Method and device for municipal sewage treatment enhancement operation with intermittent aeration of biochemical tank

A technology of urban sewage and operating equipment, applied in the field of water treatment, can solve the problems of easy running of finely crushed sludge flocs, increase of secondary sedimentation load, poor regulation, etc., to reduce sludge treatment output, reduce operating energy consumption, The effect of increasing biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

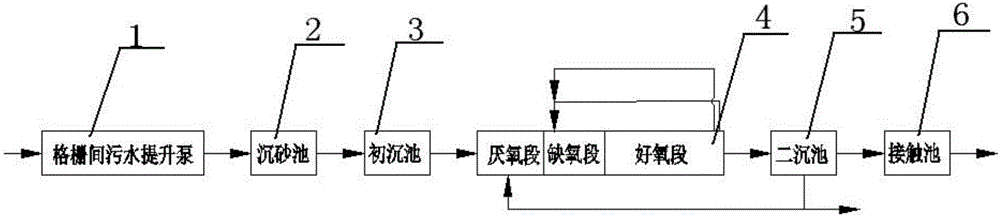

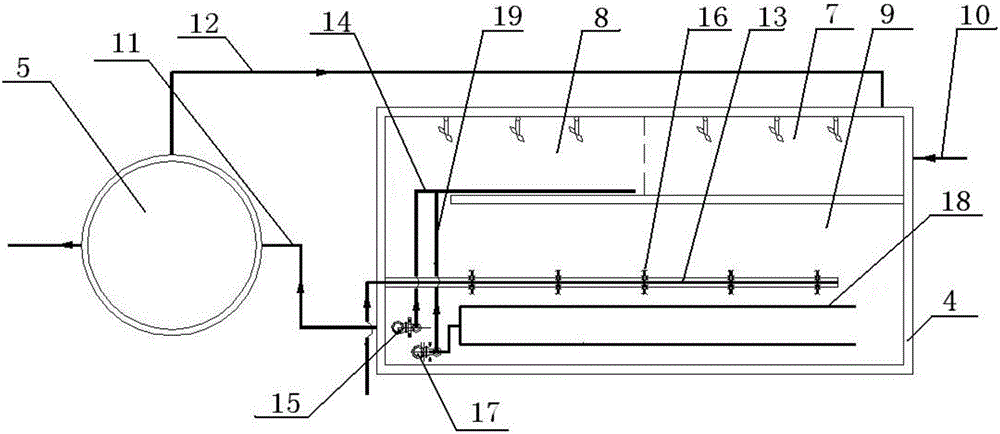

[0020] The device of the present invention adopts grid 1, grit chamber 2, primary sedimentation tank 3, three-stage pond 4, secondary sedimentation pond 5 and contact pond 6, wherein three-stage pond 4 is composed of anaerobic section 7, anoxic section 8, Aerobic section 9, water inlet pipe 10, water outlet pipe 11, sludge return pipe 12, aeration pipe 13, nitrifying liquid return pipe 14 and return pump 15, sludge return pipe 12 is connected between secondary sedimentation tank 5 and anaerobic section 7, the aeration pipe 13 is laid at the bottom of the pool in the aerobic section 9, and the control valve 16 is installed at the standpipe of the aeration pipe 13 at the rear end of the aerobic section 9, and the area at the rear end of the aerobic section 9 forms a sludge sedimentation area , the end of the aerobic section 9 is also equipped with a sludge return pump 17, the inlet of the sludge return pump 17 is connected to a perforated mud collection pipe 18, the perforated mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com