Ultrahigh-toughness flame-retardant mineral powder filling PC (polycarbonate) material and preparation method thereof

A technology of polycarbonate and ultra-high toughness, which is applied in the field of ultra-high toughness flame-retardant mineral powder filled polycarbonate material and its preparation, which can solve the problems of damaged molds and serious floating fibers, etc., and achieve the effect of reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments.

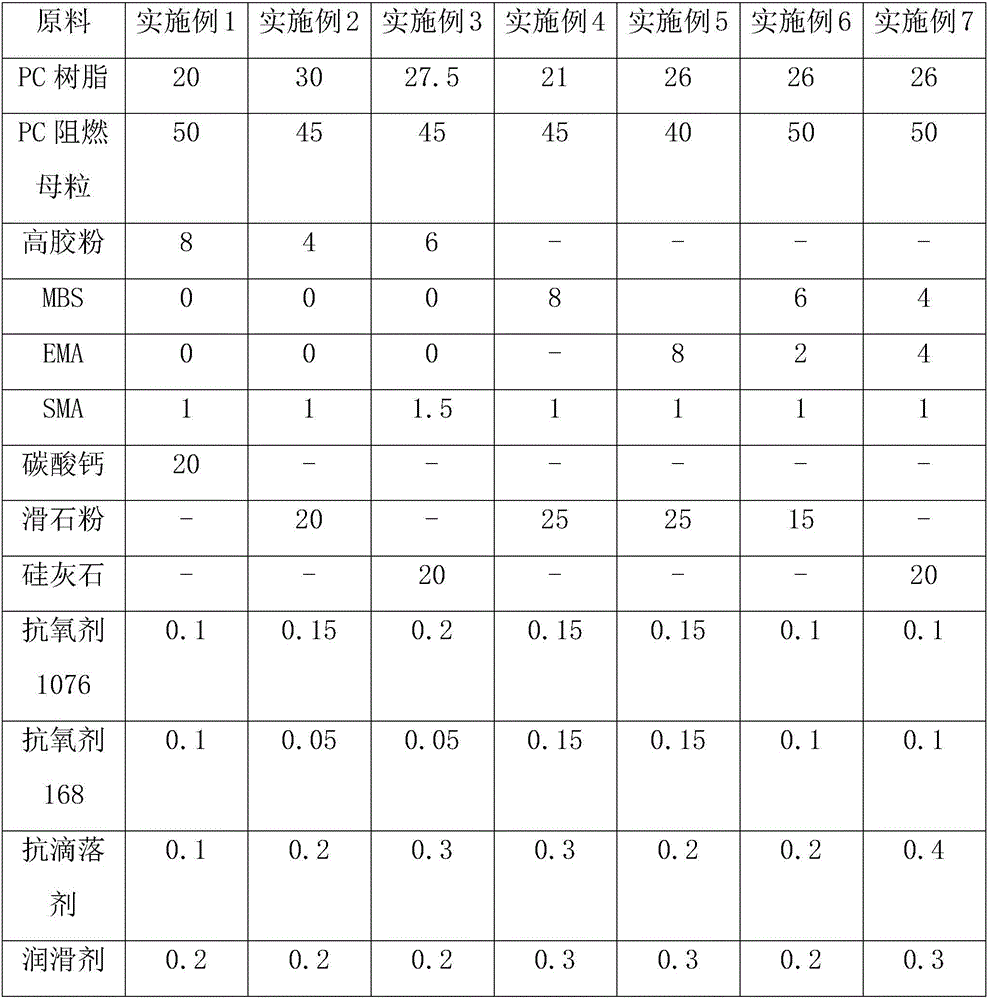

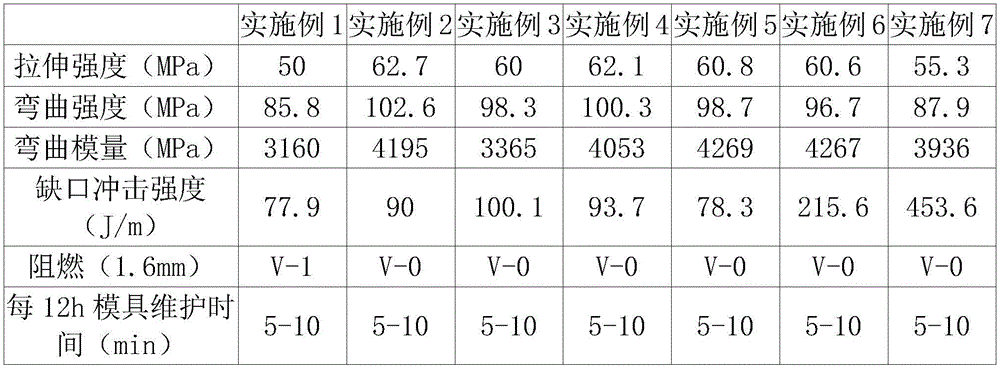

[0024] Embodiment 1-7 provides a kind of preparation method of the present invention a kind of ultra-high toughness flame-retardant mineral powder filled polycarbonate material, wherein, compatibilizer is styrene-maleic anhydride copolymer SMA, flame retardant is bisphenol A Bis(diphenyl phosphate), the antioxidants are 1076 and 168, the anti-dripping agent is a modified polytetrafluoroethylene anti-dripping agent, and the lubricant is ethylene bisstearamide.

[0025] Embodiments 1-7 are all based on the raw material components (units are parts by weight) in Table 1, and prepare ultra-high toughness flame-retardant mineral powder-filled polycarbonate materials according to the following steps:

[0026] (1) Take each component according to the mass proportion;

[0027] (2) Preparation of PC flame retardant masterbatch: mix PC resin and flame retardant at a weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com