Preparation method of ultra-fine diamond-graphene composite material

A composite material and diamond technology, which is applied in the field of preparation of ultrafine diamond-graphene composite materials, can solve the problems of easy accumulation and other problems, and achieve the effects of strong controllability, enhanced mechanical and electrical properties, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

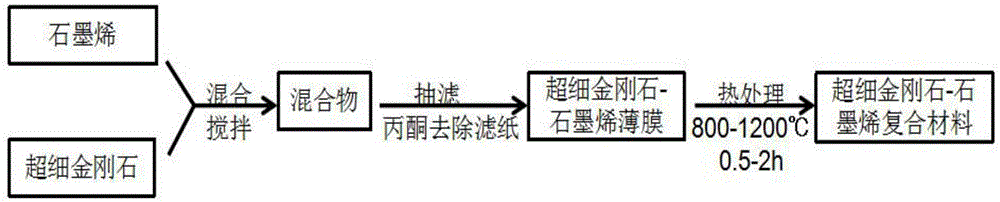

Method used

Image

Examples

Embodiment 1

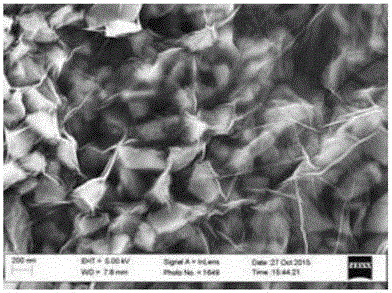

[0022] The ultrafine diamond with a size of 50nm and the graphene are mixed in water at a mass ratio of 0.6 to form a dispersion, wherein the total concentration of the ultrafine diamond and graphene is 0.2wt%. The dispersion is filtered through a suction filter to form a membrane. The filter paper used for suction filtration is water-based filter paper with a pore size of 0.15 μm. After suction filtration, the filter layer was taken out together with the filter paper, soaked in acetone solution to remove the filter paper, and obtained an ultrafine diamond and graphene mixed film with a film thickness of 1 μm. The film was placed in a quartz tube of a tube furnace and heat-treated at 800° C. for 0.5 h to obtain an ultrafine diamond-graphene composite material. The ultrafine diamond-graphene composite material is used in supercapacitors. figure 2 It is the scanning electron micrograph of the ultrafine diamond-graphene composite material prepared in this embodiment.

Embodiment 2

[0024] The ultrafine diamond with a size of 1 μm and graphene were mixed in water according to the mass ratio of Example 1 to form a dispersion, wherein the total concentration of ultrafine diamond and graphene was 2wt%. The dispersion is filtered through a suction filter to form a membrane. The filter paper used for suction filtration is water-based filter paper with a pore size of 0.8 μm. After suction filtration, take out the filter layer together with the filter paper, soak in acetone solution to remove the filter paper, and obtain an ultrafine diamond and graphene mixed film with a film thickness of 0.1mm. The film was placed in a quartz tube of a tube furnace and heat-treated at 1200°C for 2 hours to obtain an ultrafine diamond-graphene composite material. The ultrafine diamond-graphene composite material is applied to ultrafine abrasive tools.

Embodiment 3

[0026] Ultrafine diamond with a size of 100nm and graphene are mixed in water at a mass ratio of 0.2 to form a dispersion, wherein the total concentration of ultrafine diamond and graphene is 0.5wt%. The dispersion is filtered through a suction filter to form a membrane. The filter paper used for suction filtration is water-based filter paper with a pore size of 0.3 μm. After suction filtration, the filter layer was taken out together with the filter paper, soaked in acetone solution to remove the filter paper, and obtained an ultrafine diamond and graphene mixed film with a film thickness of 100 μm. The film was placed in a quartz tube of a tube furnace and heat-treated at 1000° C. for 1.5 h to obtain an ultrafine diamond-graphene composite material. The ultrafine diamond-graphene composite material is applied to a field emission display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com