Polyethylene glycol hydrogel material and preparing method thereof

A polyethylene glycol and hydrogel technology, which is applied in the fields of biochemical equipment and methods, analytical materials, chemical instruments and methods, etc., can solve the problems of few methods for adjusting the mechanical properties of hydrogels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a preparation method of a polyethylene glycol hydrogel material. After the mixed raw materials are gelled in the presence of a catalyst, the unreacted raw materials are washed and removed, and then the corresponding hydrogel is obtained through hydration. The method comprises the step of reacting the raw material to form a gel under the condition of the presence of the catalyst; the raw material is obtained by uniformly mixing polyethylene glycol, polyhydroxy compound and divinyl sulfone.

[0023] In a specific embodiment, the polyethylene glycol is hydroxyl-terminated polyethylene glycol, without further derivatization, having the structure of general formula i, and the degree of polymerization n≥3. Polyethylene glycol with a polymerization degree of 6≤n≤150 is preferred.

[0024]

[0025] On the other hand, the polyhydroxy compound is selected from glycerol, butylene glycol, polyvinyl alcohol, sugar, multi-armed polyethylene glycol, cellulose...

Embodiment 1

[0033] Preparation of polyethylene glycol hydrogels

[0034] The polyethylene glycol hydrogel is prepared by using hexapolyethylene glycol (n=6) as the polyethylene glycol raw material and glycerol as the polyhydroxy compound raw material. Weigh 0.56g hexapolyethylene glycol (2mmol), 0.96g divinyl sulfone (8mmol), 0.37g glycerol (4mmol), add 0.098g 4-dimethylaminopyridine (0.8mmol, 0.1eq.) and mix well, Stand at room temperature for 12h. The obtained gel was soaked and washed 3 times with ethanol, and washed 3 times with water to obtain a colorless transparent hydrogel material, such as figure 1 shown.

Embodiment 2

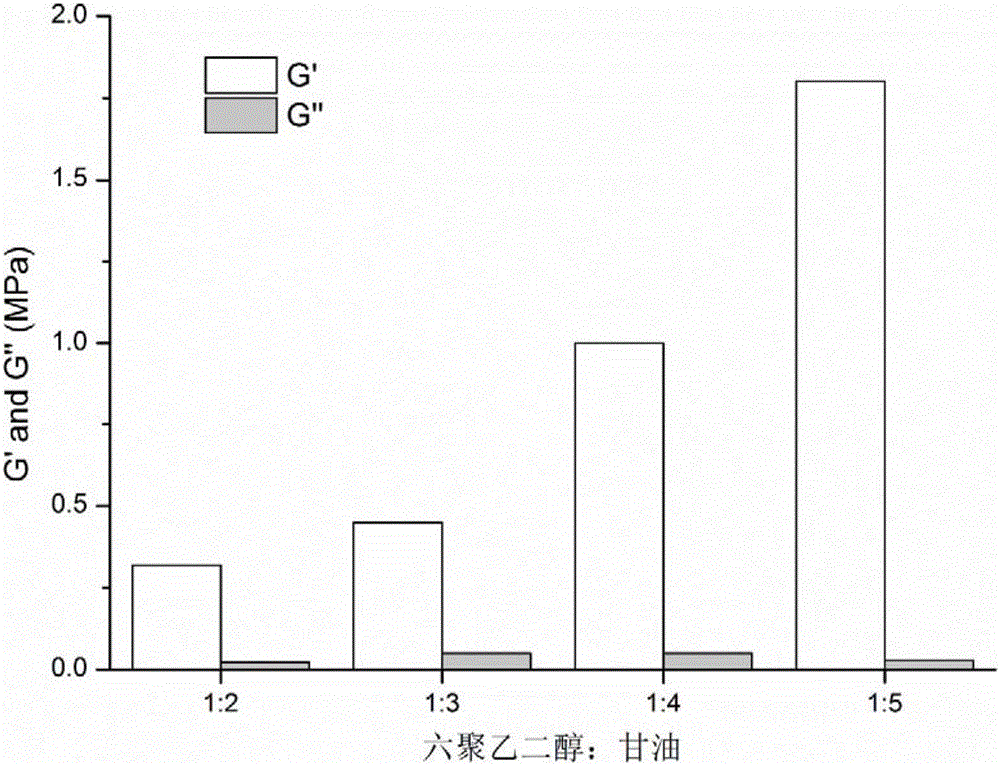

[0036] Modulation of Mechanical Properties of Polyethylene Glycol Hydrogels by Polyol Ratio

[0037] Polyethylene glycol hydrogel was prepared by using hexapolyethylene glycol as polyethylene glycol raw material and glycerin as polyol raw material. Weigh 0.56g hexapolyethylene glycol (2mmol), insert 4, 6, 8, 10mmol glycerin respectively, and add divinyl sulfone and 0.1eq 4-dimethylaminopyridine of the amount of corresponding substances, mix and place On the flat plate rheometer, the mechanical properties of the hydrogel prepared under different glycerin ratio conditions were measured, and the results were as follows: figure 2 shown. As the proportion of glycerol increases, the storage modulus of the hydrogel increases; while the loss modulus remains almost unchanged, indicating that the toughness of the hydrogel increases with the proportion of glycerol increasing. This result indicates that the regulation of the mechanical properties of hydrogels can be achieved by adjusti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com