Preparation method of nanocellulose/fluorine-containing polyacrylate composite emulsion

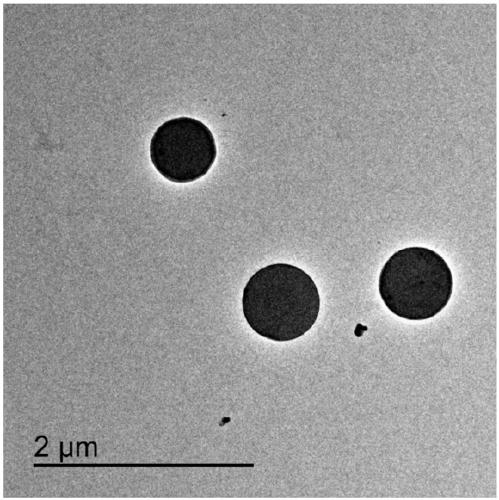

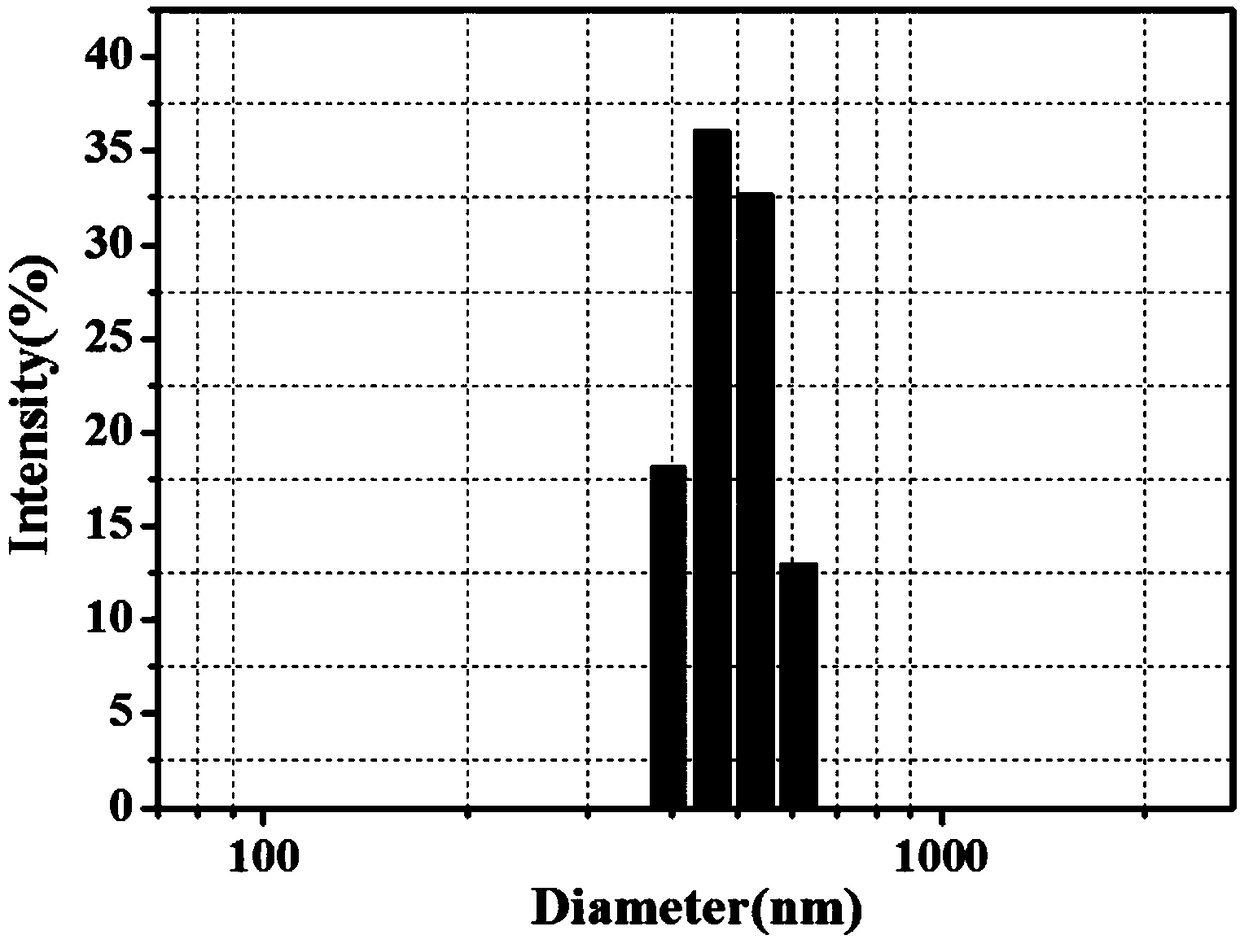

A technology of nanocellulose and polyacrylate, applied in the field of compound emulsion preparation, to achieve good stability, high Young's modulus, and small particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Get amphiphilic block copolymer modified nanocellulose (MCNC) and grind it into powder to obtain amphiphilic block copolymer modified nanocellulose powder;

[0052] Weigh the amphiphilic block copolymer modified nanocellulose powder and deionized water at a mass ratio of 1:1000; weigh the amphiphilic block copolymer modified nanocellulose powder and deionized water mixed with water to form a mixed solution; the obtained mixed solution was dispersed in an ultrasonic cell pulverizer with a power of 20%, to obtain a light yellow modified nanocellulose dispersion;

[0053] Mix the modified nanocellulose dispersion with the mixed monomers at a mass ratio of 9:1 to form a mixture; place the mixture in an ultrasonic cell pulverizer with a power of 20% for mixing and emulsification to obtain a stable Pickering emulsion;

[0054] At room temperature, add the Pickering emulsion into a three-neck flask equipped with mechanical stirring, reflux condenser, and airway; place the thre...

Embodiment 2

[0056] Get amphiphilic block copolymer modified nanocellulose (MCNC) and grind it into powder to obtain amphiphilic block copolymer modified nanocellulose powder;

[0057] Weigh the amphiphilic block copolymer modified nanocellulose powder and deionized water respectively according to the mass ratio of 1:500; the weighed amphiphilic block copolymer modified nanocellulose powder and deionized water mixed with water to form a mixed solution; the obtained mixed solution was dispersed in an ultrasonic cell pulverizer with a power of 30% to obtain a light yellow modified nanocellulose dispersion;

[0058] Mix the modified nanocellulose dispersion with the mixed monomers at a mass ratio of 7:3 to form a mixture; place the mixture in an ultrasonic cell pulverizer with a power of 30% for mixing and emulsification to obtain a stable Pickering emulsion;

[0059] At room temperature, add the Pickering emulsion to a three-necked flask equipped with mechanical stirring, reflux condenser, a...

Embodiment 3

[0061] Get amphiphilic block copolymer modified nanocellulose (MCNC) and grind it into powder to obtain amphiphilic block copolymer modified nanocellulose powder;

[0062] Weigh the amphiphilic block copolymer modified nano-cellulose powder and deionized water at a mass ratio of 1:100; weigh the amphiphilic block copolymer-modified nano-cellulose powder and deionized water mixed with water to form a mixed solution; the obtained mixed solution was dispersed in an ultrasonic cell pulverizer with a power of 50%, to obtain a light yellow modified nanocellulose dispersion;

[0063] Mix the modified nanocellulose dispersion with the mixed monomer according to the mass ratio of 8.5:1.5 to form a mixture; place the mixture in an ultrasonic cell pulverizer with a power of 50% for mixing and emulsification to obtain a stable Pickering emulsion;

[0064] At room temperature, add the Pickering emulsion to a three-necked flask equipped with mechanical stirring, reflux condenser, and air gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com