Low-delayed-coagulation and high-dispersity polycarboxylic acid super plasticizer and preparation method and application thereof

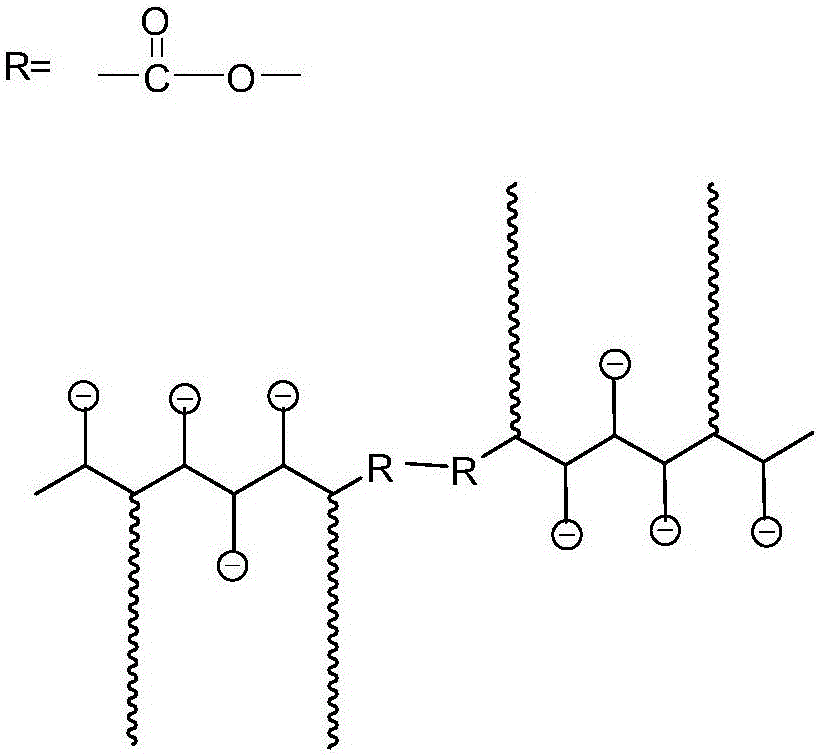

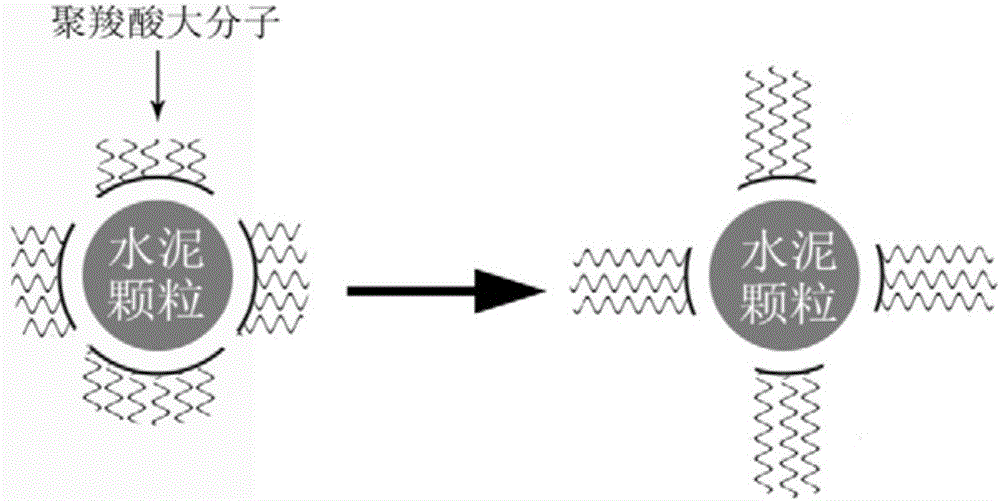

A superplasticizer and high-dispersion technology, applied in the field of superplasticizers, can solve the problems of low cost performance, high viscosity, low conversion rate of esterification, etc., to facilitate the development of early strength, enhance the steric hindrance effect, The effect of accelerated hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

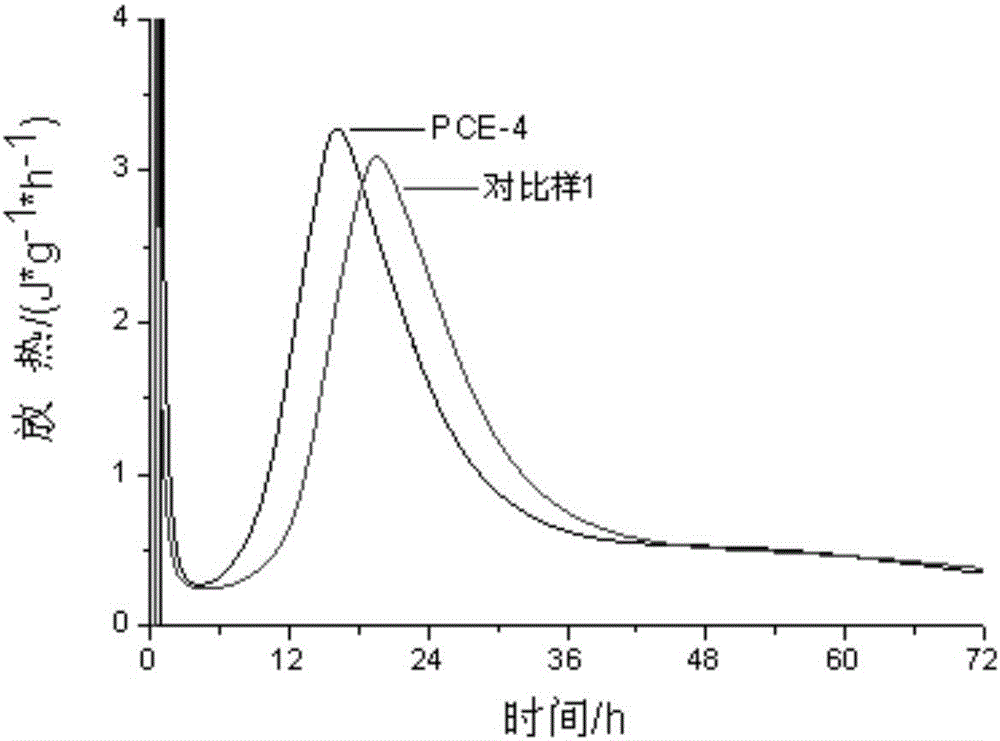

Examples

Embodiment 1

[0046] Add 77.8g of water and 71.8g of A-1 in sequence to a 250mL four-necked flask equipped with a stirrer, thermometer, nitrogen inlet tube, and dropping device, and raise the temperature to 85°C under nitrogen protection. After stirring evenly, add 1.6g of C- 1. Stir for another 10 minutes, add 7.5g B-1, 0.01g D-1, and 0.44g E-1 aqueous solutions dropwise, the dropping time is 2h and 2.5h respectively, after the dropping is completed, keep warm for 1.5h, and the reaction is over Afterwards, the temperature was slowly lowered to 40° C., and the pH value of the obtained product was adjusted to about 5 with a sodium hydroxide solution having a mass concentration of 30%. Cool to normal temperature, dilute with water to obtain a low-retarding high-dispersion polycarboxylate superplasticizer with a mass concentration of 40%, marked as PCE-1.

Embodiment 2

[0048] Add 79.1g of water and 70.7g of A-2 in sequence to a 250mL four-neck flask equipped with a stirrer, thermometer, nitrogen gas introduction tube, and dropping device, raise the temperature to 65°C under nitrogen protection, stir well, and then add 0.3g of C- 1. Stir for another 10 minutes, add 7.5g B-1, 1.2g B-2 and 0.01g D-1, 0.52g E-1 aqueous solutions dropwise, the dropping time is 2.5h and 3h respectively, keep warm after the dropping is completed After reacting for 1.5 hours, after the reaction was completed, the temperature was slowly lowered to 40° C., and the obtained product was adjusted to a pH value of about 5 with a sodium hydroxide solution having a mass concentration of 30%. Cool to normal temperature, dilute with water to obtain a low-retarding high-dispersion polycarboxylate superplasticizer with a mass concentration of 40%, marked as PCE-2.

Embodiment 3

[0050] Add 76.8g of water and 72.8g of A-3 in sequence to a 250mL four-necked flask equipped with a stirrer, thermometer, nitrogen inlet tube, and dropping device, and raise the temperature to 45°C under the protection of nitrogen. After stirring evenly, add 0.68g of C- 2. Stir for another 10 minutes, add 6.5g B-1, 0.12g D-1, and 0.36g E-1 aqueous solution dropwise, the dropwise addition time is 3h and 3.5h respectively, keep warm for 1h after the dropwise addition, after the reaction , slowly lower the temperature to 40° C., and adjust the pH value of the obtained product to about 5 with a sodium hydroxide solution having a mass concentration of 30%. Cool to normal temperature, dilute with water to obtain a low-retarding high-dispersion polycarboxylate superplasticizer with a mass concentration of 40%, marked as PCE-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com