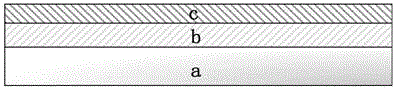

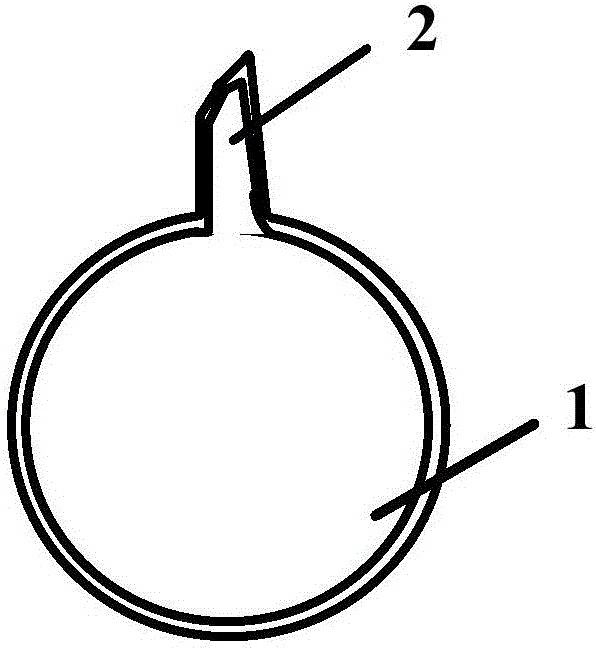

Composite structure film for prolonging relaxation time of magnetometers and plating method of composite structure film

A composite structure and relaxation time technology, applied in the field of measurement, can solve problems such as resonance line width broadening, and achieve the effects of prolonging relaxation time, improving anti-relaxation effect and increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings. But it should not limit the protection scope of the present invention.

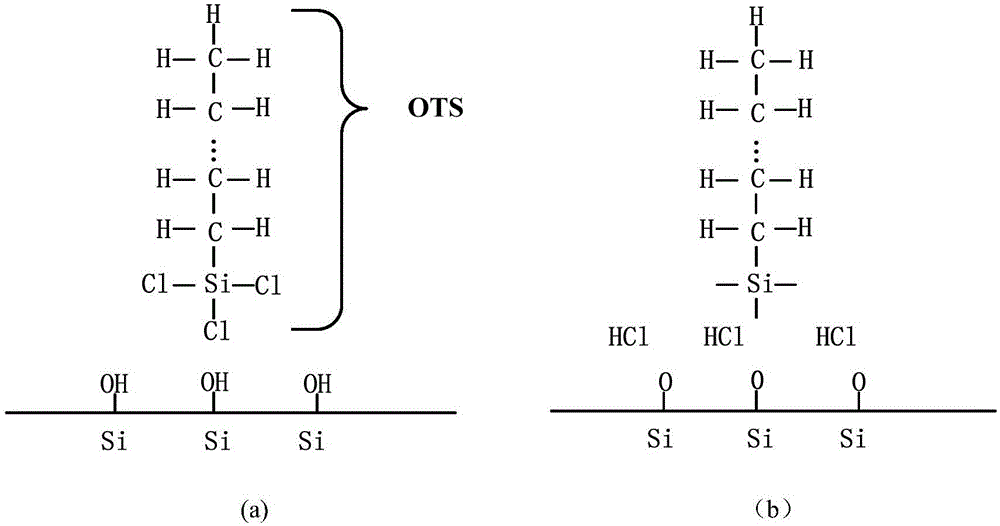

[0032] Below the coating process of the present invention is briefly described, mainly divided into two steps:

[0033] S1 plated OTS film:

[0034] S1.1 Clean the atomic pool. Using the "exhaust method" (use a syringe to connect a Teflon capillary tube to pour the solution into the atomic pool through atmospheric pressure) to make the "piranha" solution (constituted by hydrogen peroxide and concentrated sulfuric acid according to the volume ratio of 3:7, use Add the hydrogen peroxide slowly into the concentrated sulfuric acid with the glue head dropper, and keep stirring) into the atomic pool, the purpose is to remove the organic impurities on the inner wall of the atomic pool, avoid its reaction with OTS, and expose the real glass surface;

[0035] S1.2 After the atomic pool is filled with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com