Imitation metal glass and manufacturing method thereof

A manufacturing method, metal imitation technology, applied in the direction of casing/cabinet/drawer parts, etc., can solve the problems of easy scratches, cold hands, strong signal interference, etc., and achieve the effect of delicate appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

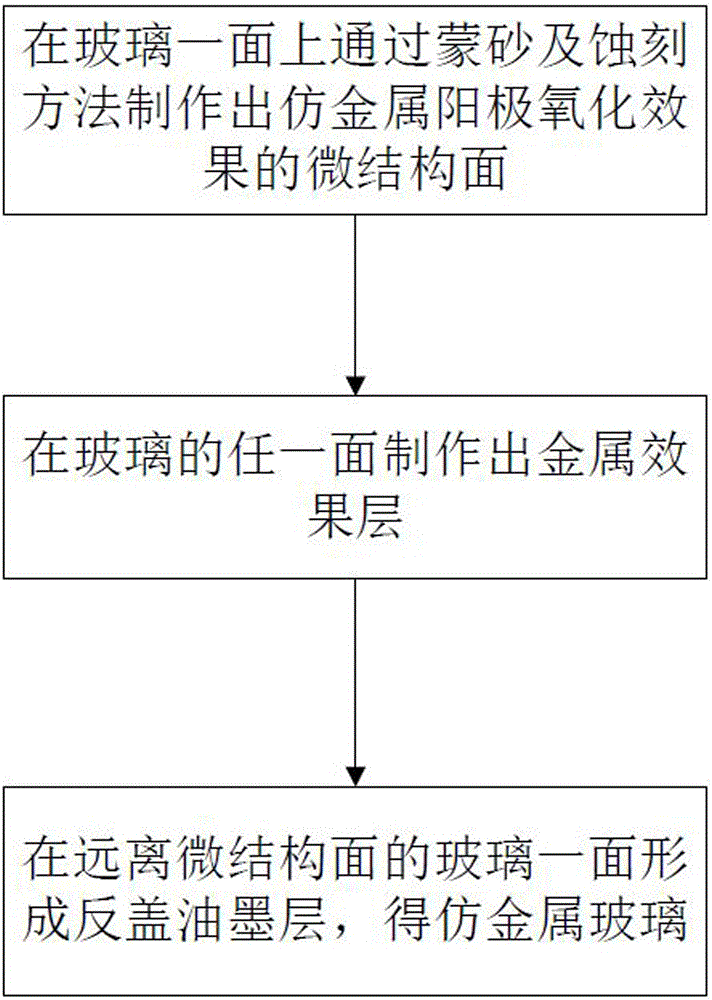

[0037] A method for manufacturing imitation metallic glass, comprising the steps of:

[0038] Step A1, making a microstructure surface imitating metal anodic oxidation effect by frosting and etching on one side of the glass, specifically including the following steps:

[0039] Step A11, cleaning and drying the glass;

[0040] Step A12, provide frosting liquid; apply protective glue on one side of the glass, perform frosting erosion treatment on the other side of the glass, wash and dry, and obtain glass with a frosted surface, and its transmittance is 30%;

[0041] Step A13, apply protective glue on the side of the glass away from the frosted surface, etch the frosted surface with an acid etching solution, remove crystal particles on the glass surface, make it have a certain luster, wash and dry, and obtain a microstructure surface Glass. The glossiness of the glass after etching treatment is about 5, and the roughness is about 1.5 μm.

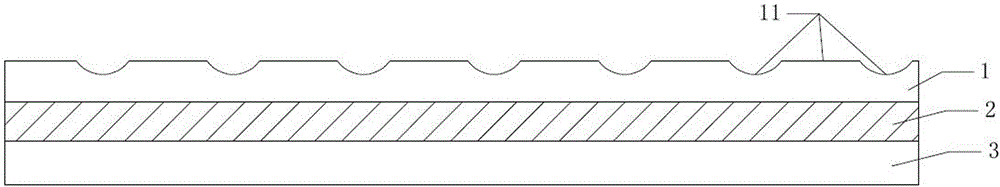

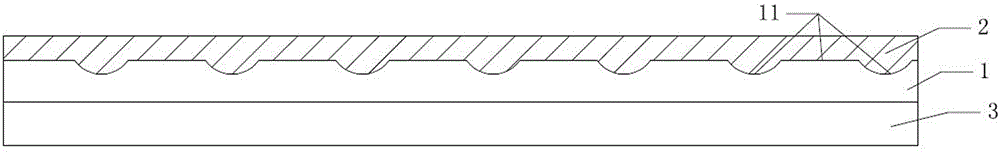

[0042] In step A2, a metal thin film l...

Embodiment 2

[0045] A method for manufacturing imitation metallic glass, comprising the steps of:

[0046] Step B1, making a microstructure surface imitating metal anodic oxidation effect on one side of the glass by frosting and etching, specifically including the following steps:

[0047] Step B11, cleaning and drying the glass;

[0048] Step B12, provide frosting liquid; apply protective glue on one side of the glass, perform frosting erosion treatment on the other side of the glass, wash and dry, and obtain glass with a frosted surface, and its transmittance is 20%;

[0049] Step B13, apply protective glue on the glass side away from the frosted surface, etch the frosted surface with an acid etching solution, remove crystal particles on the glass surface, make it have a certain luster, wash and dry, and obtain a glass with a microstructure surface Glass. The glass gloss after etching treatment is about 60, and the roughness is about 0.08 μm.

[0050] Step B2, using a sputtering proce...

Embodiment 3

[0054] A method for manufacturing imitation metallic glass, comprising the steps of:

[0055] Step C1, making a microstructure surface imitating metal anodic oxidation effect by frosting and etching on one side of the glass, specifically including the following steps:

[0056] Step C11, cleaning and drying the glass;

[0057] Step C12, providing frosting liquid; coating protective glue on one side of the glass, performing frosting erosion treatment on the other side of the glass, cleaning and drying, and obtaining glass with a frosted surface with a transmittance of 10%;

[0058] Step C13, apply protective glue on the side of the glass away from the frosted surface, etch the frosted surface with an acid etching solution, remove crystal particles on the glass surface, make it have a certain luster, wash and dry, and obtain a microstructure surface Glass. After etching, the glossiness of the glass is about 30, and the roughness is about 0.5 μm.

[0059] Step C2, making a meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com