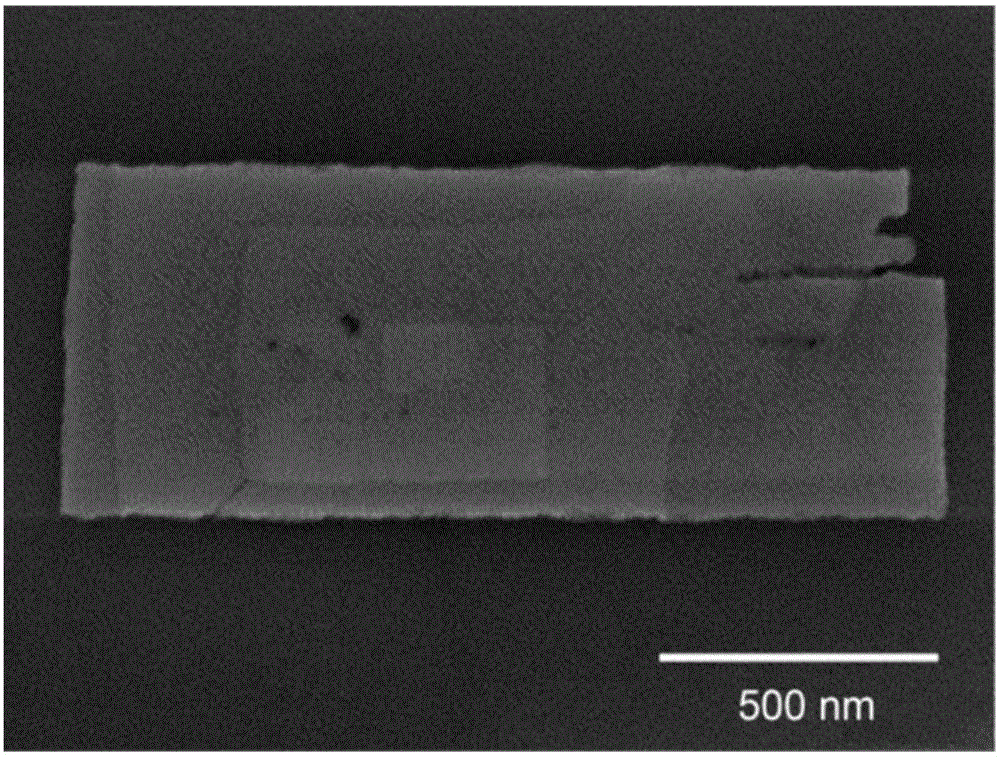

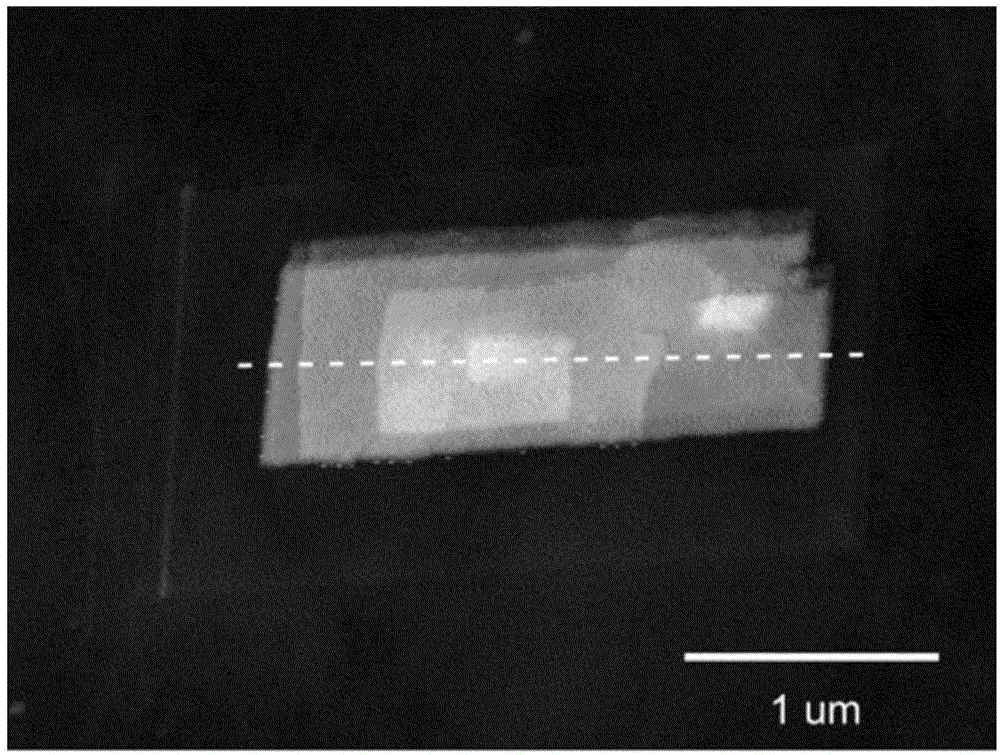

Image

Examples

preparation example Construction

[0032] A method for preparing helical layered tin selenide nanosheets driven by helical dislocations, comprising the following steps:

[0033] 1) At room temperature, configure a benzyl alcohol solution of stannous chloride with a concentration of 0.4-1.0mmol / L, selenium dioxide with a concentration of 0.4-1.0mmol / L and polyvinylpyrrolidone with a concentration of 160-400g / L , and mix well;

[0034] 2) Transfer the uniformly mixed solution to a three-neck round bottom flask for sealing and stirring, and slowly pass in protective gas;

[0035] 3) In a protective gas atmosphere, heat the solution to 190-210°C and keep it at a constant temperature for 12-18 hours;

[0036] 4) After cooling the solution naturally to room temperature, centrifuge at a speed of 900-1100rpm for 12-18min, wash and filter the centrifuged product with absolute ethanol, and store it in absolute ethanol solution to obtain a helical dislocation-driven Growth of helical layered tin selenide nanosheets.

...

Embodiment 1

[0044] A method for preparing helical layered tin selenide nanosheets driven by helical dislocations, comprising the following steps:

[0045] 1) At room temperature, configure stannous chloride with a concentration of 0.8mmol / L, selenium dioxide with a concentration of 0.8mmol / L, and polyvinylpyrrolidone with a concentration of 320g / L, and the ratio is 1mmol / L: 1 mmol / L L: 400g / L benzyl alcohol solution, and mix well;

[0046] 2) Transfer the uniformly mixed solution to a three-necked round-bottom flask for sealing and stirring, and slowly inject nitrogen;

[0047] 3) In a nitrogen atmosphere, heat the solution to 200°C and keep it at a constant temperature for 12 hours;

[0048] 4) After cooling the solution to room temperature naturally, centrifuge at 1000rpm for 10min, wash and filter the centrifuged product with absolute ethanol, and store it in absolute ethanol solution, that is, to obtain a helical periodicity with atomic thickness The helical dislocation drives the g...

Embodiment 2

[0050] A method for preparing helical layered tin selenide nanosheets driven by helical dislocations, comprising the following steps:

[0051] 1) At room temperature, configure stannous chloride with a concentration of 0.4mmol / L, selenium dioxide with a concentration of 0.4mmol / L, and polyvinylpyrrolidone with a concentration of 160g / L, and the ratio is 1mmol / L: 1 mmol / L L: 400g / L benzyl alcohol solution, and mix well;

[0052] 2) Transfer the uniformly mixed solution to a three-neck round bottom flask for sealing and stirring, and slowly inject argon;

[0053] 3) In an argon atmosphere, heat the solution to 210°C and keep it at a constant temperature for 18 hours;

[0054]4) After the solution was naturally cooled to room temperature, it was centrifuged at 900rpm for 12 minutes, and the centrifuged product was washed and filtered with absolute ethanol, and stored in absolute ethanol solution, that is, a helical periodicity with atomic thickness was obtained. The helical dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com