Method of purifying pneumocandins B0

A technology of extracting liquid and ethanol, applied in the direction of peptides, etc., can solve the problems of large amount of solvent, time-consuming, environmental pollution, etc., and achieve the effects of being conducive to industrialized large-scale production, reducing production costs, and simplifying process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

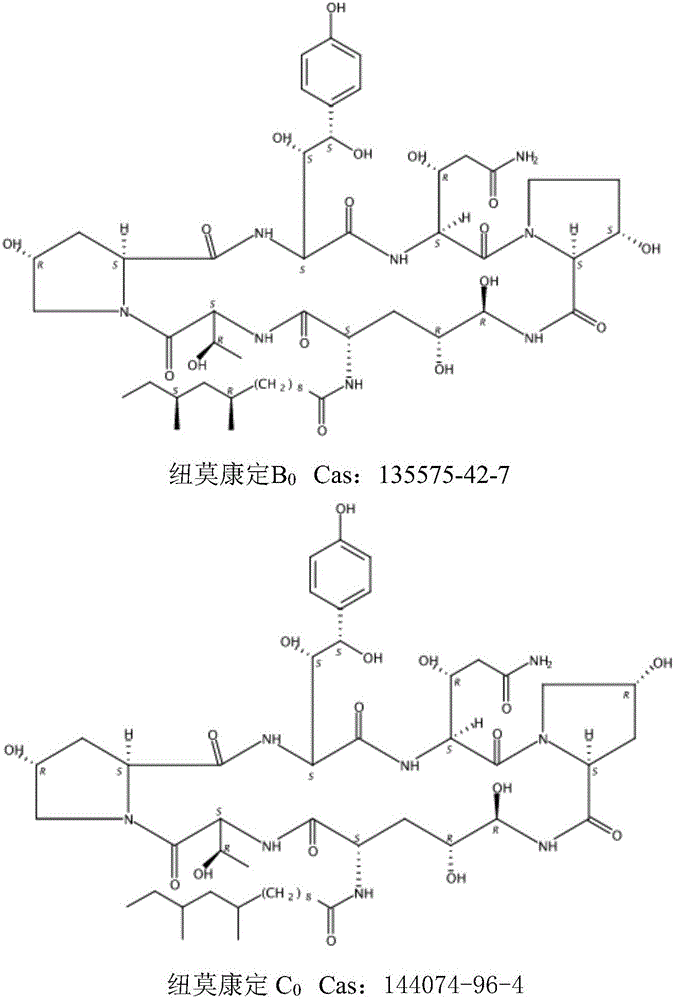

Image

Examples

Embodiment 1

[0028] The 11 tons of fermented liquid are first transferred to the acidification tank, the pH value of the fermented liquid is adjusted to 3.0 with oxalic acid, and plate and frame filter press. To obtain 1200 kg of fungus residue, add 6 tons of 75% ethanol solution, stir for 6 hours, and plate and frame filter again to obtain 6 tons of extract.

[0029] Transfer the extract to a 1000L enamel kettle again, control the temperature ≤ 50°C, and vacuum ≤ -0.07MPa to concentrate in vacuo. During the concentration process, observe that the liquid becomes turbid, then sample and centrifuge, and send the clear liquid for inspection. Neomercontin B 0 When the content is 48mg / L, the concentration is stopped to obtain 50kg of the concentrated extract mixture; 200kg of diatomite with a specification of 100 mesh is added to the concentrated extract mixture to fully absorb, wrap the crystals, add 250kg of deionized water to stir, and centrifuge to obtain Mokandine B 0 260kg of centrifuge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com