Synthesis method for producing hydroxy silicone oil from waste silicone rubber

A technology of hydroxy silicone oil and synthesis method, applied in recycling technology, plastic recycling and other directions, can solve problems such as waste of resources and aggravate environmental burden, and achieve the effect of avoiding pollution and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

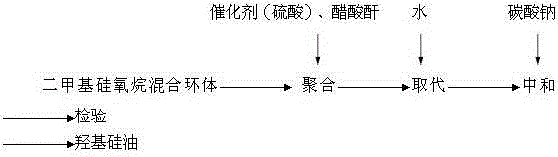

Image

Examples

Embodiment 1

[0011] The present invention is carried out according to the following process steps: extract the dimethylsiloxane mixed ring body in the waste silicone rubber into the reaction kettle, raise the temperature of the crude oil to 93°C, add acetic anhydride, use sulfuric acid as a catalyst, Polymerize at low temperature for 4 hours; then raise the temperature to 155°C, remove low molecular weight, cool to 70°C, then add water and sodium carbonate for neutralization reaction to neutrality, and obtain hydroxyl silicone oil after cooling.

Embodiment 2

[0013] The present invention is carried out according to the following process steps: extract the dimethylsiloxane mixed ring body in the waste silicone rubber into the reaction kettle, raise the temperature of the crude oil to 90°C, add acetic anhydride, use sulfuric acid as a catalyst, Polymerize at low temperature for 3.5 hours; then raise the temperature to 160°C to remove low molecular weight, cool to 60°C, then add water and sodium carbonate for neutralization reaction to neutrality, and obtain hydroxyl silicone oil after cooling.

Embodiment 3

[0015] The present invention is carried out according to the following process steps: extract the dimethylsiloxane mixed ring body in the waste silicone rubber into the reaction kettle, raise the temperature of the crude oil to 100°C, add acetic anhydride, use sulfuric acid as a catalyst, Polymerize at low temperature for 3.5-5 hours; then raise the temperature to 150°C to remove low molecular weight, cool to 70°C, then add water and sodium carbonate to neutralize the reaction to neutrality, and obtain hydroxyl silicone oil after cooling.

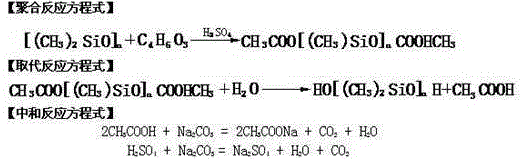

[0016] Reaction equation of the present invention is:

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com