Water-in-water multicolor paint preparation method capable of high-speed slicing and granulation and paint prepared by method

A technology of colorful coatings and water-in-water, which is applied in the field of functional coatings for architectural decoration. It can solve the problems of affecting production progress, low spraying efficiency, and low mechanical strength, and achieve the goals of saving construction costs, improving work efficiency, and excellent mechanical strength and toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

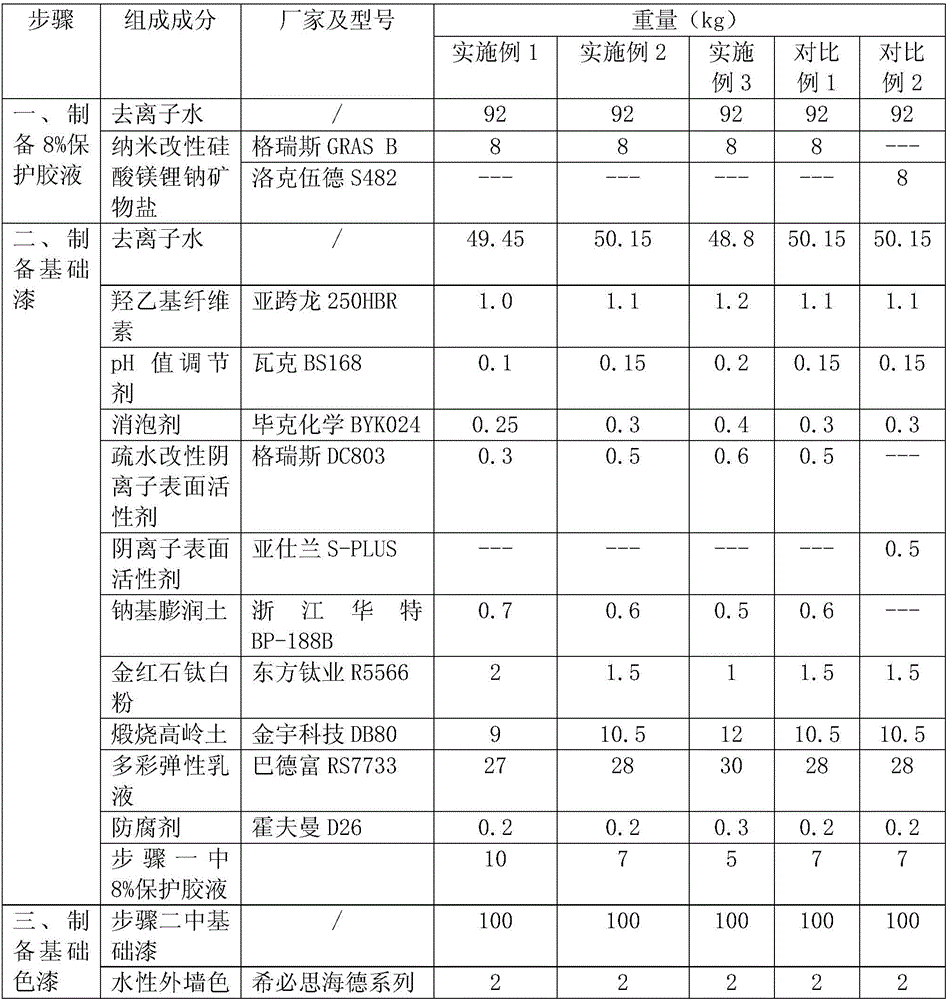

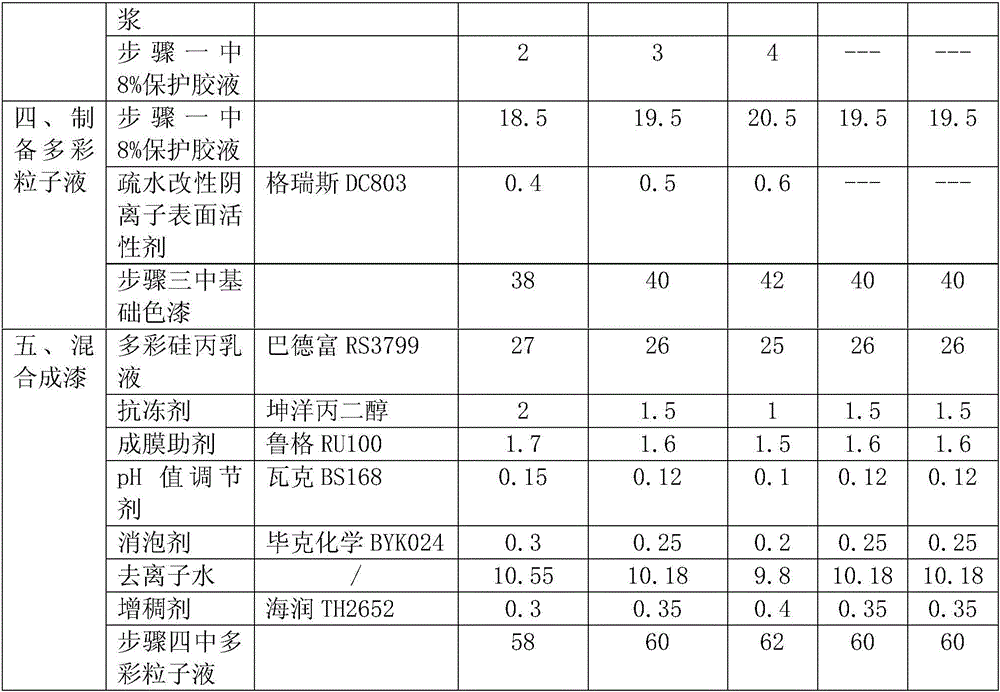

[0055] As shown in Table 1, the weight required for each step in Example 1 takes each component, and the preparation method follows the steps below:

[0056] Step 1: Prepare 8% protective glue

[0057] Add 92kg of deionized water in the pre-dissolved cylinder, start stirring, then slowly add 8kg of nano-modified magnesium lithium silicate sodium mineral salt of GRAS B under stirring, and then rotate at 600 rpm Disperse at low temperature for 60 minutes until the dispersion is complete, and let it stand for 24 hours for later use to obtain 8% protective glue.

[0058] Step 2: Prepare the base paint

[0059] Add 49.5 kg of deionized water into the production tank, add 1.0 kg of hydroxyethyl cellulose of the type 250HBR of Aqualon Company under stirring at 400 rpm, and continue to disperse for 30 minutes until the dispersion is complete. Add successively 0.1kg of pH regulator BS168 from WACKER, 0.25kg of BYK024 defoamer from BYK, 0.3kg of hydrophobically modified anionic surfac...

Embodiment 2

[0067] As shown in Table 1, the weight required for each step in Example 2 takes each component, and the preparation method follows the steps below:

[0068] Step 1: Prepare 8% protective glue

[0069] Add 92kg of deionized water in the pre-dissolved cylinder, start stirring, then slowly add 8kg of nano-modified magnesium silicate lithium sodium mineral salts of GRAS B under stirring, and then at 300 rpm Disperse at low temperature for 70 minutes until the dispersion is complete, and let it stand for 24 hours for later use to obtain 8% protective glue.

[0070] Step 2: Prepare the base paint

[0071] Add 50.15 kg of deionized water into the production tank, and add 1.1 kg of hydroxyethyl cellulose of the type 250HBR of Aqualon Company under stirring at 300 rpm, and continue to disperse for 40 minutes until the dispersion is complete. Add 0.15kg of pH regulator BS168 from WACKER, 0.3kg BYK024 defoamer from BYK, 0.5kg DC803 hydrophobically modified anionic surfactant from Fosh...

Embodiment 3

[0079] As shown in Table 1, the weight required for each step in Example 3 takes each component, and the preparation method follows the steps below:

[0080] Step 1: Prepare 8% protective glue

[0081] Add 92kg of deionized water in the pre-dissolved cylinder, start stirring, then slowly add 8kg of nano-modified magnesium silicate lithium sodium mineral salt of GRAS B under stirring, and then at 500 rpm Disperse at low temperature for 60 minutes until the dispersion is complete, and let it stand for 24 hours for later use to obtain 8% protective glue.

[0082] Step 2: Prepare the base paint

[0083]Add 48.8 kg of deionized water into the production tank, add 1.2 kg of hydroxyethyl cellulose of the type 250HBR of Aqualon Company under stirring at 300 rpm, and continue to disperse for 40 minutes until the dispersion is complete. Add 0.2kg of pH regulator BS168 from WACKER, 0.4kg of BYK024 defoamer from BYK, 0.6kg of DC803 hydrophobically modified anionic surfactant from Foshan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com