Patents

Literature

39results about How to "No blurring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

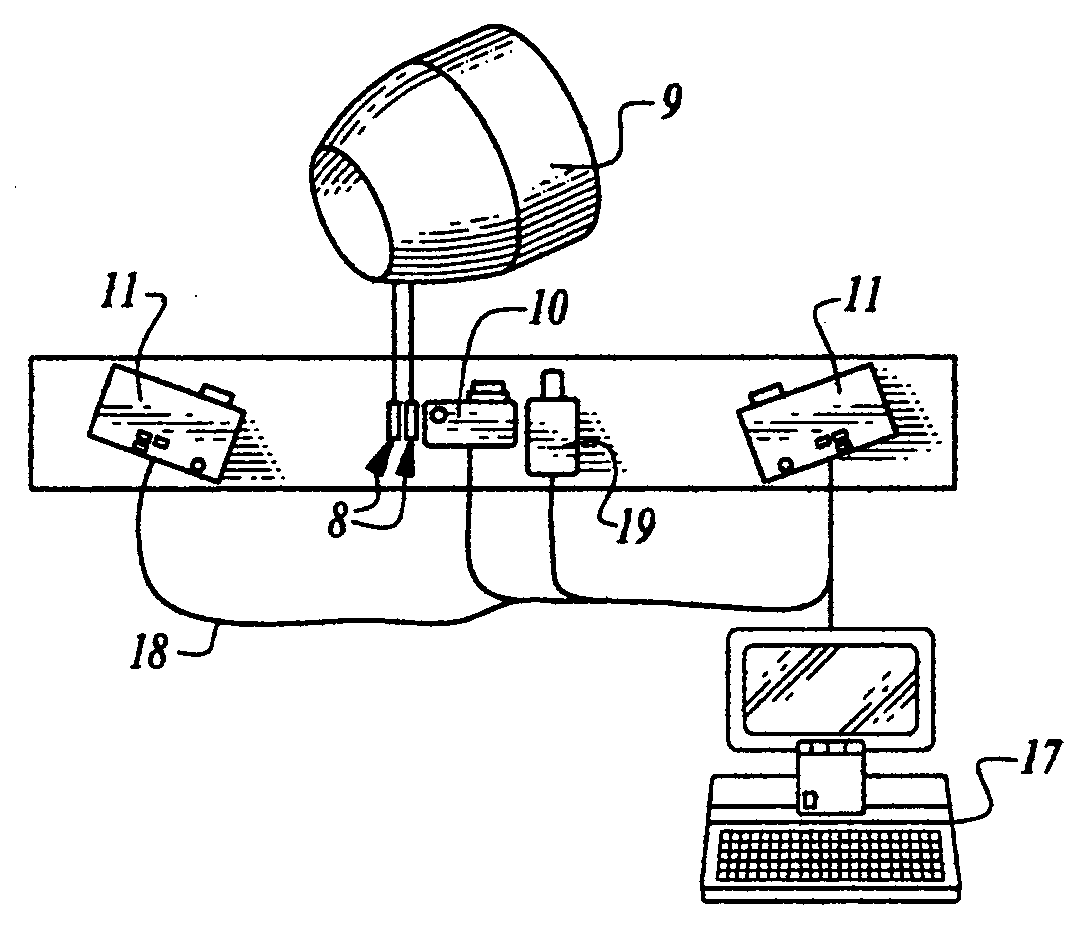

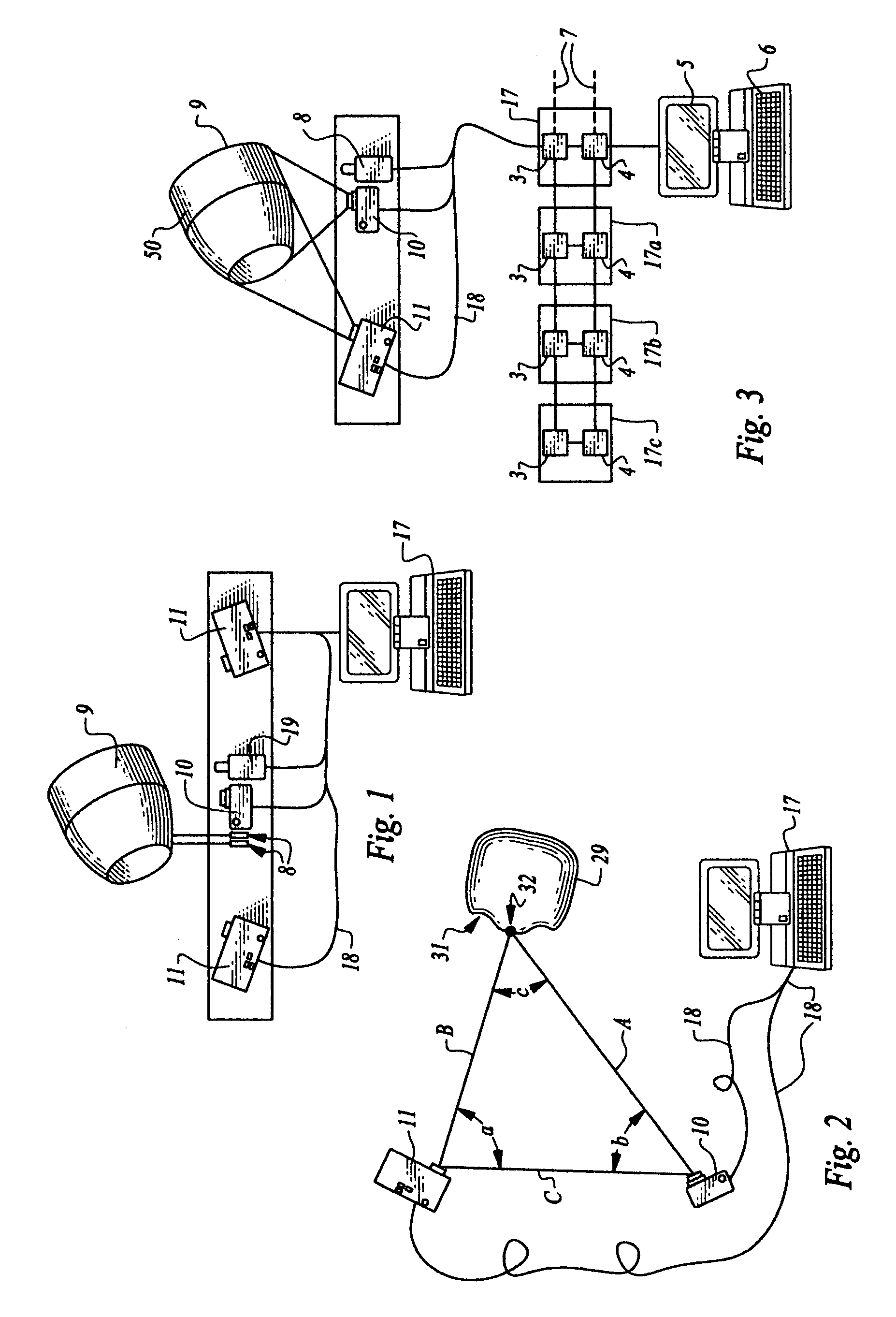

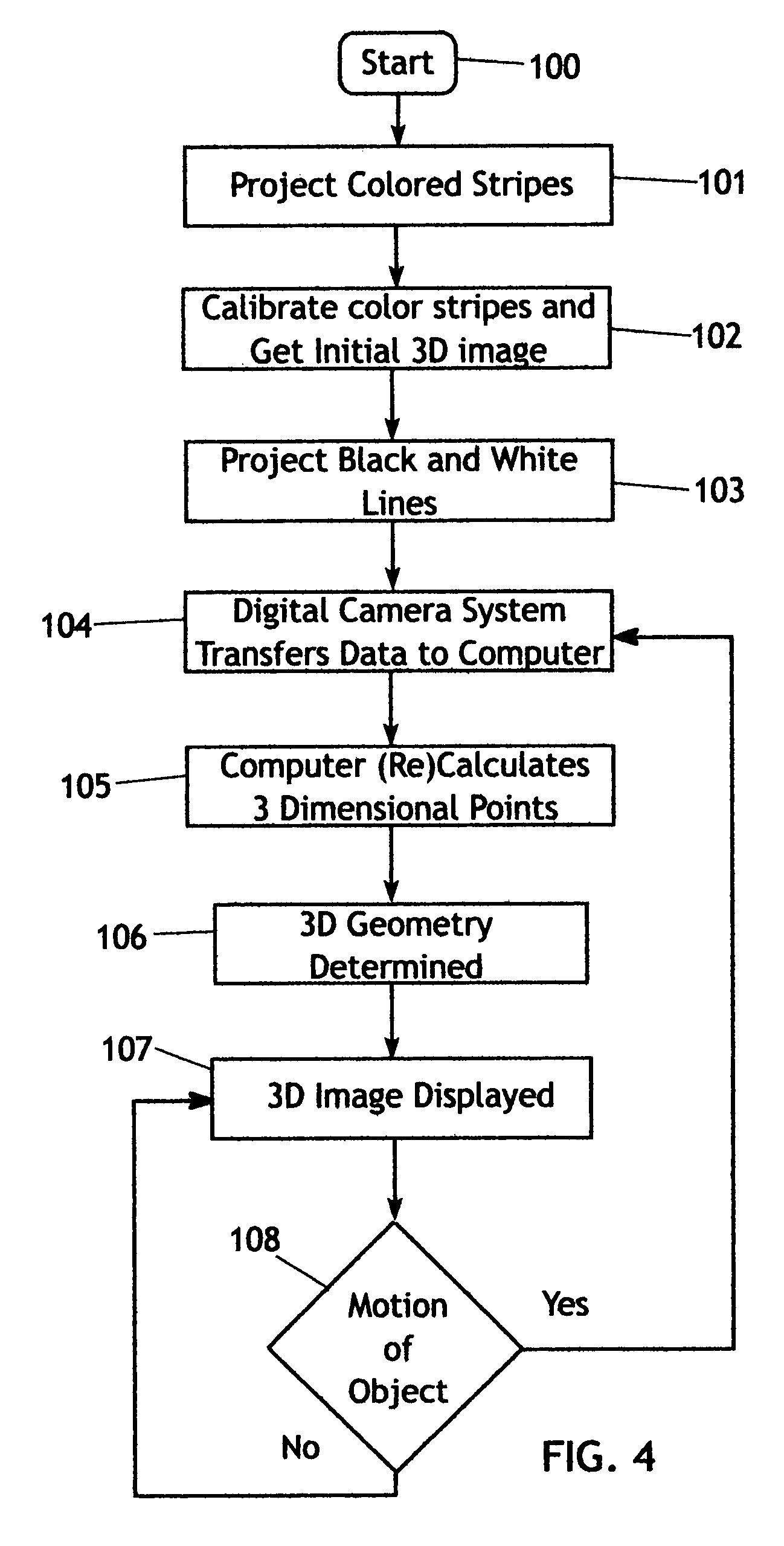

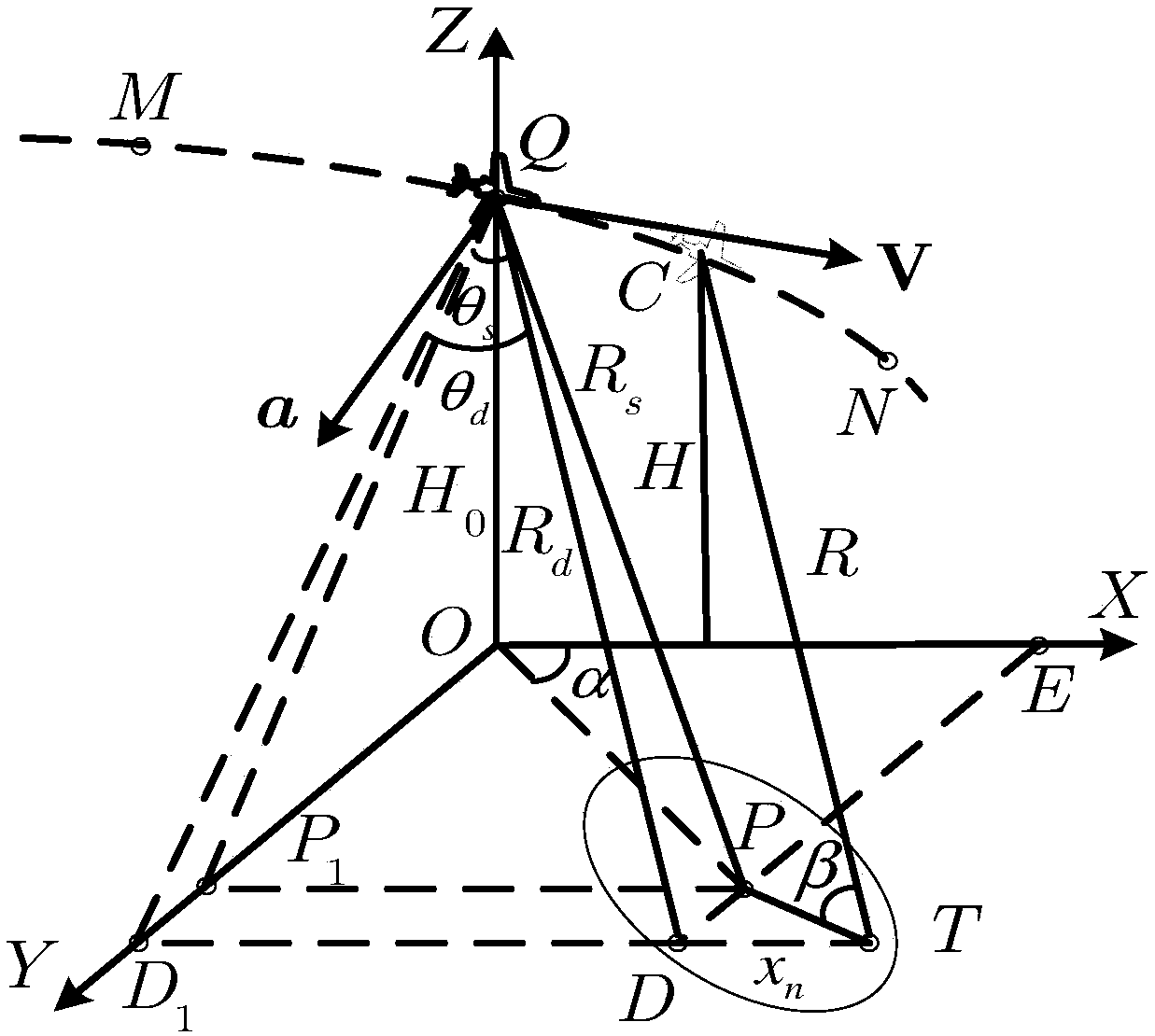

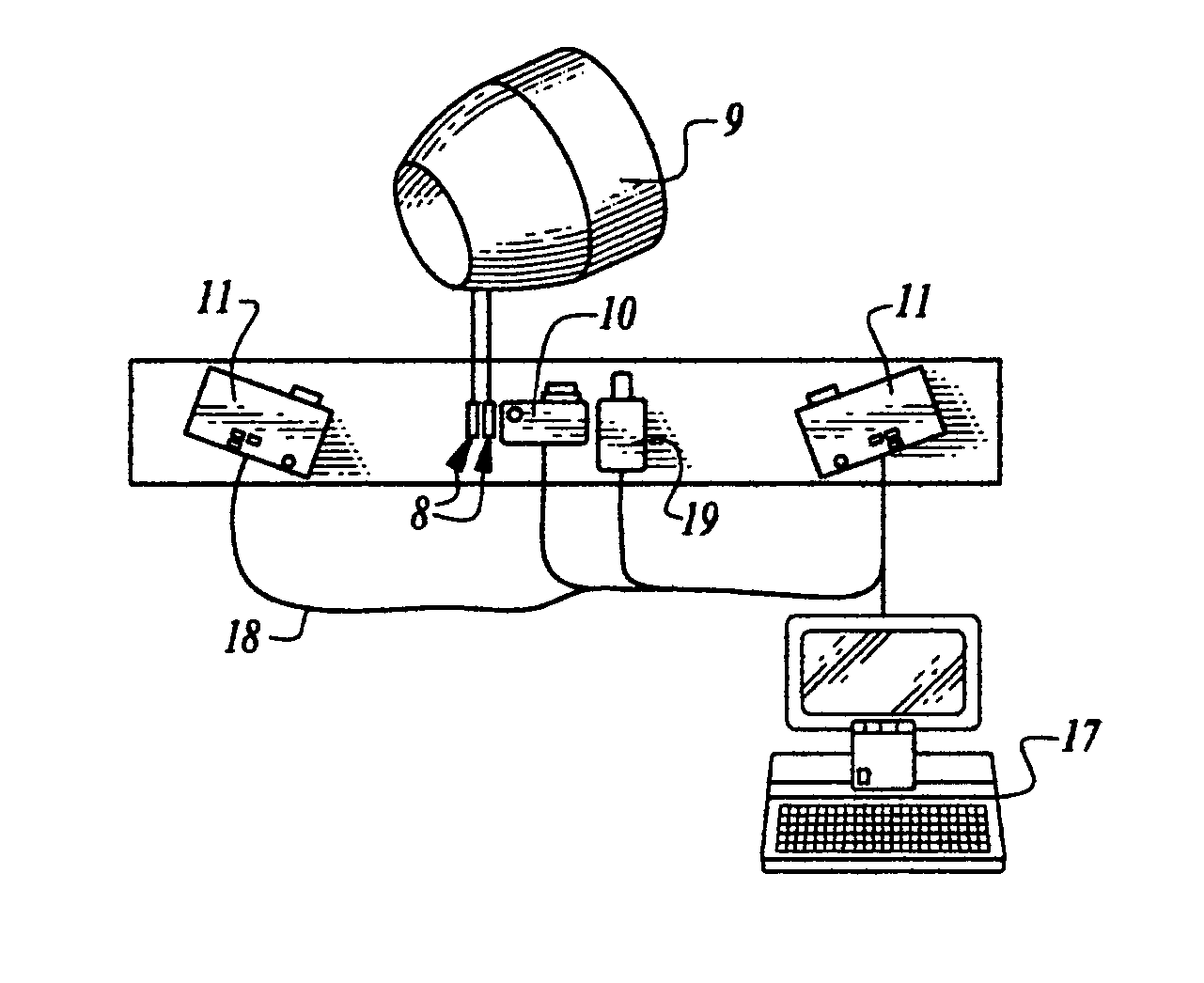

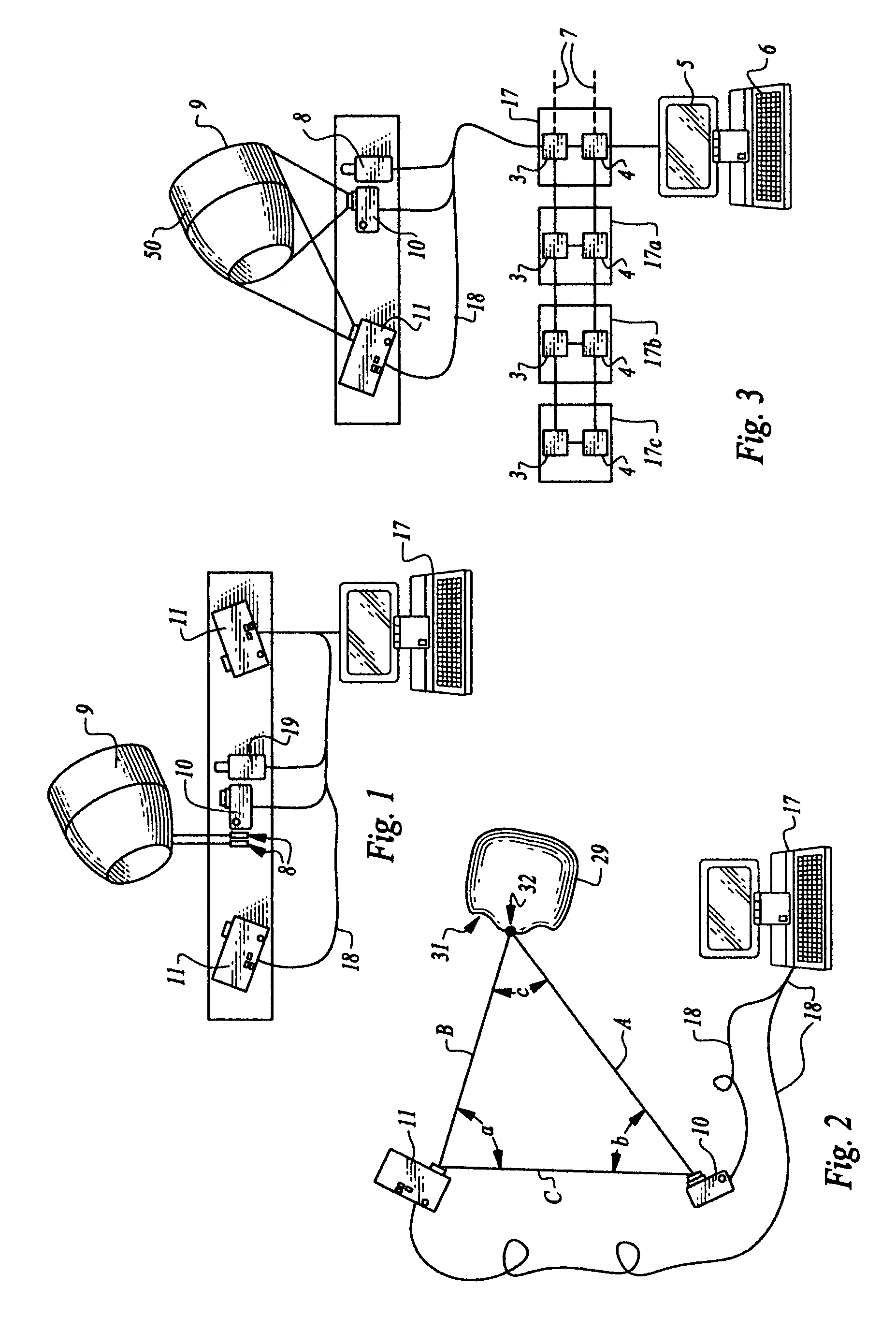

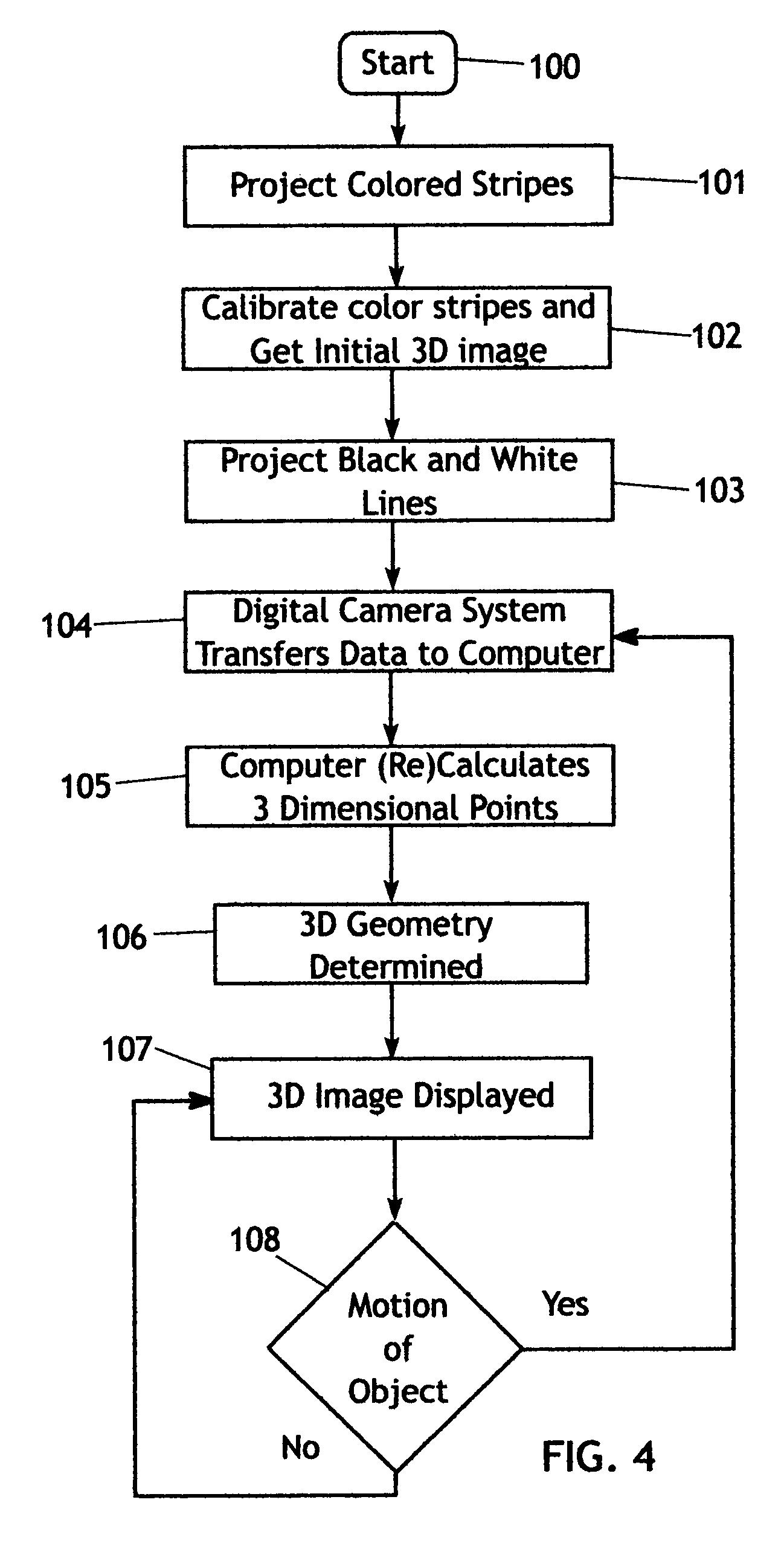

Method and apparatus for dynamic space-time imaging system

InactiveUS20070299338A1Fast enough to eliminateNo blurringImage analysisMaterial analysis by optical meansSingle flashJet aeroplane

A method for creating a 3 D map of the surface contours of an object includes projecting a variety of patterns onto the object, and imaging the patterns as they fall on the object to encode the topographic features of the object. In one embodiment a three dimensional image is taken in a single flash to avoid blurring due to motion of the object. Thereafter a secondary pattern is projected to detect changes in the initial image. The images are processed in a computer program in a manner such that a complete 3D map of the surface of the object is obtained in digital form. Reiteration of the method can detect motional variation such as a breathing human, flexure of a complex mechanical structure, or a stress-strain testing of an airplane, vehicle, beam, bridge, or other structure.

Owner:4D IMAGING +1

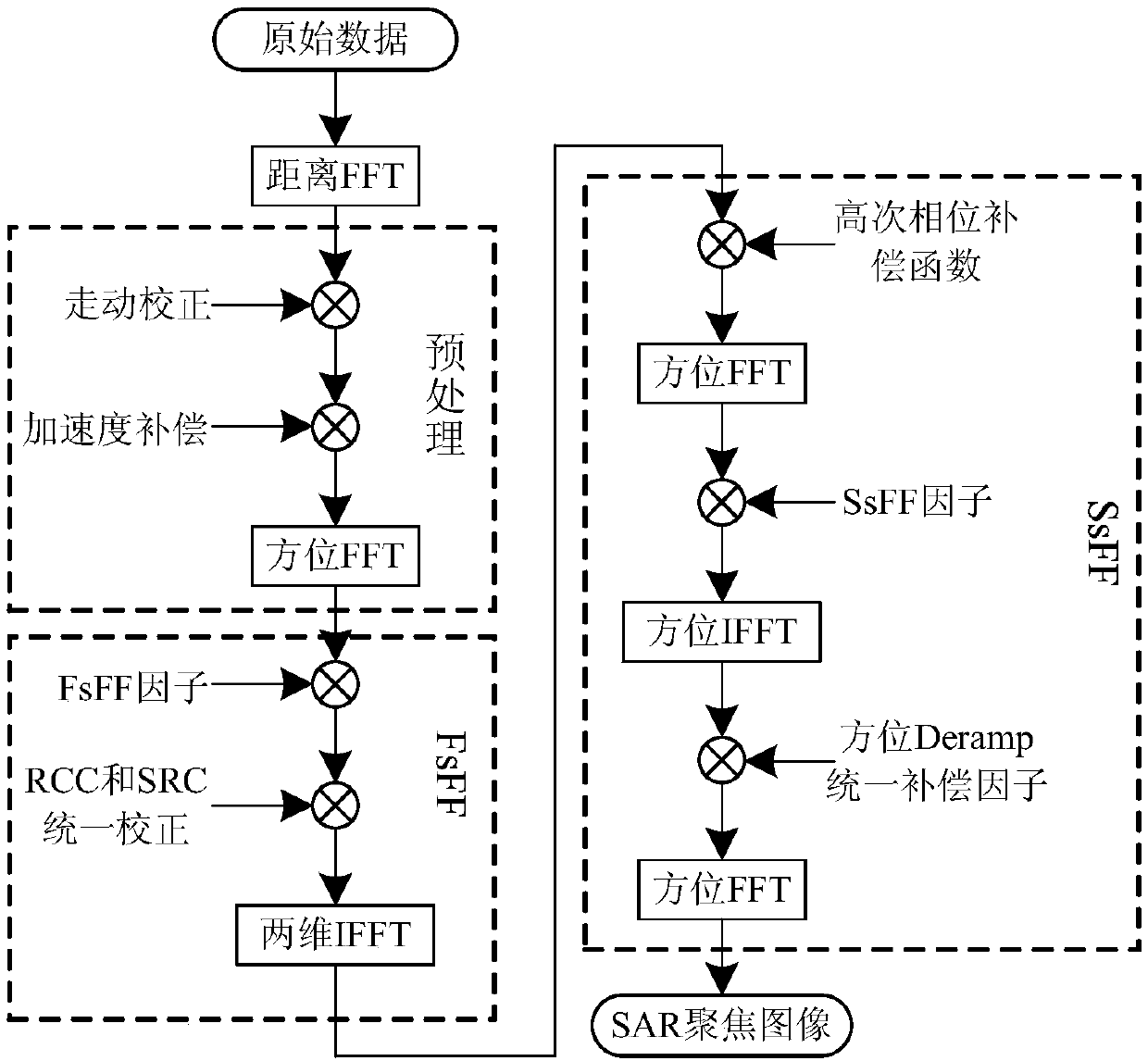

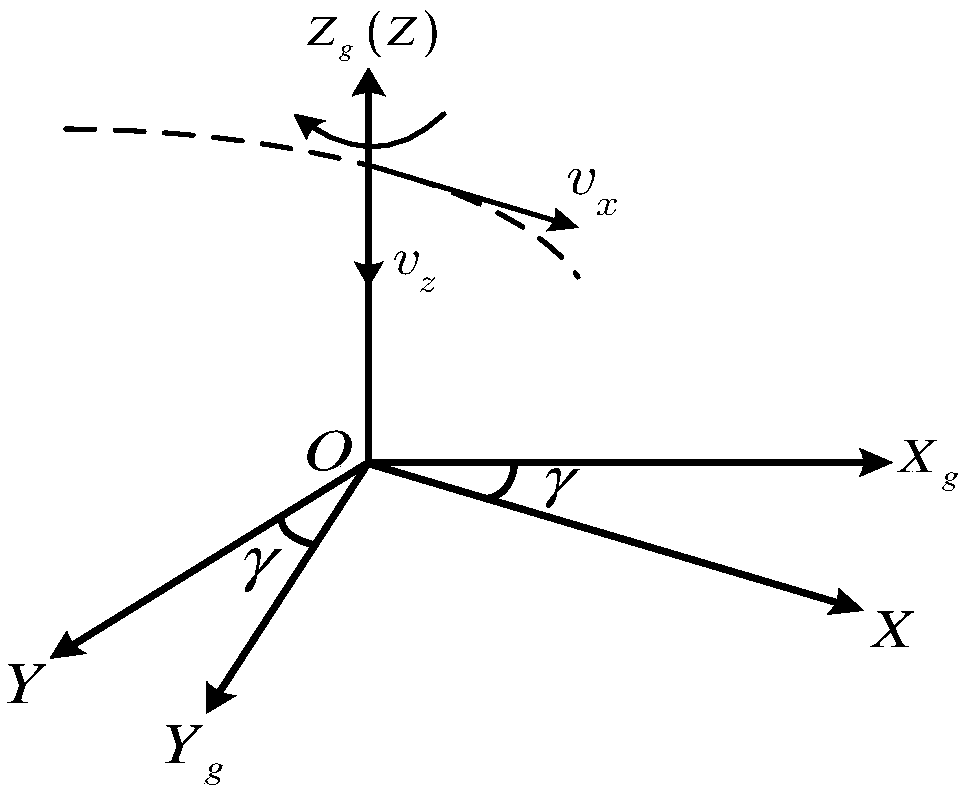

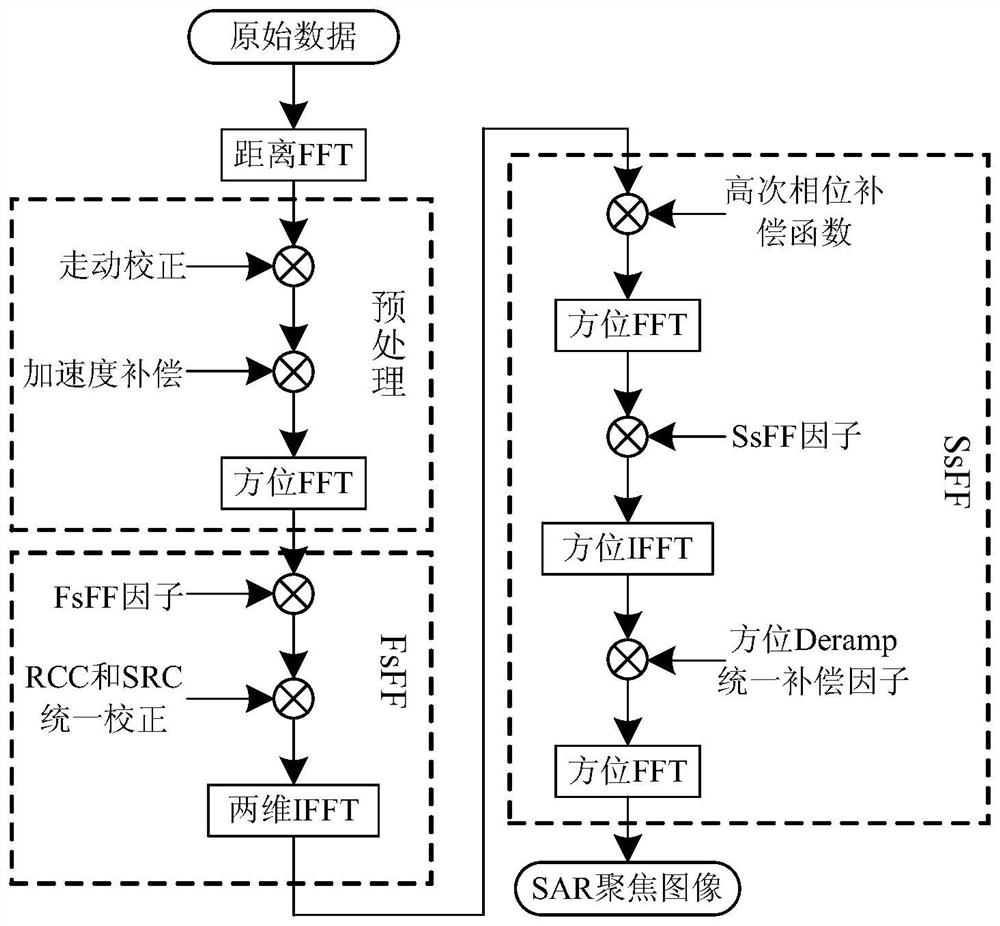

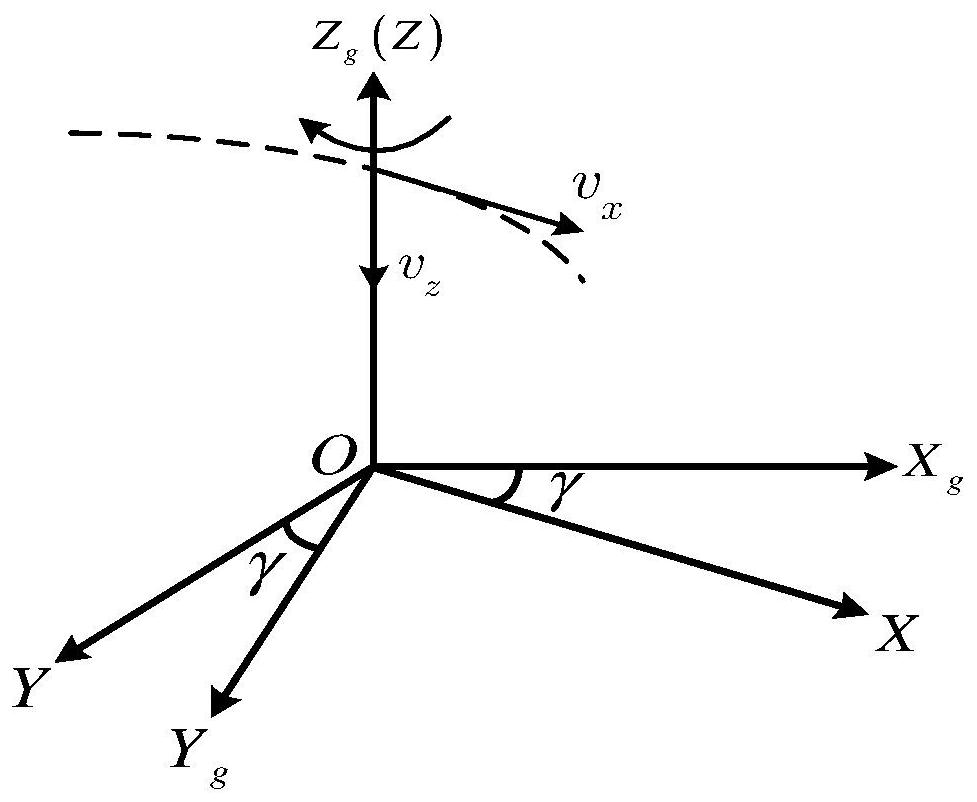

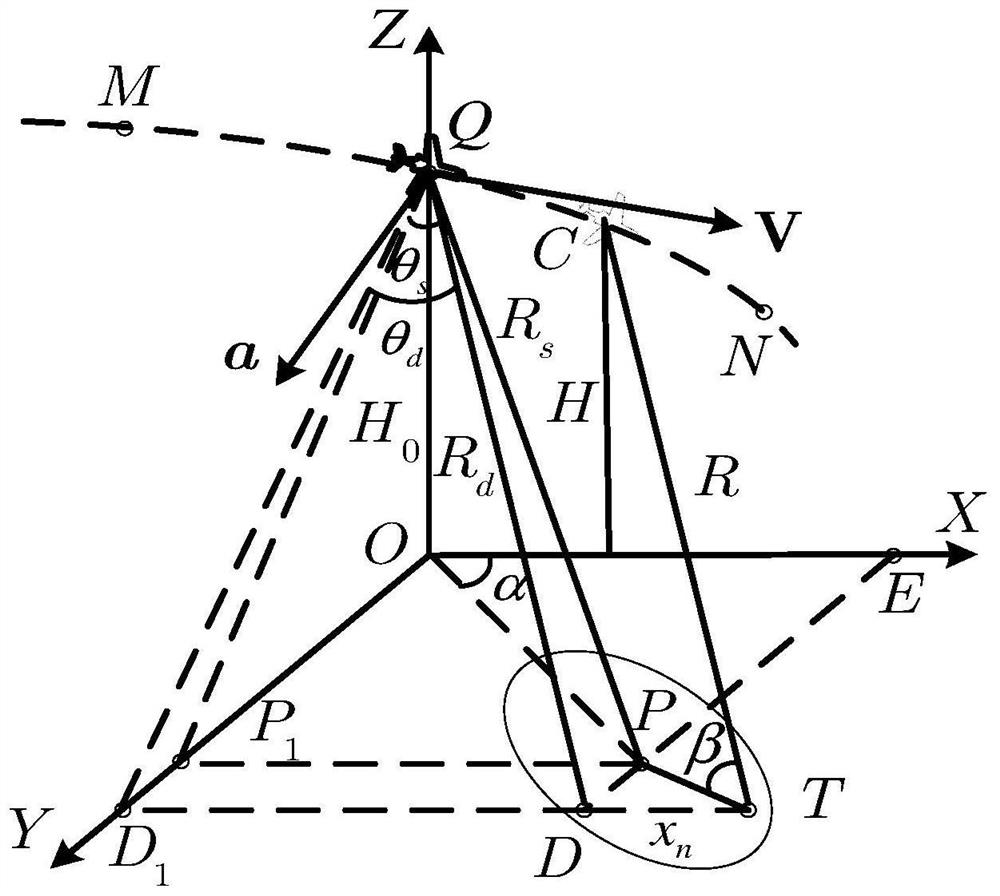

Diving movement high squint SAR sub aperture imaging space variance correction method based on two-stage filtering

ActiveCN108490441AAchieving unified calibrationNo blurringRadio wave reradiation/reflectionTime domainGeometric modeling

The invention belongs to the field of radar signal processing and discloses a diving movement high squint SAR sub aperture imaging space variance correction method based on two-stage filtering. An imaging geometric model is established, an original echo signal is subjected to range Fourier transform, a range walk correction and acceleration compensation function is constructed, and preprocessing is achieved. Then a compensated signal is transformed into a two-dimensional frequency domain, a first-order frequency domain filter factor is constructed to correct the space variance of a range envelope, a signal which is subjected to range direction process is transformed into an azimuth two-dimensional time domain through reverse Fourier transform, a high-order phase compensation function is constructed, then the compensated signal is transformed into an azimuth frequency domain, a second-order frequency domain filter factor is constructed to correct the space variance of azimuth Doppler parameters, a corrected signal is transformed into an azimuth time domain, and an azimuth unified compensation factor is constructed to implement the azimuth processing. Finally, a signal which is subjected to the azimuth processing passes an FFT to obtain the azimuth frequency domain to improve an azimuth focus depth.

Owner:XIDIAN UNIV

Method and apparatus for dynamic space-time imaging system

InactiveUS7961912B2Fast enough to eliminateNo blurringImage analysisMaterial analysis by optical meansSingle flash3d image

A method for creating a 3D map of the surface contours of an object includes projecting a variety of patterns onto the object, and imaging the patterns as they fall on the object to encode the topographic features of the object. In one embodiment a three dimensional image is taken in a single flash to avoid blurring due to motion of the object. Thereafter a secondary pattern is projected to detect changes in the initial image. The images are processed in a computer program in a manner such that a complete 3D map of the surface of the object is obtained in digital form. Reiteration of the method can detect motional variation such as a breathing human, flexure of a complex mechanical structure, or a stress-strain testing of an airplane, vehicle, beam, bridge, or other structure.

Owner:4D IMAGING +1

Production method of metal etching handicraft picture

The invention discloses a production method of a metal etching handicraft picture. The production method comprises the following steps of: exposing a black and white film on a substrate coated with metal photosensitive ink, performing developing treatment, cleaning, etching and re-cleaning in sequence, performing drying, wire drawing treatment and sealing, and storing a finished product. The production method has the advantages that an etching effect is good, especially for the handicraft picture with fine etching lines, as a side protective agent is added in etching liquid, grain marks are clear and complete when the handicraft picture is etched, the phenomenon that the grain marks are unclear caused by side corrosion cannot occur, a V-shaped structure is formed at the bottom of patterns in etching, the patterns and texts which are etched in the substrate show a stereo effect, especially the texts are etched, the stereo effect is good, and the patterns and fonts cannot discolor or deform so as to be convenient to keep for a long time. The etching method disclosed by the invention can be used for ensuring an attractive effect of the product, and is high in etching efficiency which is dozens of times that of a mechanical engraving machine, so that the working efficiency is greatly improved. The production method can be widely applied in multiple industries.

Owner:张永平

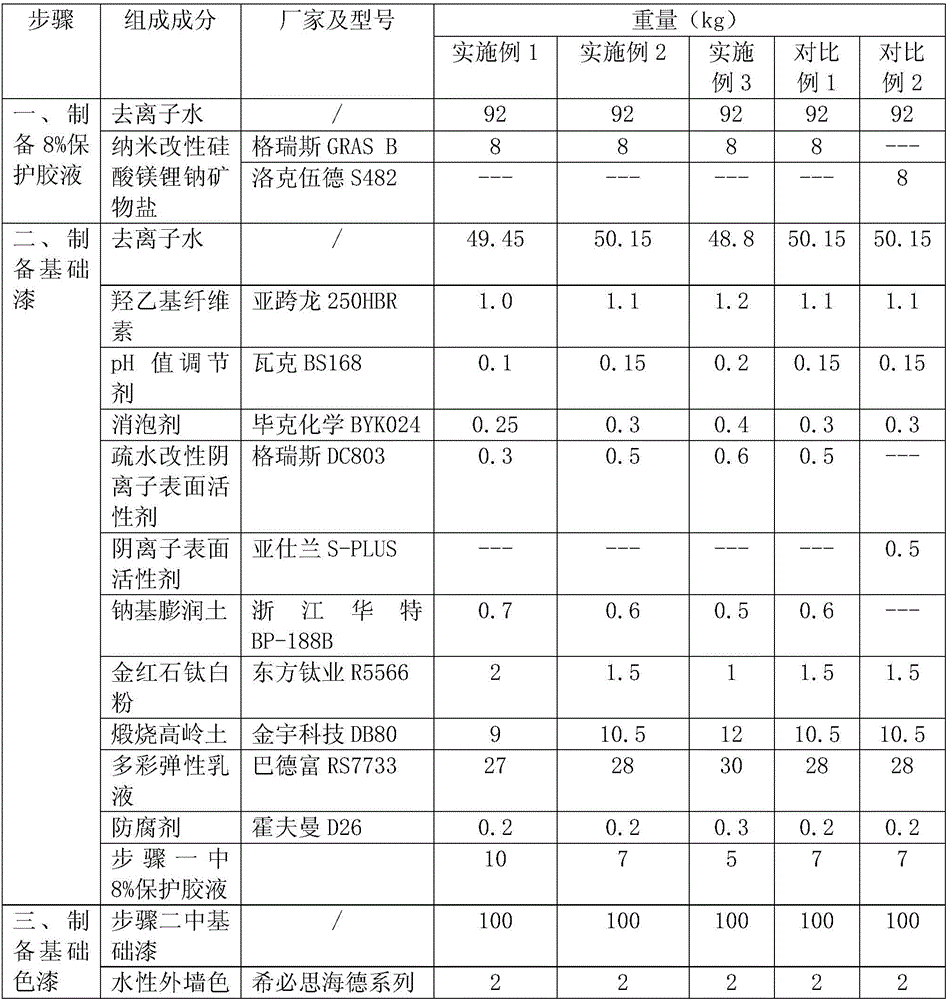

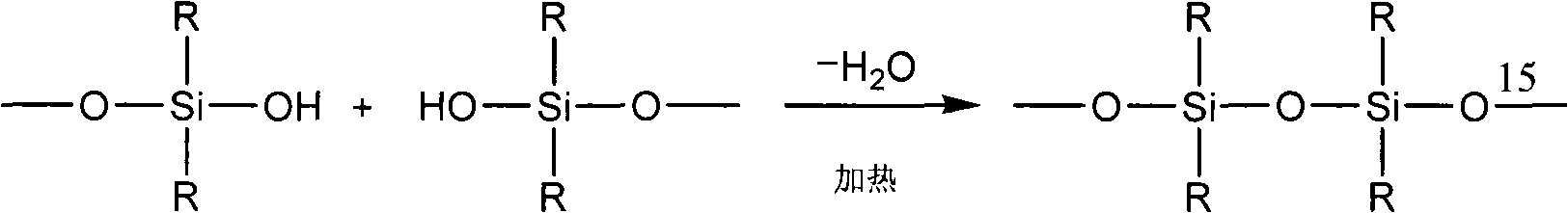

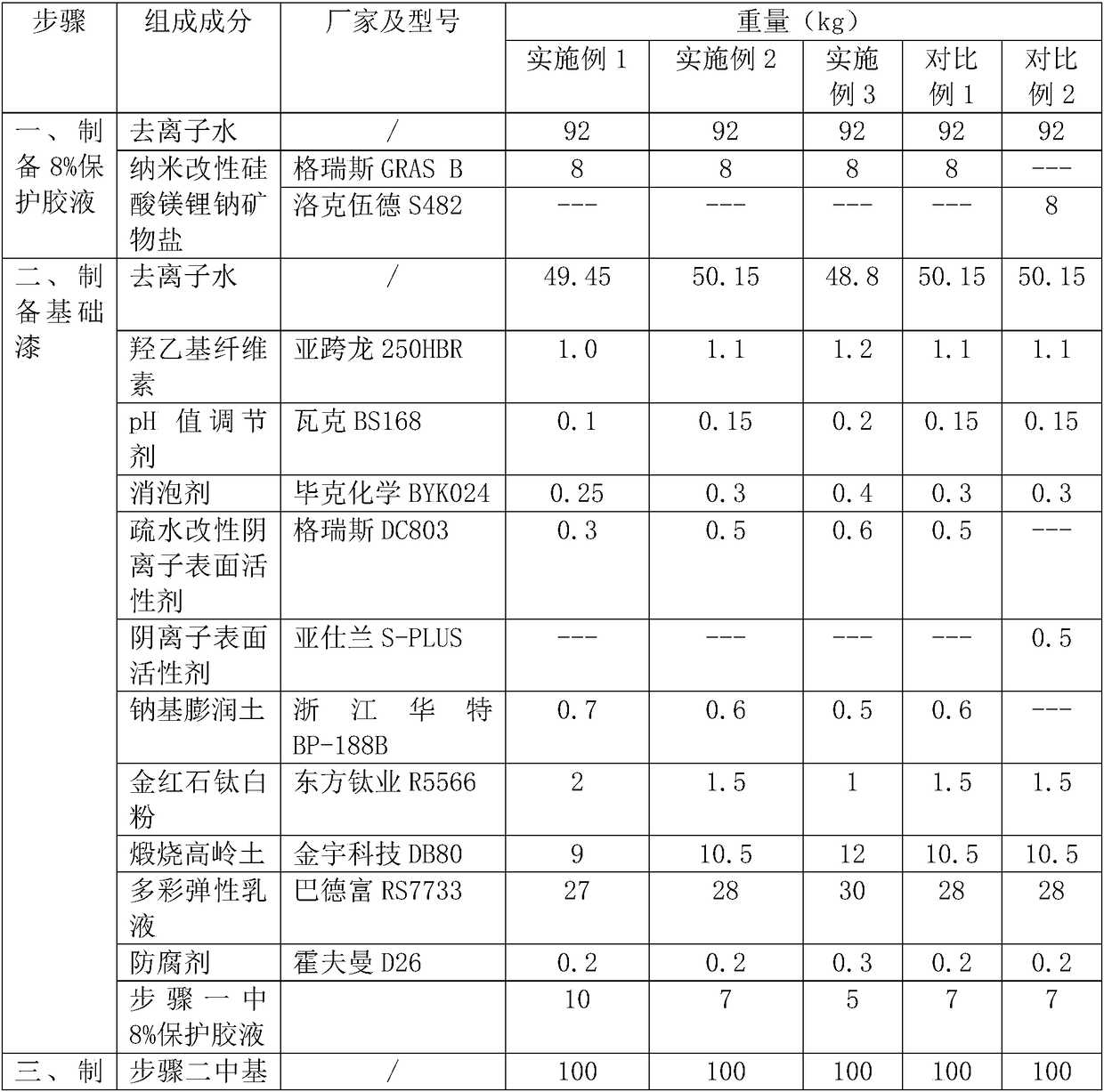

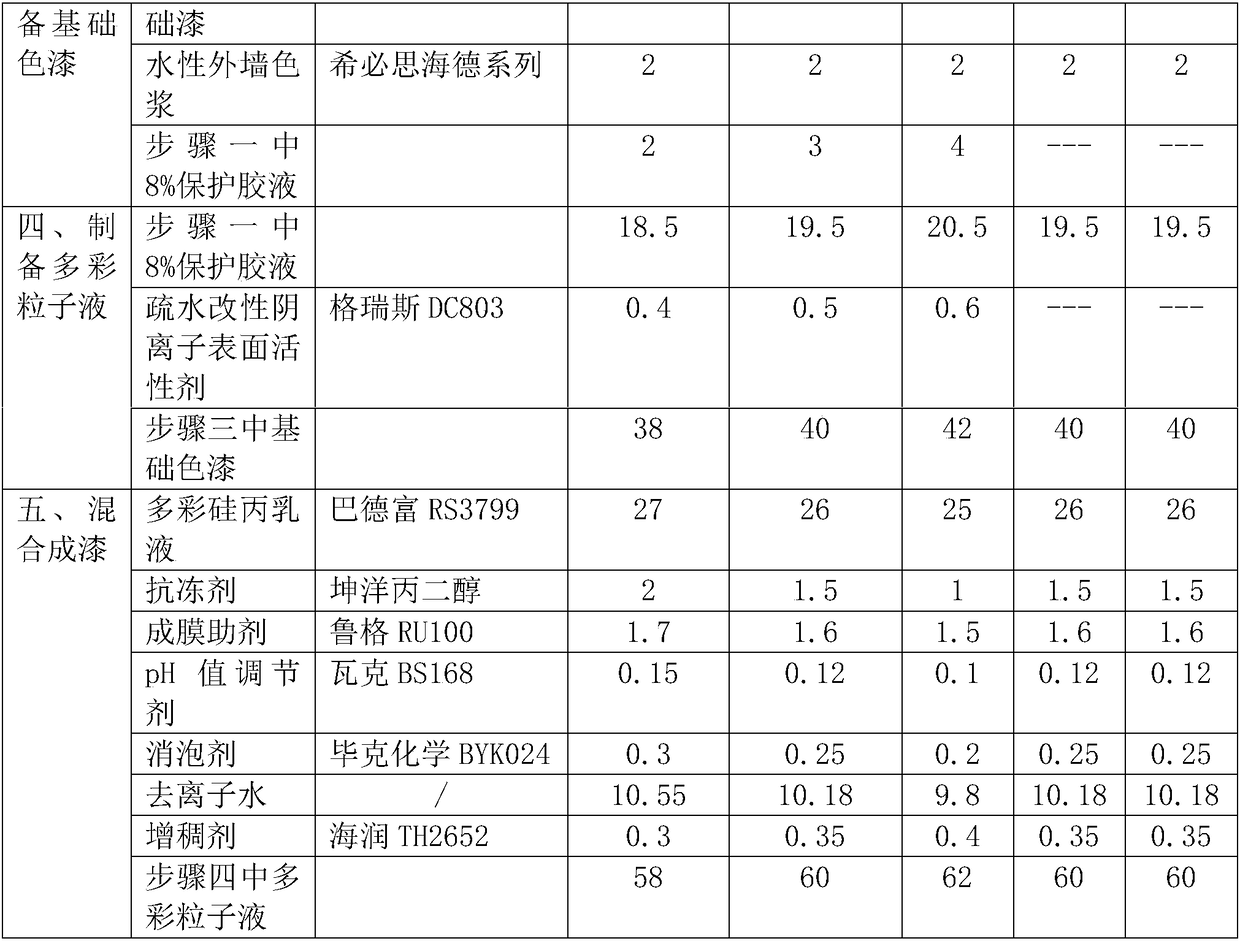

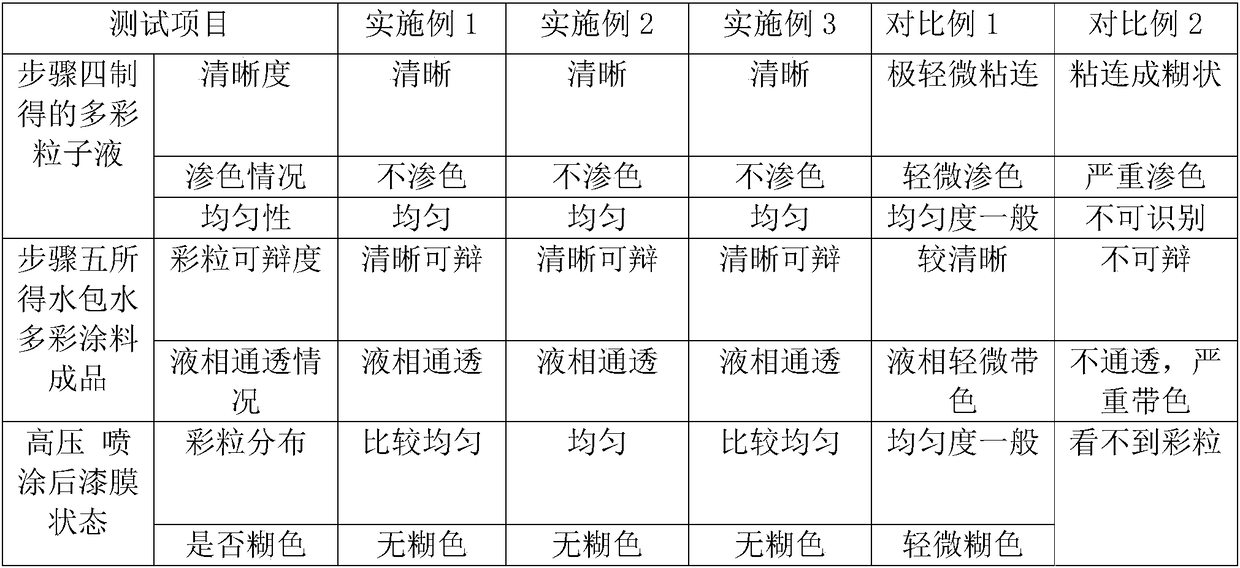

Water-in-water multicolor paint preparation method capable of high-speed slicing and granulation and paint prepared by method

ActiveCN106752567AGood mechanical strength and toughnessImprove ergonomicsMulticolor effect coatingsPelletizingChemistry

The invention discloses a water-in-water multicolor paint preparation method capable of high-speed slicing and granulation. The preparation process comprises the following steps: preparing an 8% protective glue solution; 2. preparing a basic paint; 3. preparing a basic color paint; 4. preparing a multicolor particle solution; and 5. preparing the water-in-water multicolor paint finished product. After the color matching is carried out on the basic paint, the 8% protective glue solution is utilized to perform system reinforcement; and in the granulation and slicing process, the 8% protective glue solution and a hydrophobic modified anionic surfactant are premixed, so that the negative-valence ions in the anionic surfactant sufficiently capture cations on the nano modified magnesium lithium sodium silicate mineral salt molecule surface to form a series of strict film structures, thereby eliminating the risk of rejection caused by color bleeding, fusion and thickening since colored particles can not be completely coated in time. Thus, the obtained water-in-water multicolor paint has the advantages of excellent mechanical strength, excellent toughness and high spraying efficiency. The invention also discloses a composition of the water-in-water multicolor paint.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Recording liquid and image recording method

InactiveUS6075085AHigh image densityImprove discharge stabilityLiquid surface applicatorsInksImage recordingPolymer chemistry

A recording liquid comprising a colorant, water and at least two kinds of fine resin particles. In a preferred embodiment, at least one of the two kinds of the fine resin particles are fine self-crosslinkable resin particles. In another preferred embodiment, the number of the kinds of the fine resin particles is 3 or more. Also, disclosed is an image recording method using the recording liquid.

Owner:FUJIFILM BUSINESS INNOVATION CORP

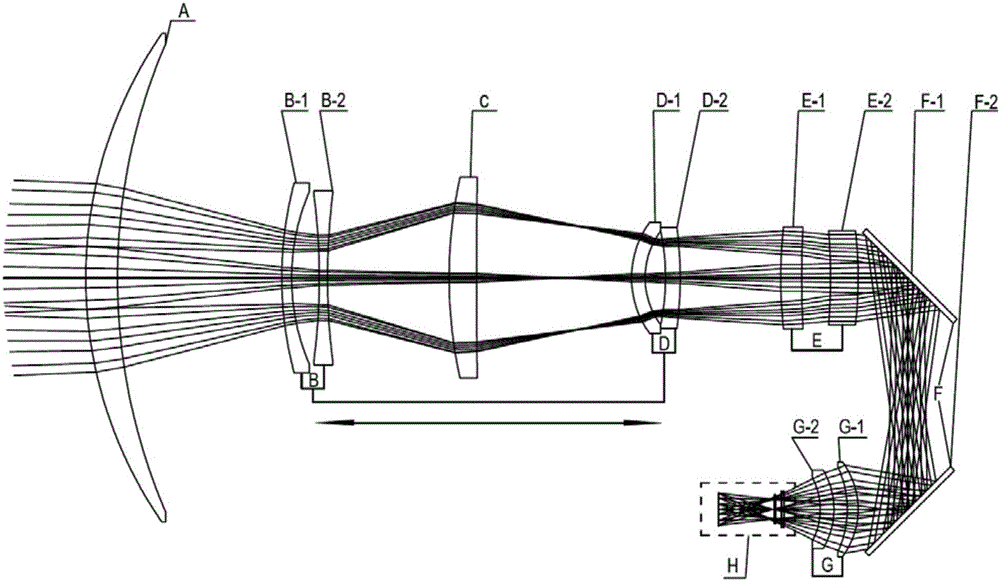

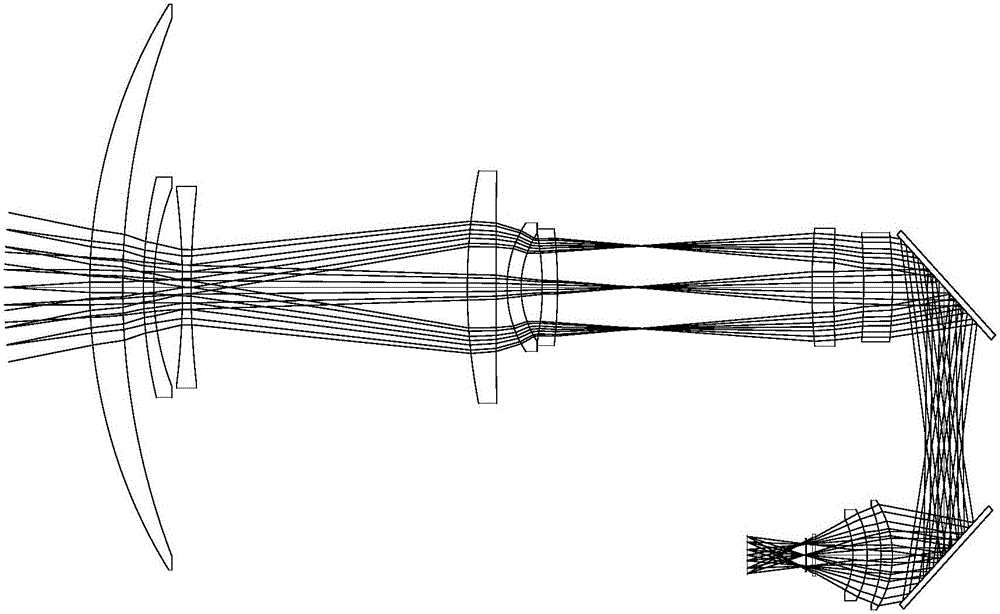

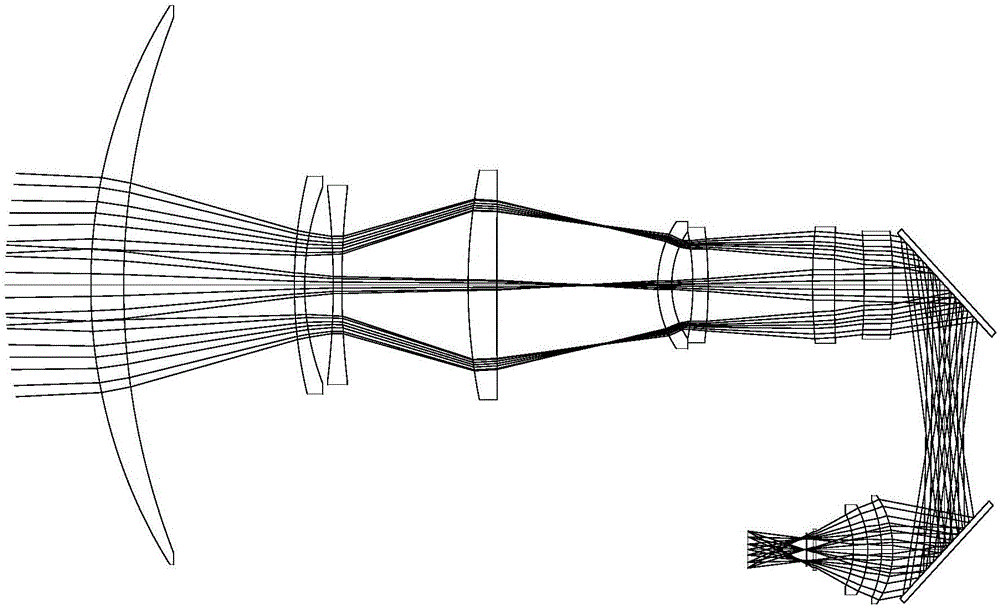

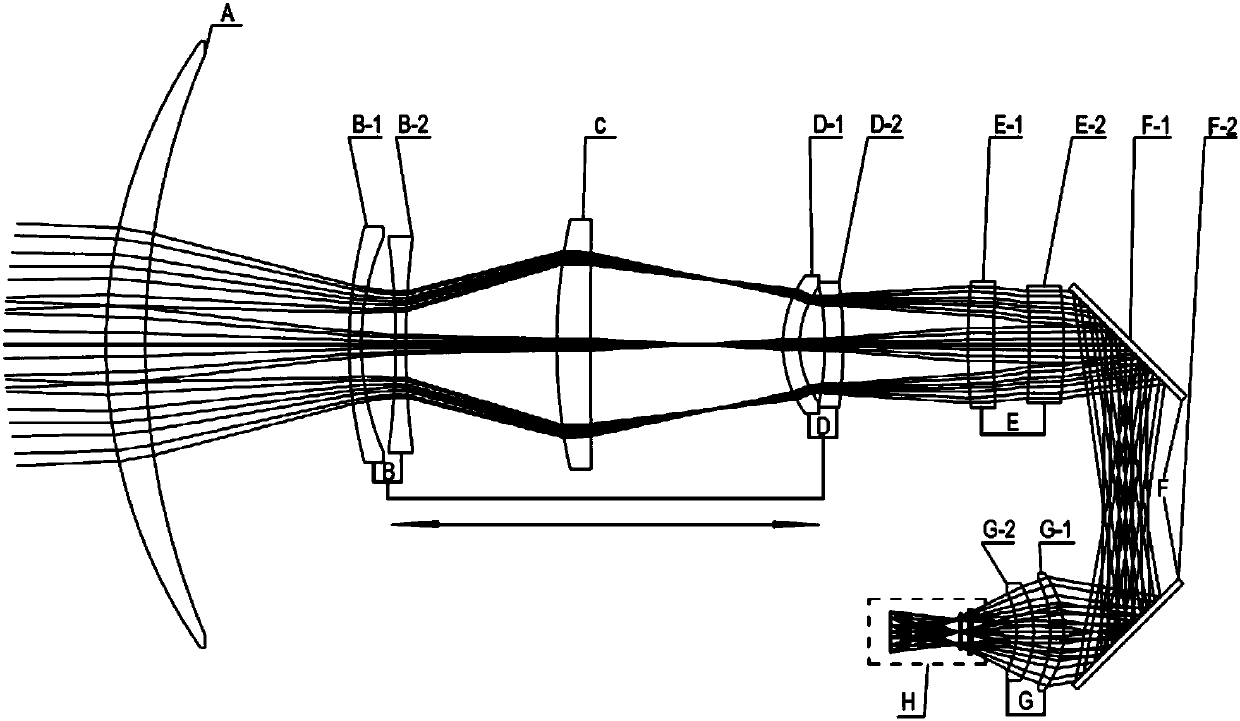

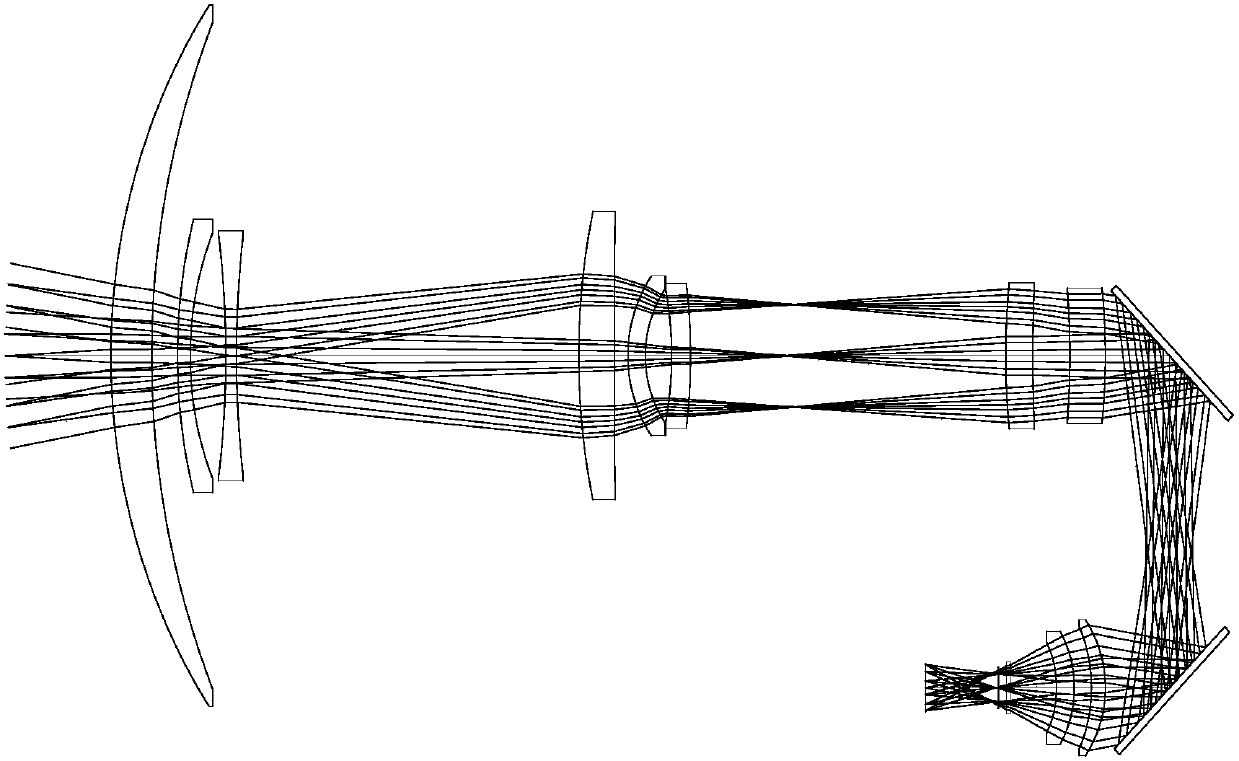

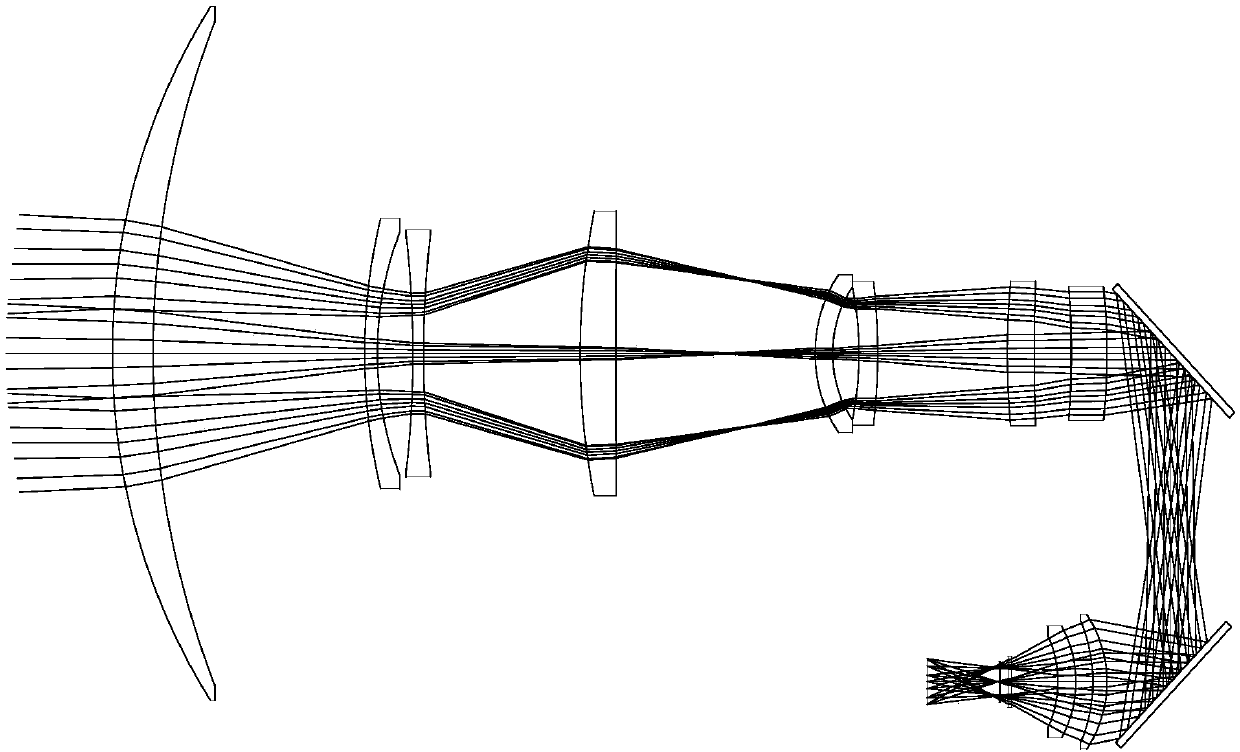

Optical compensation type long-wave infrared continuous zooming optical system

ActiveCN105676432ALong focal lengthHigh zoom ratioCamera body detailsOptical elementsOptical axisControl system

The invention relates to an optical compensation type long-wave infrared continuous zooming optical system, the system comprises a front fixed lens set, a front movable lens set, a middle fixed lens set, a rear movable lens set and a rear fixed lens set, the front movable lens set is formed by a first movable lens and a second movable lens arranged in sequence, the rear movable lens set is formed by a third movable lens and a fourth movable lens arranged in sequence, and the front movable lens set and the rear movable lens are ganged forward and backward with equal interval, equal speed and same direction to realize optical compensation type continuous zooming. The optical compensation type system has a simple structure which is easy to manufacture, and has relatively low precision requirement for controlling the system. A shortcoming that a mechanical compensation system needs precise cooperation of a complex cam structure or double leading screws to ensure image keeping clear in zooming process is overcome.

Owner:凯迈(洛阳)测控有限公司

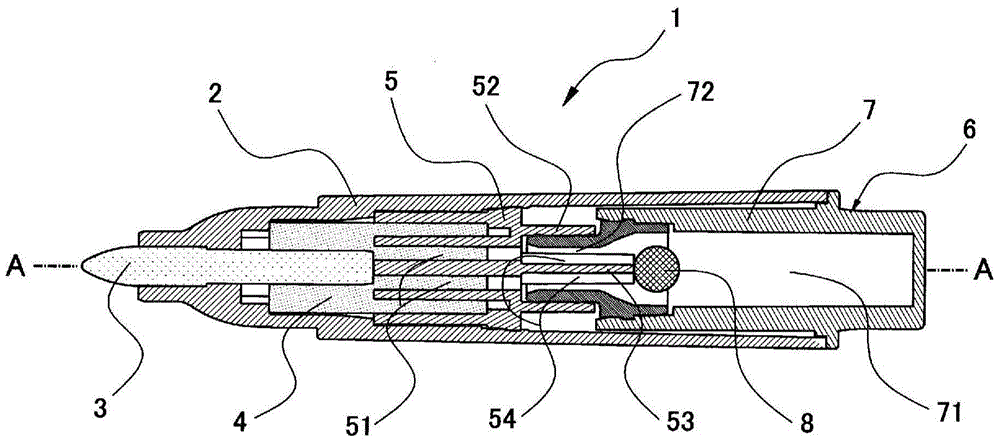

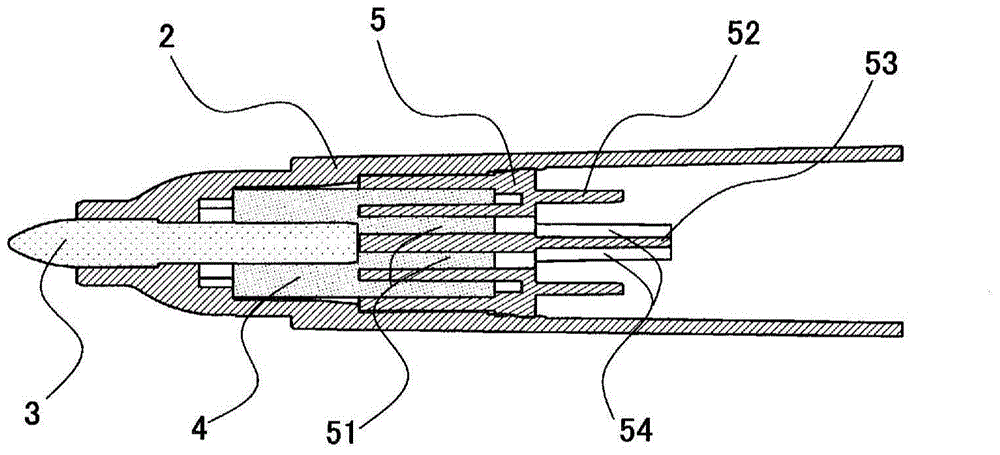

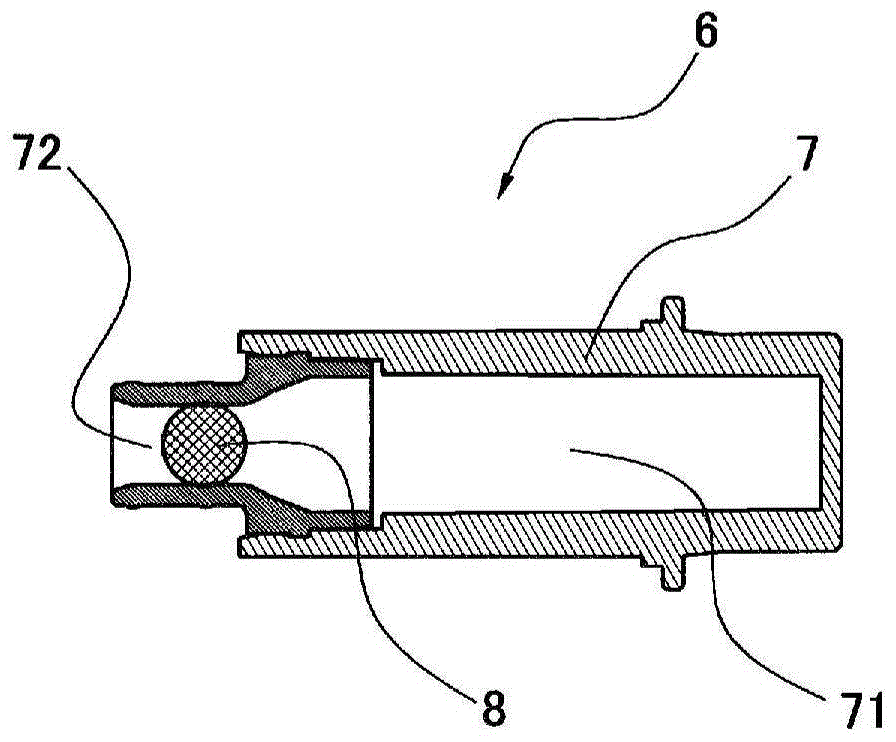

Wrtiting implement and ink cartridge

ActiveCN105050827AExcellent outflow stabilityImprove stabilityBall-point pensInk reservoir pensEngineeringMechanical engineering

Owner:PILOT PEN CO LTD

Dyed fabric and preparation method thereof

The invention provides a dyed fabric preparation method. The preparation method comprises the steps of: obtaining tung tree leaves, placing the tung tree leaves in water at 85 to 95 DEG C, and performing reflux extraction to obtain a tung oil leaf dye; placing a gray cloth in a modifier solution for modification treatment to obtain the modified gray cloth; taking the tung oil leaves and spreadingthe tung oil leaves on the modified gray cloth, placing the modified gray cloth with the tung tree leaves in a hot press for hot pressing, and printing the tung oil leaf pattern on the modified gray cloth; placing the modified gray cloth with the tung tree leaf pattern in the tung oil leaf dye for dyeing treatment; and placing the dyed modified gray cloth in a fixing agent solution for fixing treatment to obtain the product. The dyed fabric prepared by the above method has a large amount of dyeing, high color fastness to washing, and sunlight resistance.

Owner:ZHUHAI JIAN XUAN CLOTHING LTD

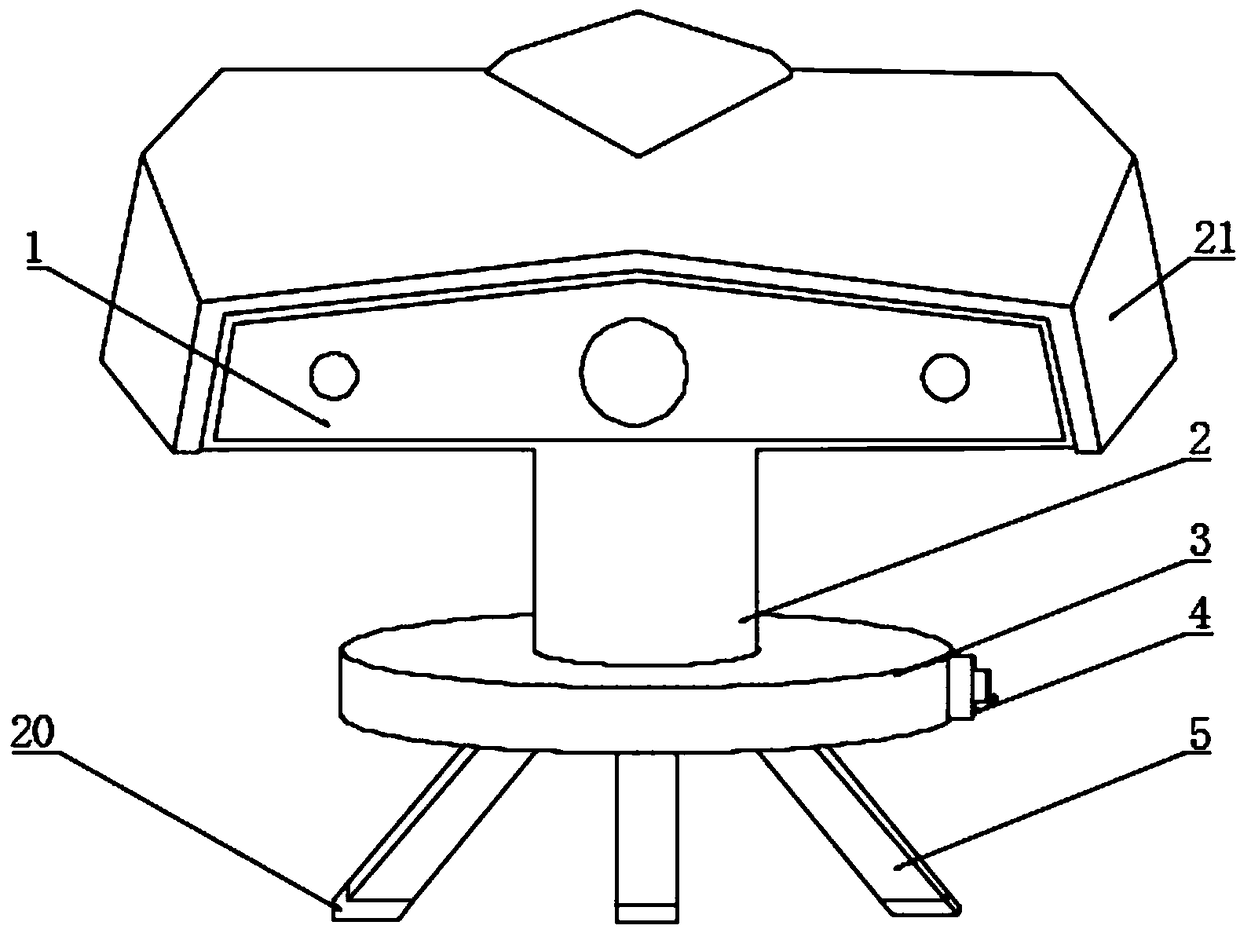

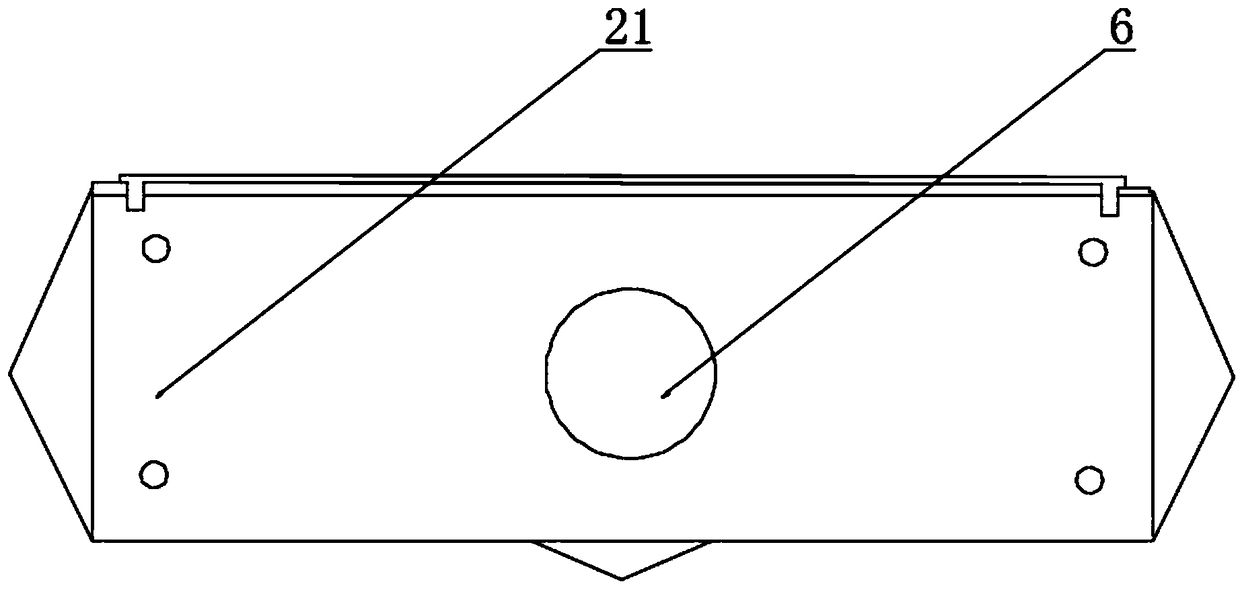

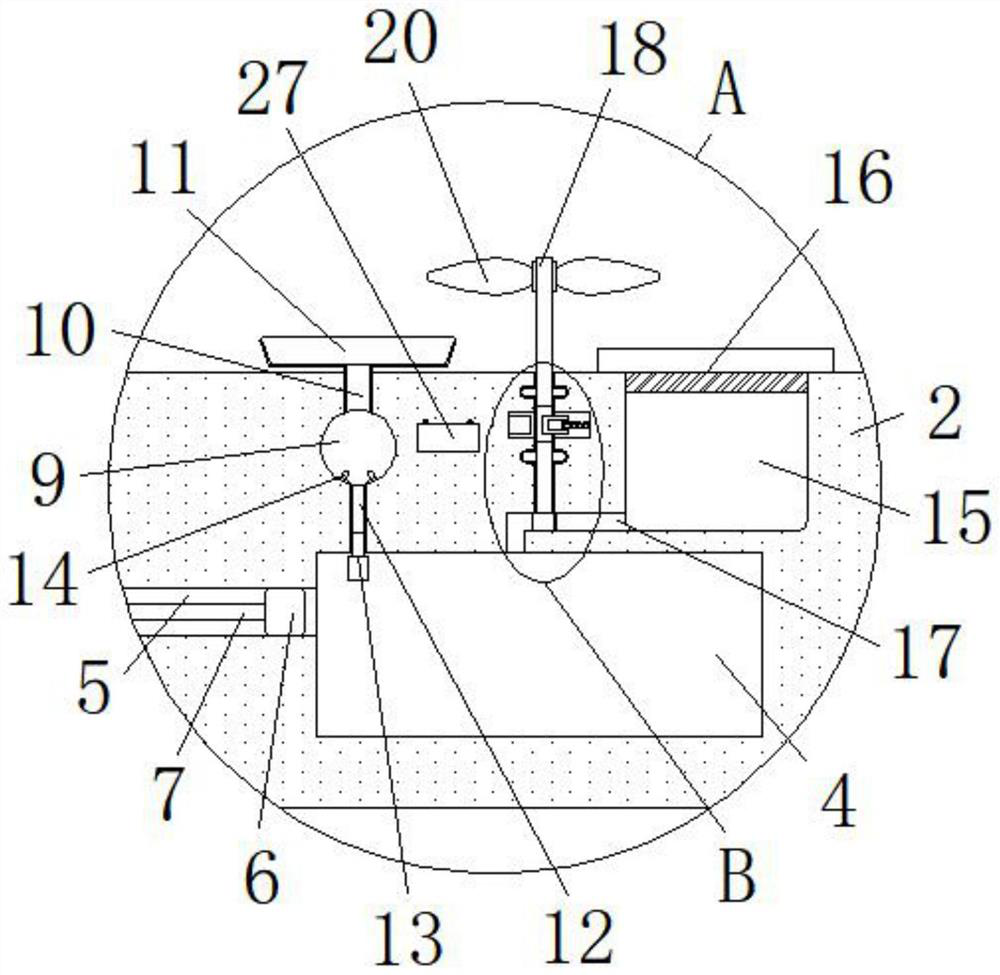

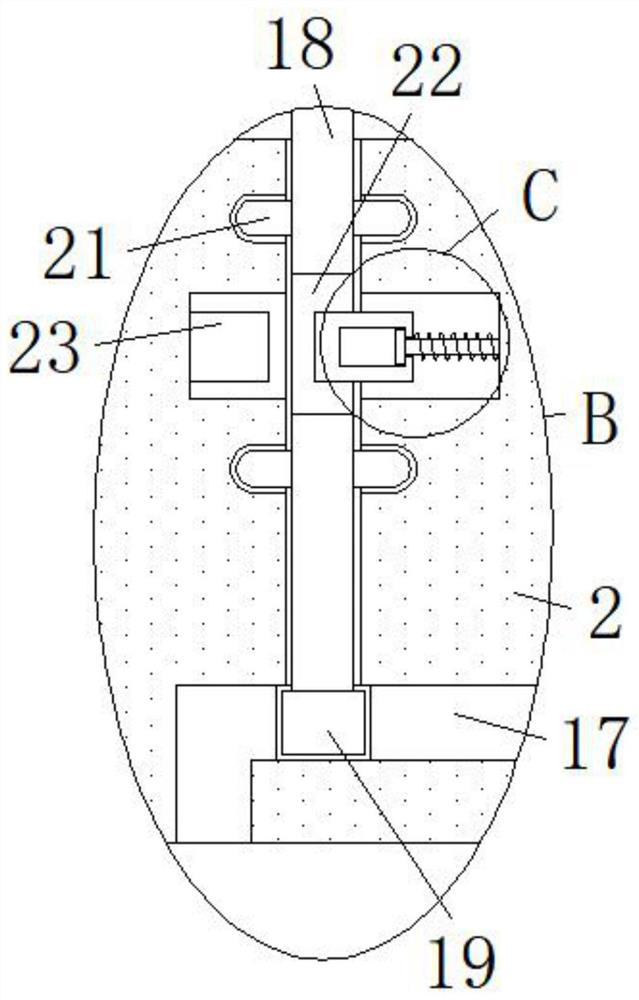

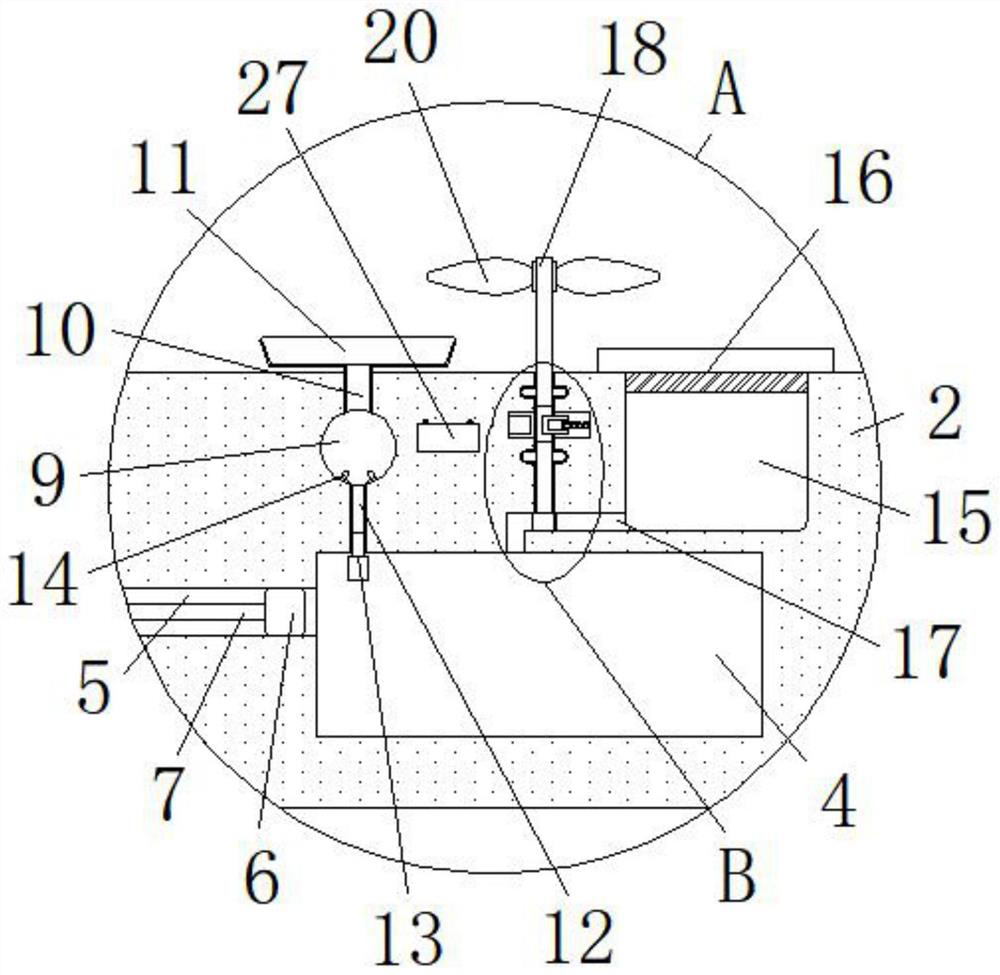

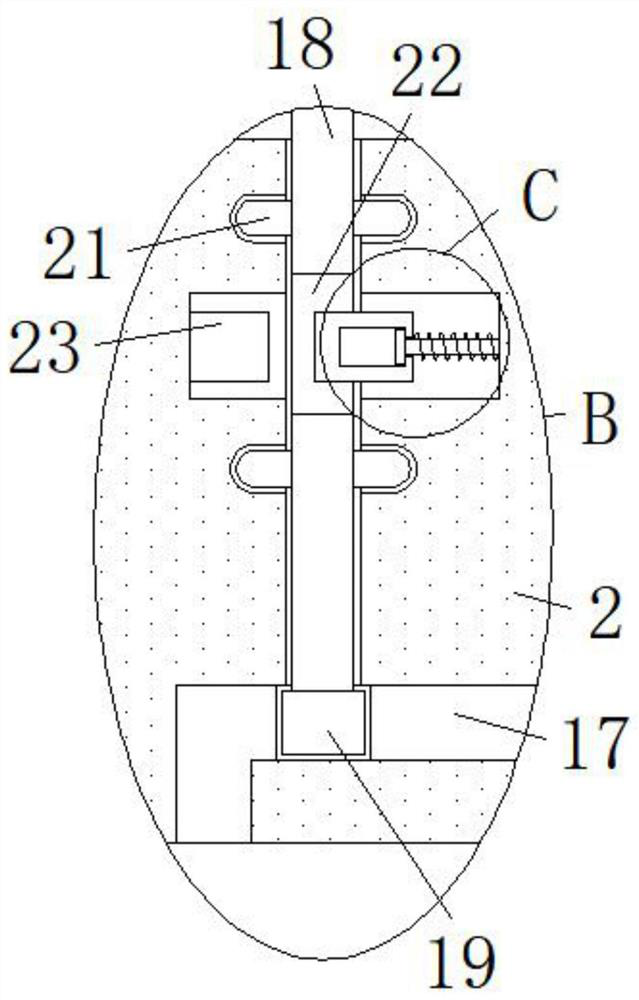

Storage type scanner for mine of ore-rock

The invention discloses a storage type scanner for mine of ore-rock, comprising a device body. The device body is provided with a dismounting hole in the middle of the bottom end, a rotating column isarranged in the middle of the inner side of the dismounting hole, a rotating disc is arranged at the bottom of the outer side of the rotating column, the rotating disc is provided with a limiting hole in the middle of the upper surface, and is provided with a groove in the bottom, the inner wall of one end of the groove is provided with a spring plate. The storage type scanner for the mine of ore-roc is scientific and reasonable in structure, safe and convenient to use, and is provided with an aluminum box and a buffer spring; the aluminum box can reduce the radiation of the scanner, and canreduce the harm of radiation to workers; the buffer spring can buffer the scanner when it falls to the ground; the damage lever of the internal structure of the scanner is reduced through the multipleprotections of the foam board and the aluminum box, the internal structure of the scanner is protected, the rotating column and the dismounting hole are separated by rotating the rotating column, sothat it is easy to carry, and the phenomenon of the extrusion damage of the scanner in the transportation way is reduced.

Owner:GUIZHOU UNIV

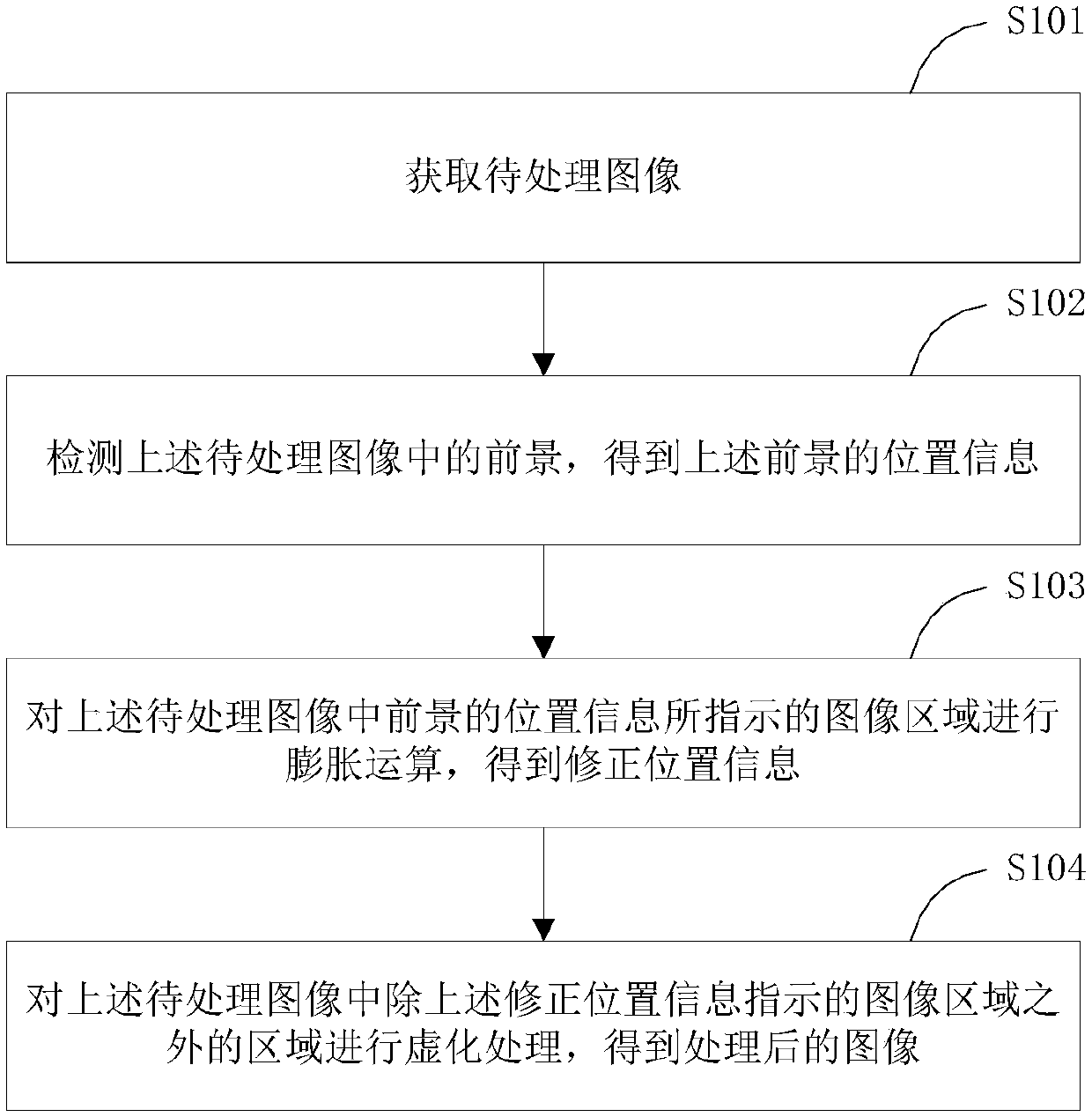

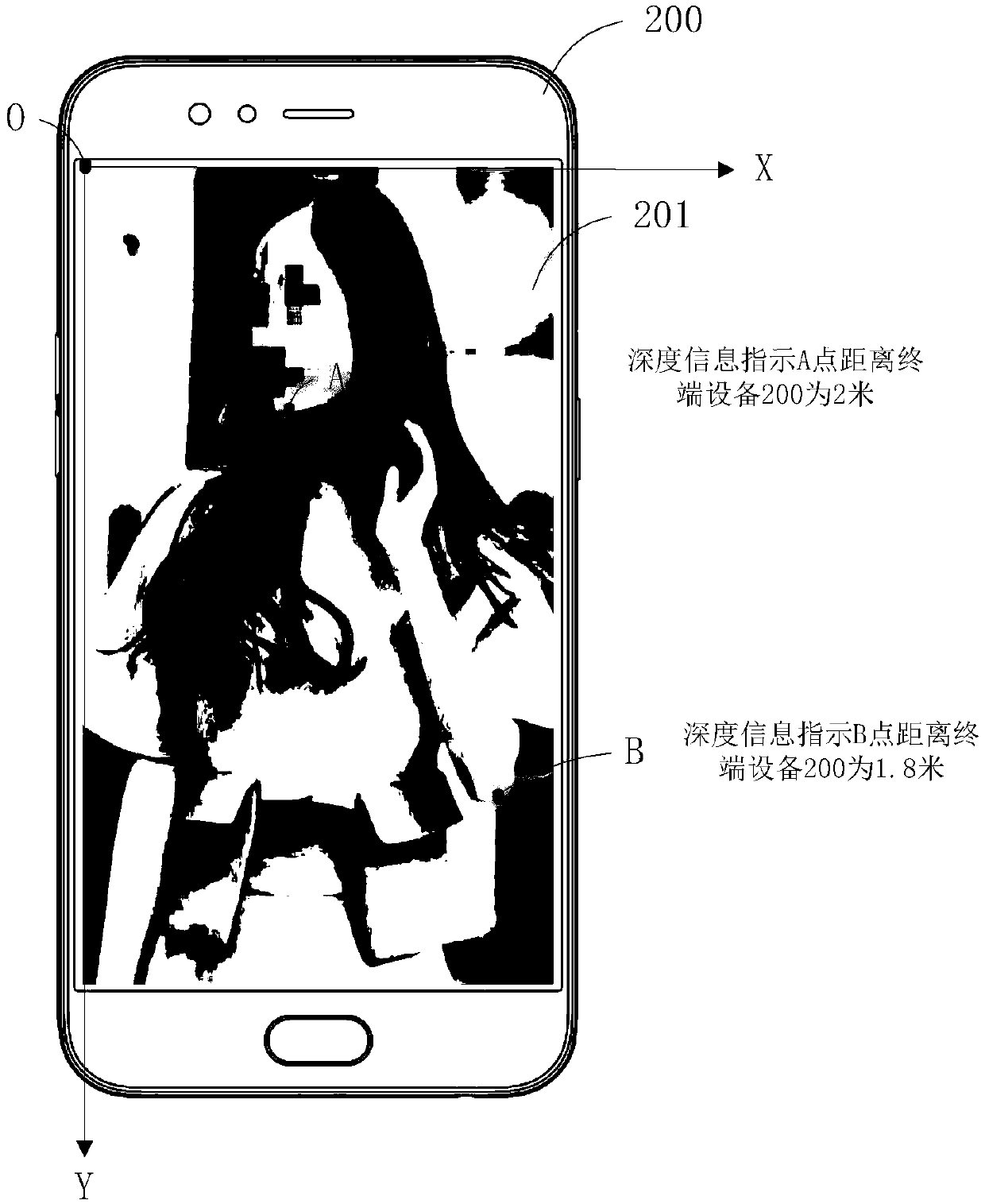

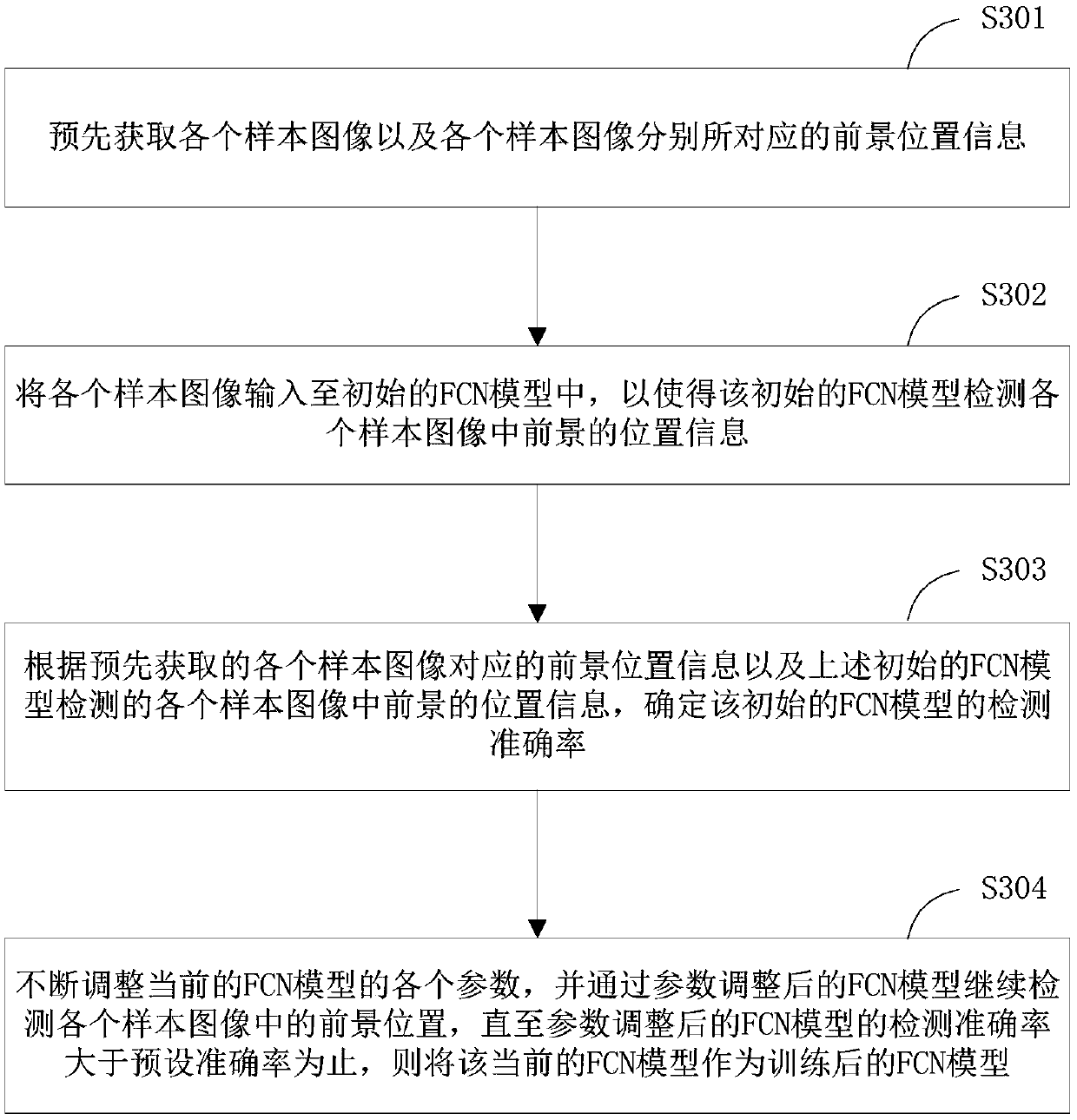

Image processing method, image processing device and terminal equipment

The invention provides an image processing method, an image processing device and terminal equipment. The method comprises the steps of obtaining a to-be-processed image; detecting a foreground in theto-be-processed image to obtain position information of the foreground; carrying out expansion operation on an image area indicated by the position information in the to-be-processed image to obtaincorrected position information; and performing blurring processing on an area, except the image area indicated by the correction position information, in the to-be-processed image to obtain a processed image. According to the invention, the blurred image can be more natural.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

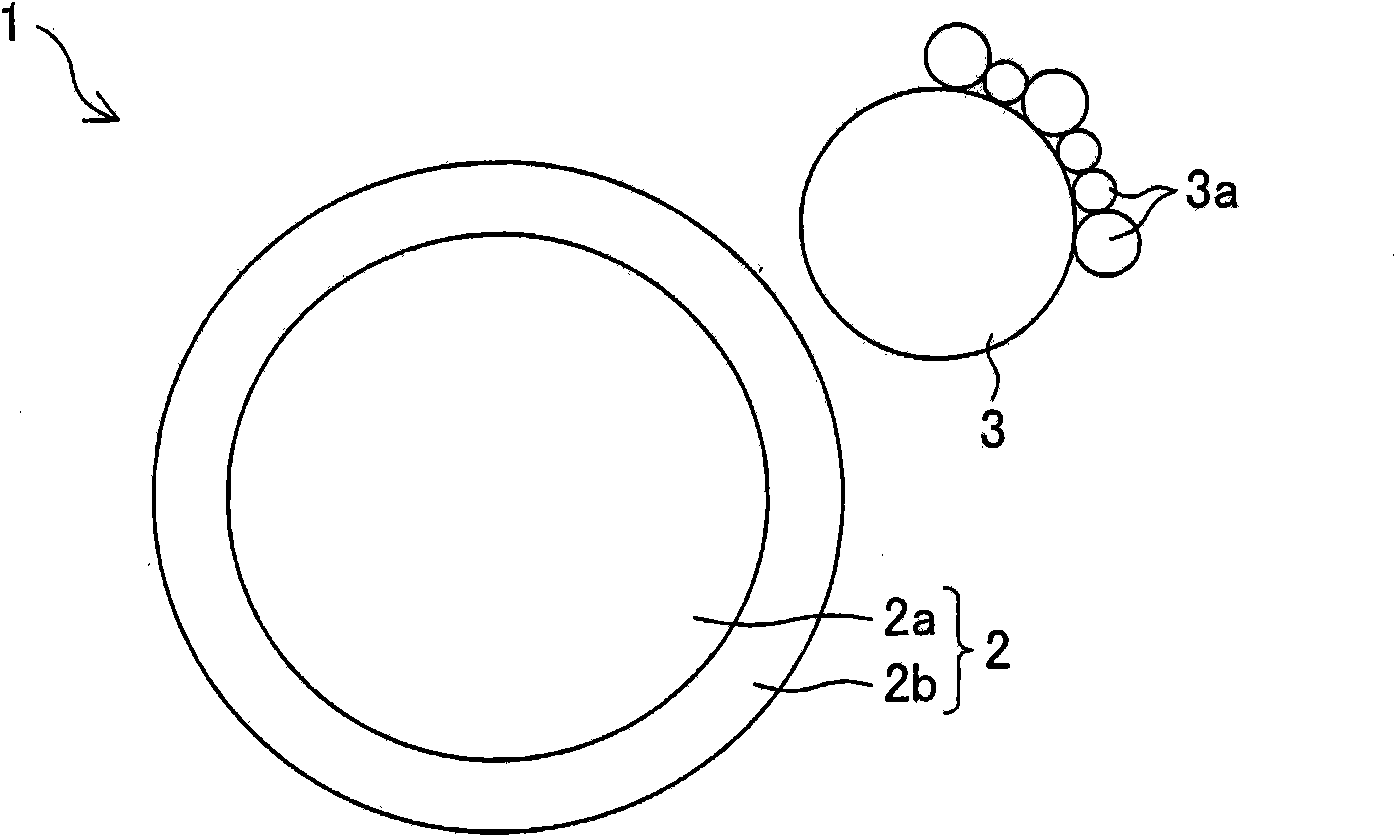

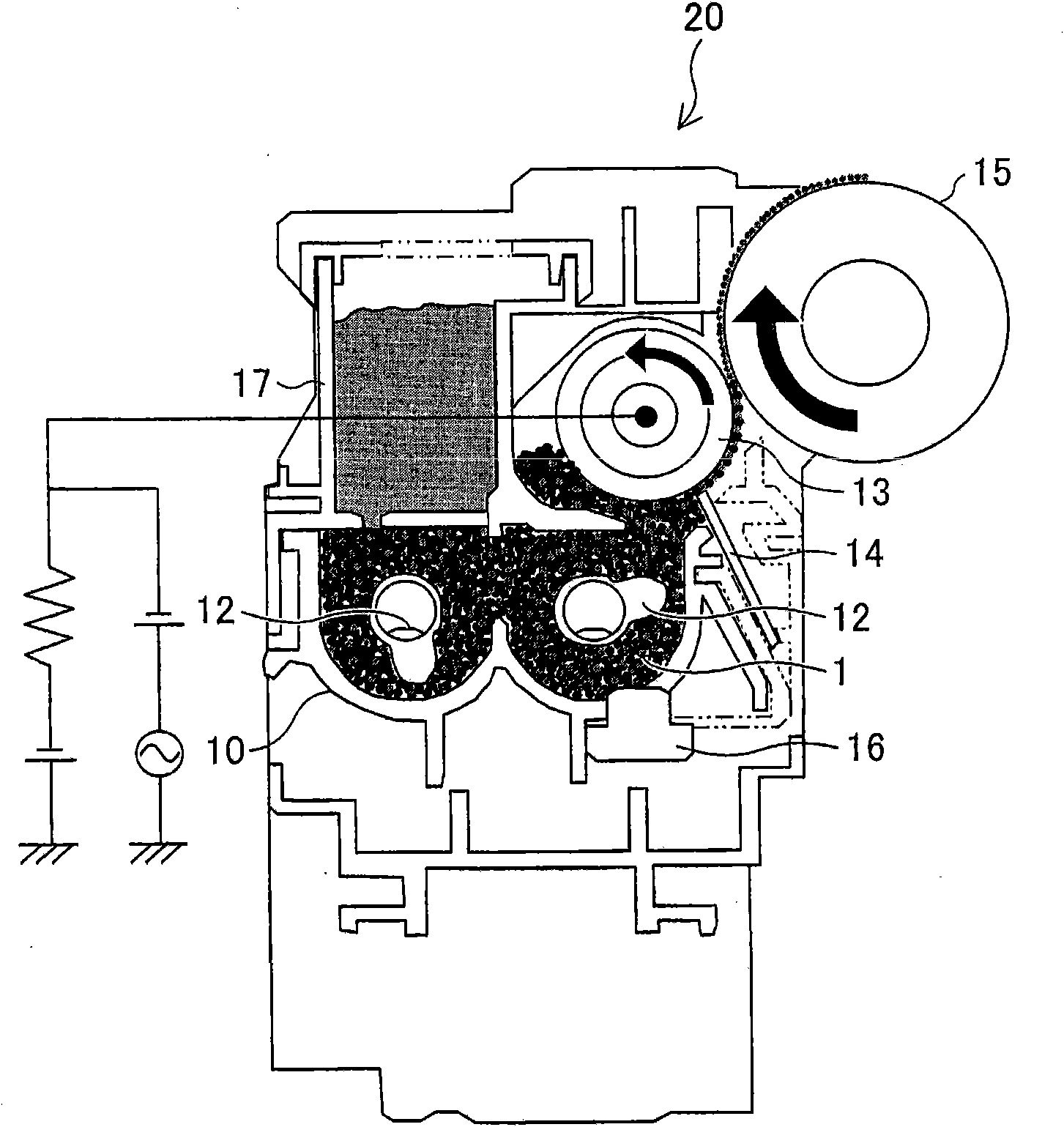

Magnetic carrier, two-component developer, developing unit, developing device, image-forming apparatus, and image-forming method

InactiveCN101681139ANo blurringStable outputDevelopersElectrographic process apparatusElectrical resistance and conductanceImage formation

Owner:SHARP KK

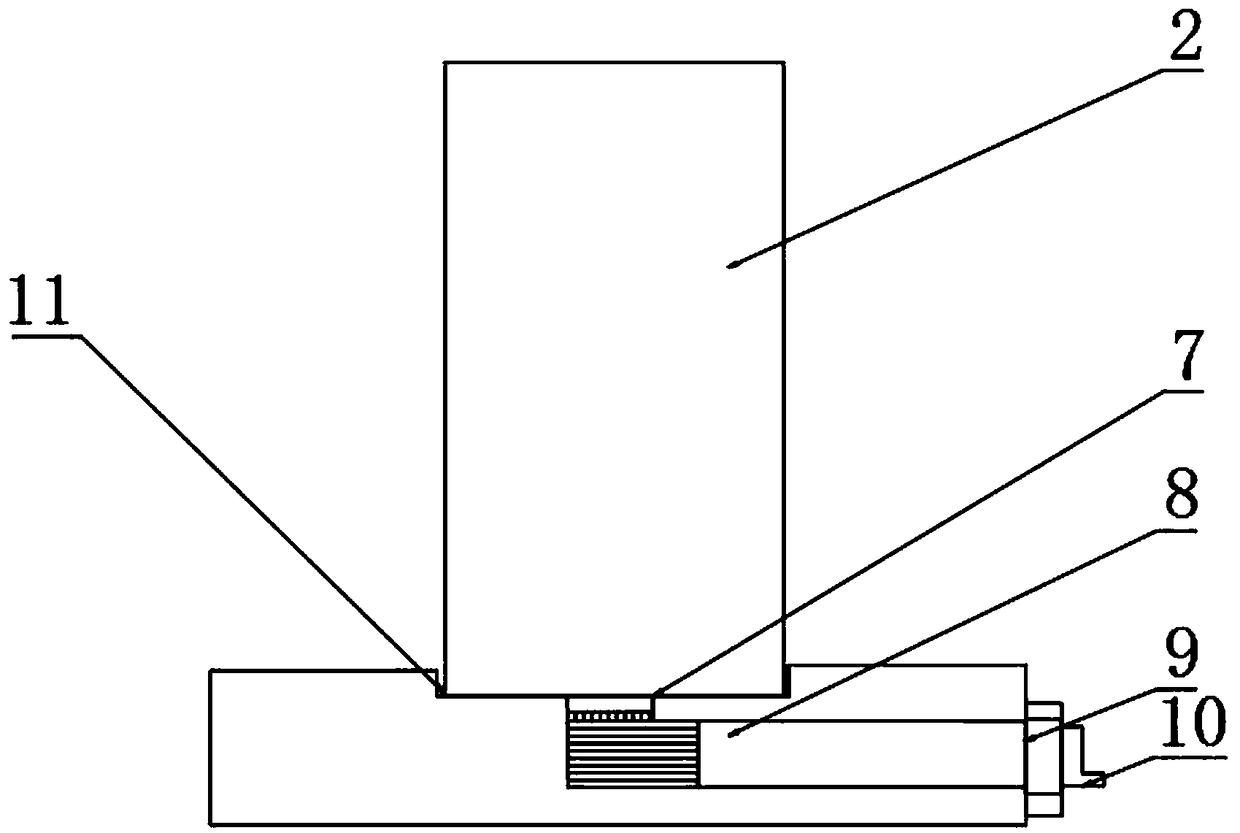

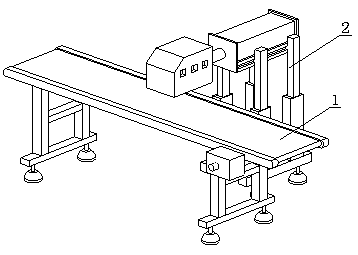

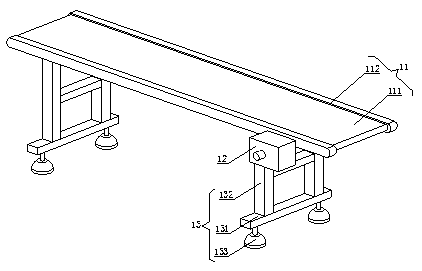

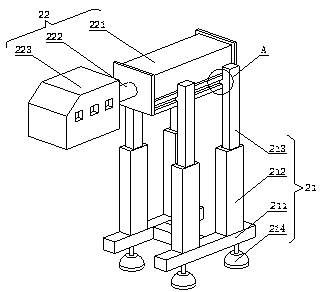

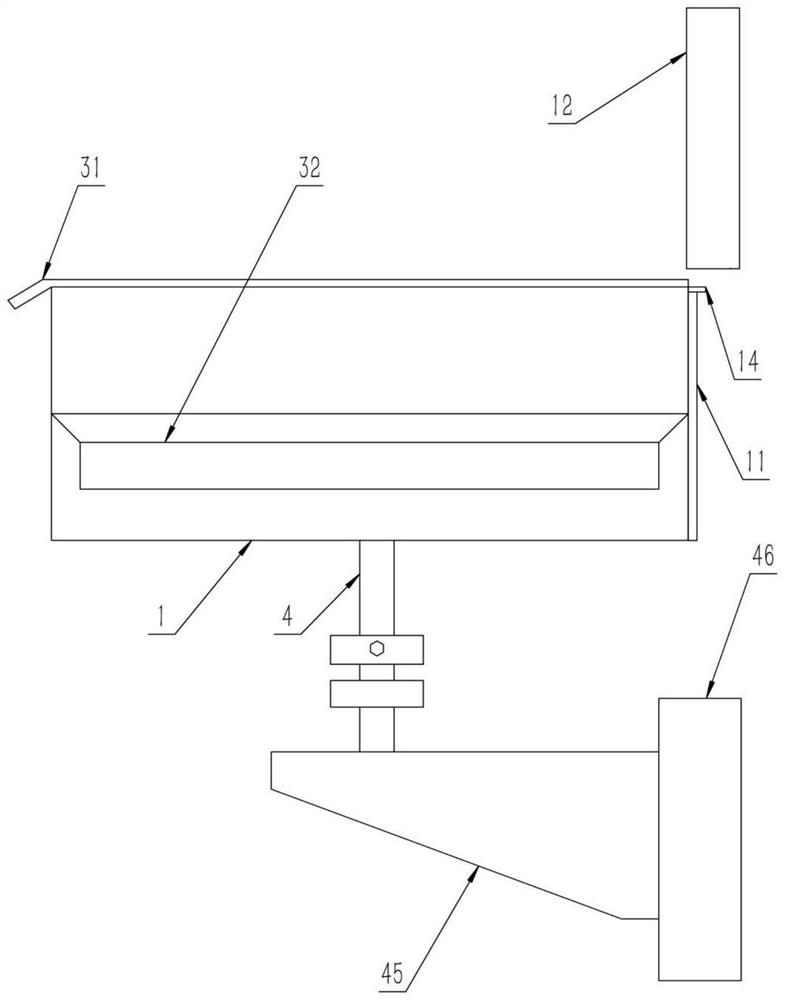

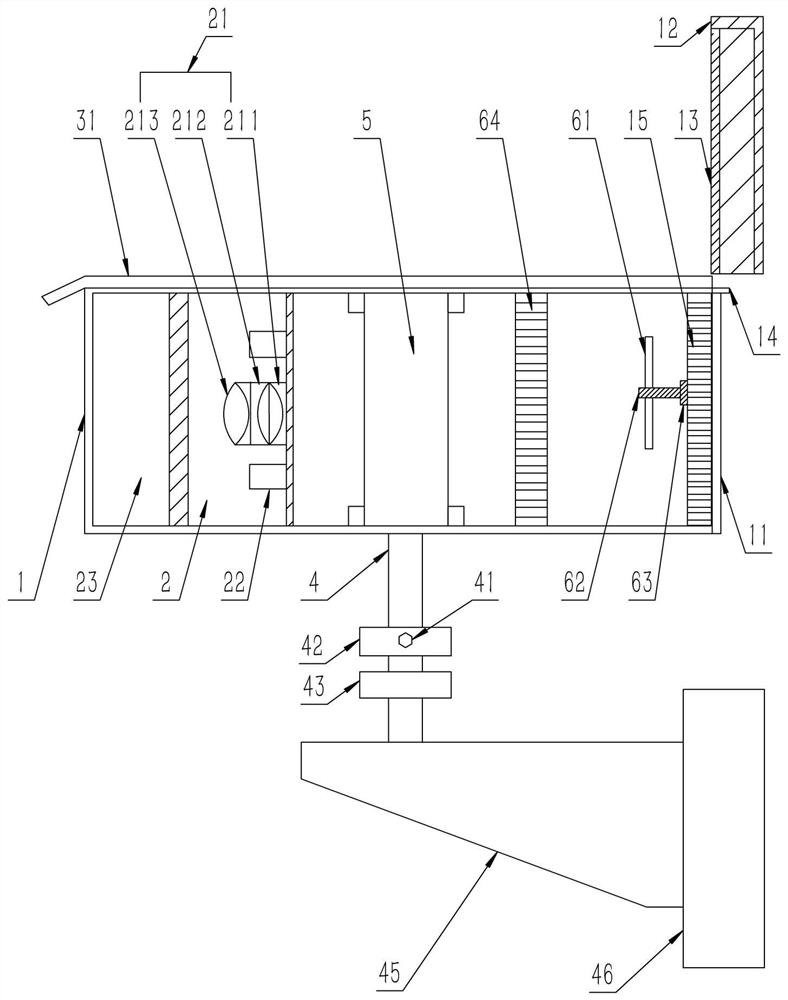

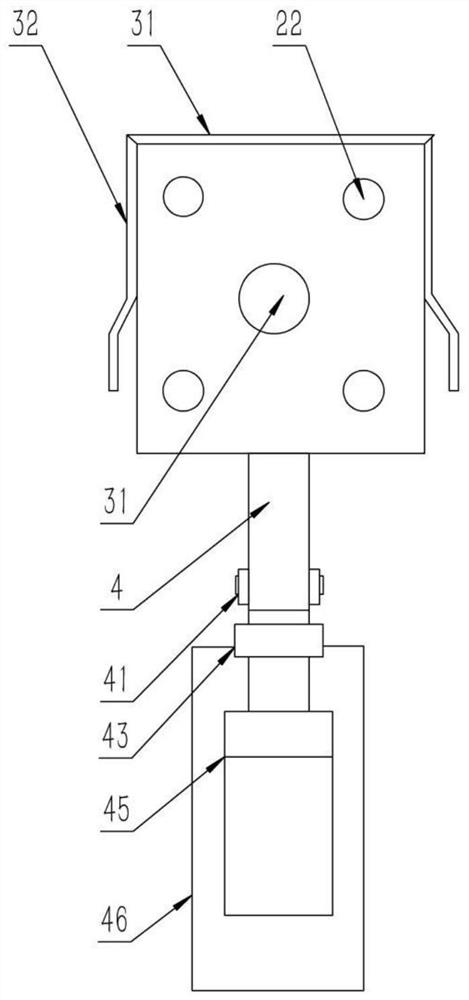

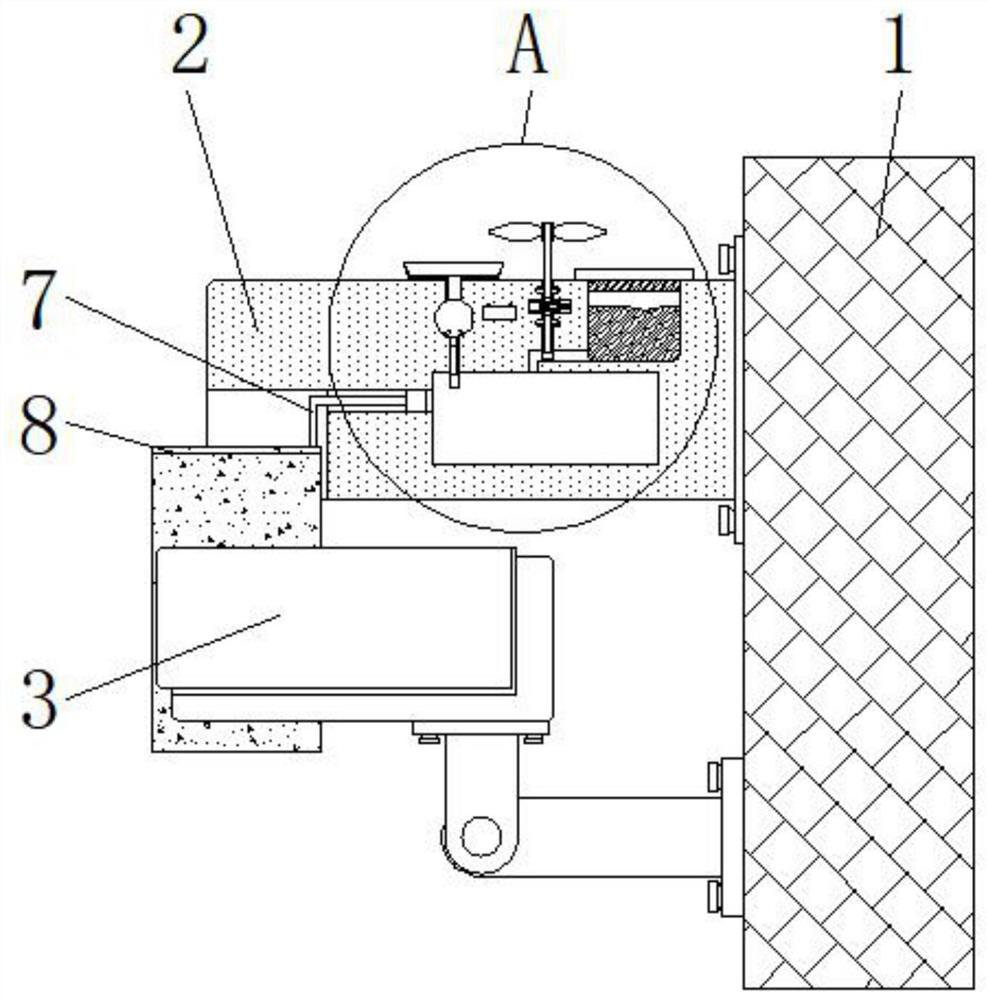

Label marking machine for heparin nano production and operation method thereof

PendingCN110640325ARealize marking automationSave human effortMetal working apparatusLaser beam welding apparatusRubber materialErbium lasers

The invention discloses a label marking machine for heparin nano production. The label marking machine comprises a conveying mechanism and a marking mechanism, wherein the marking mechanism is arranged on one side of the conveying mechanism, marking automation is achieved by arranging the conveying mechanism, manpower is saved, the working efficiency is improved, a conveying belt made of high-temperature-resistant rubber materials is arranged on a conveying belt assembly, grid baffles are arranged on the two sides of the conveying belt, so that the conveying belt cannot be damaged due to the high temperature generated by a fiber laser, the service life of the device is prolonged, and the grid baffles can prevent the marked products from falling out of the conveying belt. According to the label marking machine for heparin nano production and the operation method thereof, a stretchable supporting frame is arranged at the lower end of a laser marking device, so that the height of the laser marking device can be adjusted, so that the marking effect is better, and the fiber laser is arranged, so that the marking is clearer, and the phenomenon of blurring is avoided.

Owner:南通天瑞生物科技有限公司

A kind of preparation method and coating of water-in-water colorful paint capable of high-speed slicing and granulation

ActiveCN106752567BNo risk of breakage and bleedingHigh mechanical strengthMulticolor effect coatingsLithiumSodium silicate

The invention discloses a water-in-water multicolor paint preparation method capable of high-speed slicing and granulation. The preparation process comprises the following steps: preparing an 8% protective glue solution; 2. preparing a basic paint; 3. preparing a basic color paint; 4. preparing a multicolor particle solution; and 5. preparing the water-in-water multicolor paint finished product. After the color matching is carried out on the basic paint, the 8% protective glue solution is utilized to perform system reinforcement; and in the granulation and slicing process, the 8% protective glue solution and a hydrophobic modified anionic surfactant are premixed, so that the negative-valence ions in the anionic surfactant sufficiently capture cations on the nano modified magnesium lithium sodium silicate mineral salt molecule surface to form a series of strict film structures, thereby eliminating the risk of rejection caused by color bleeding, fusion and thickening since colored particles can not be completely coated in time. Thus, the obtained water-in-water multicolor paint has the advantages of excellent mechanical strength, excellent toughness and high spraying efficiency. The invention also discloses a composition of the water-in-water multicolor paint.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

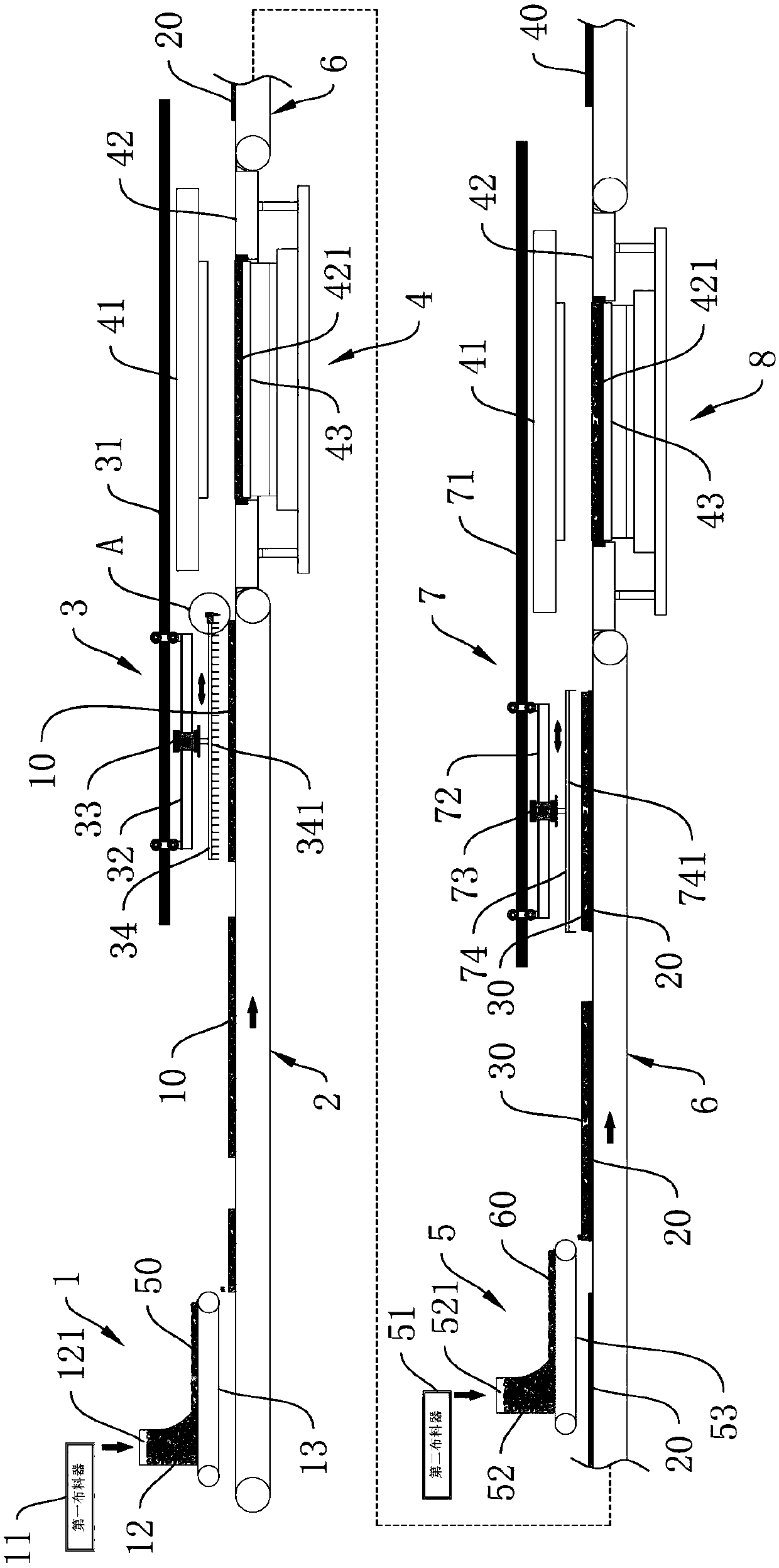

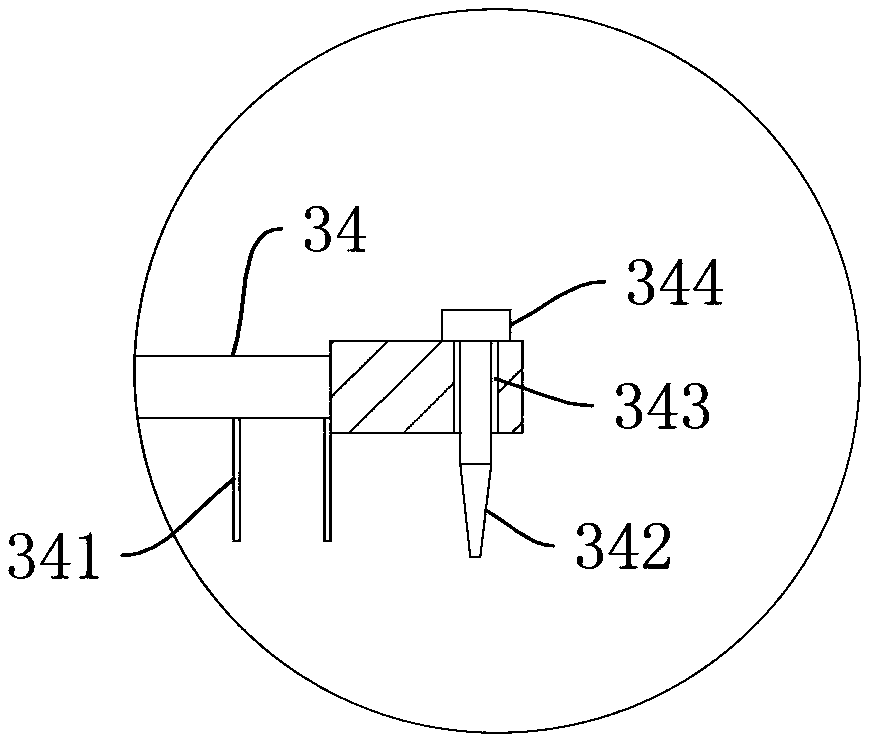

Forming production process for ceramic full-body tile adobe

ActiveCN110856957ASmall amount of deformationImprove realismCeramic shaping plantsFeeding arrangmentsSurface patternAdobe

The invention relates to a forming production process for a ceramic full-body tile adobe. The used hardware comprises a first distributing device, a first conveying belt assembly, a mold-keeping material pushing device, a first stamping forming device, a second distributing device, a second conveying belt assembly, a mold-keeping pushing device and a second stamping forming device; during processing, a first raw material pile is formed firstly, then the first raw material pile is stamped into a small adobe, then a second raw material pile is distributed on the small adobe, and finally the small adobe and the second raw material pile are stamped together to obtain the full-body tile adobe. The ceramic full-body tile adobe product processed by the production process has more realistic full-body effect, consistent full-body patterns and textures, no deformation or distortion of patterns or textures, no dragging marks or fuzzy phenomena on the surface patterns and textures, the ceramic full-body tile adobe product can realize and maintain the design effect required by distribution truly and perfectly, is beneficial to realizing the effect of directly distribution textures, and a background glaze is not needed to be coated, so the quality and market competitiveness of the full-body tile are improved.

Owner:刘建新

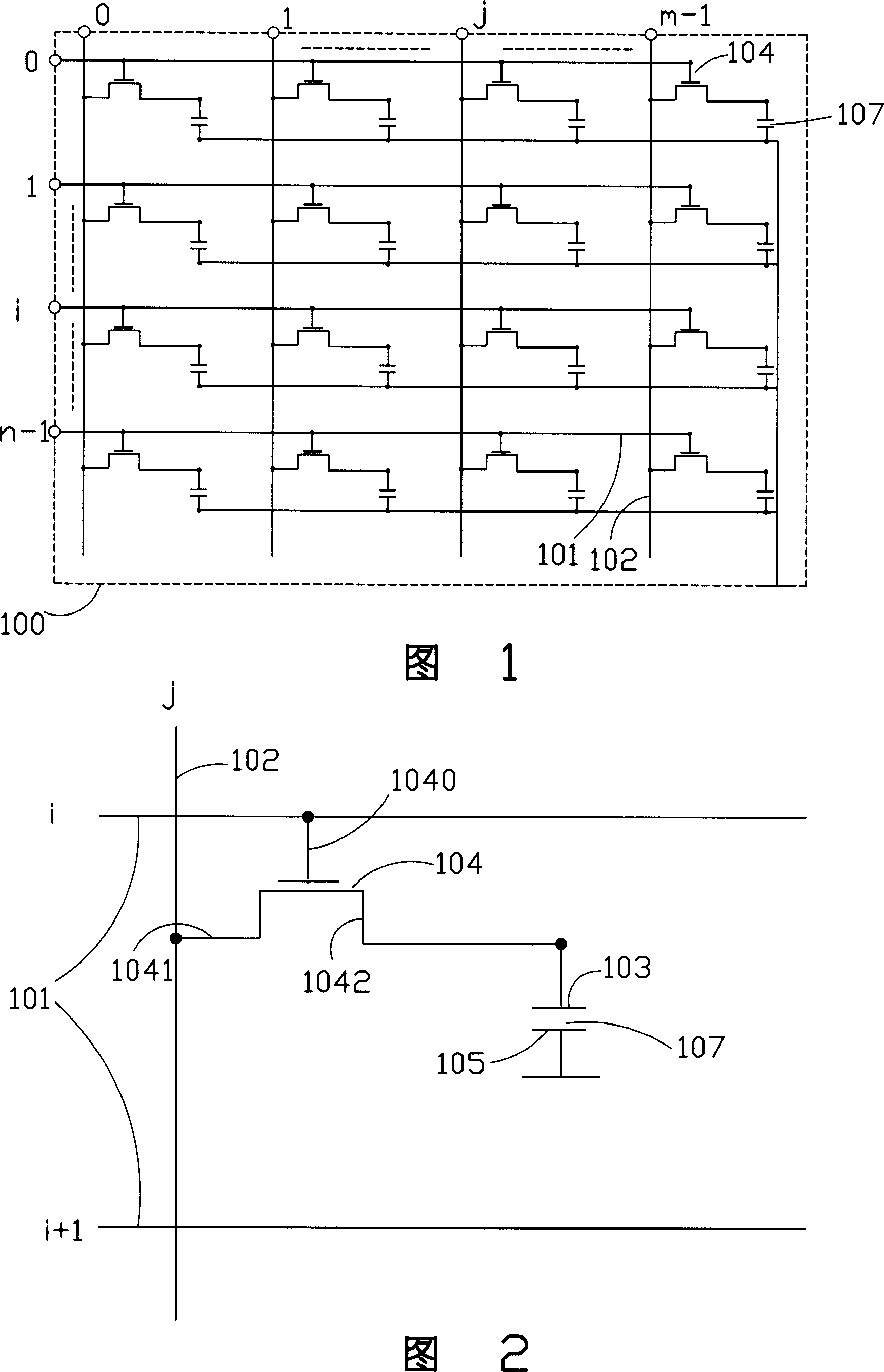

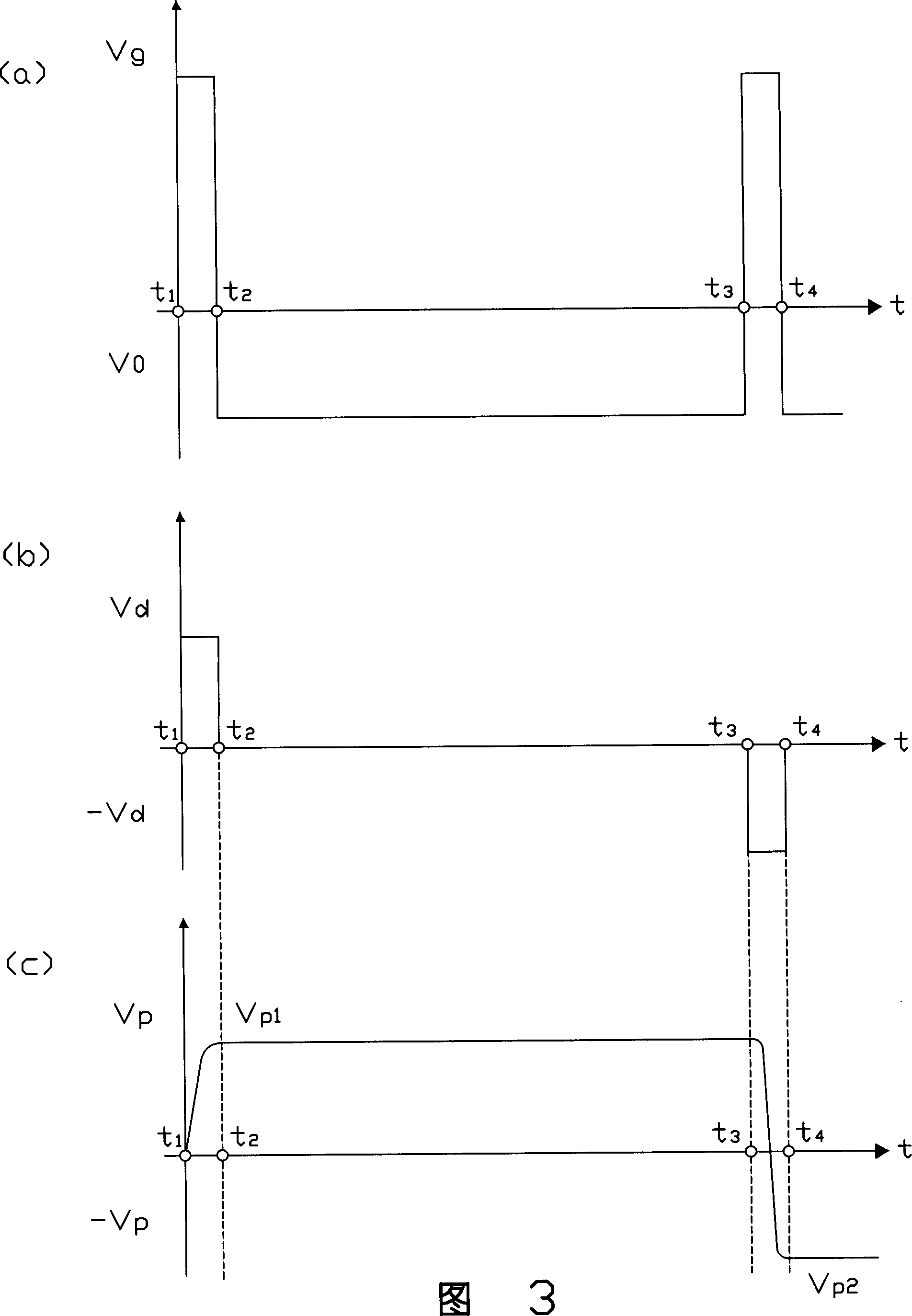

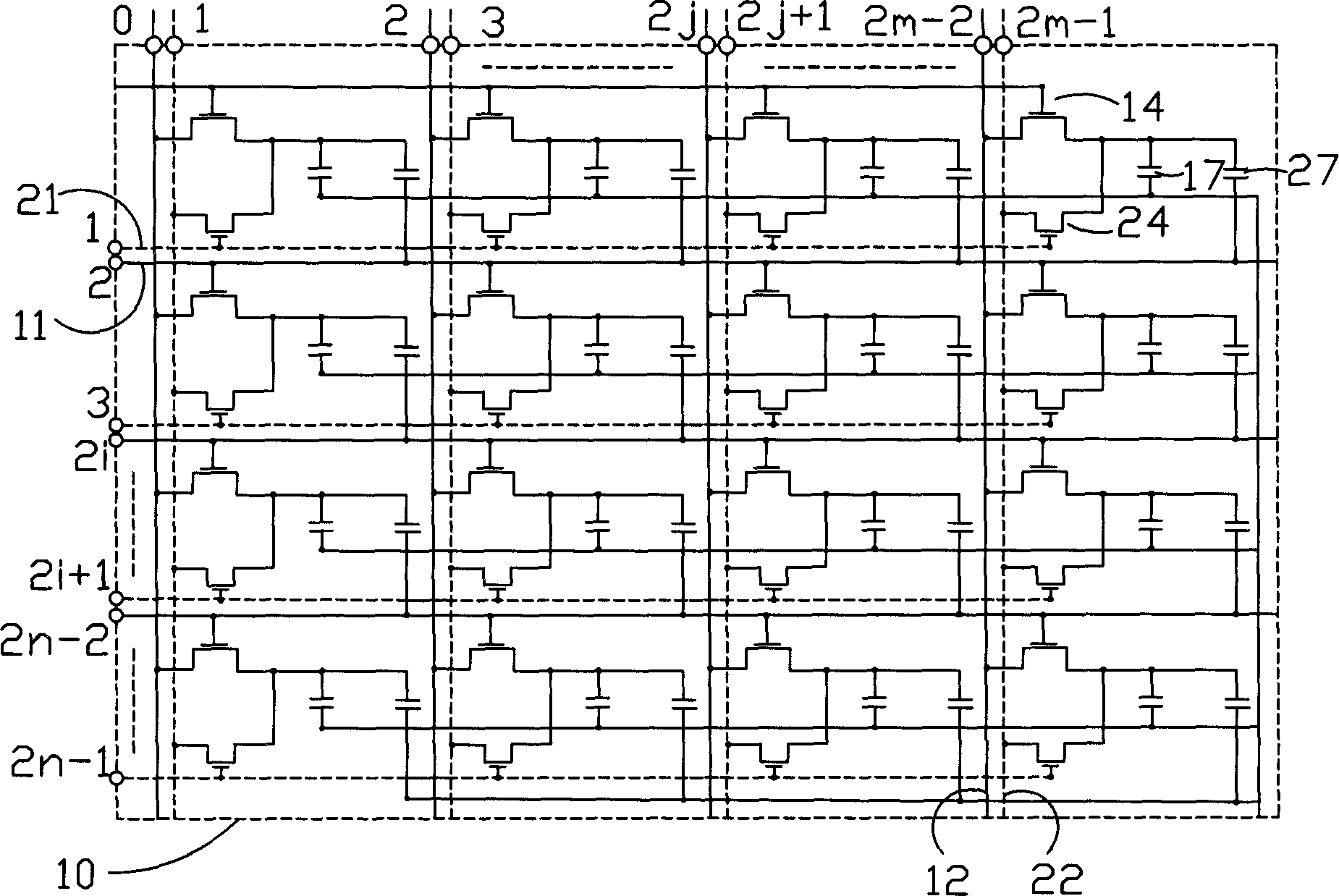

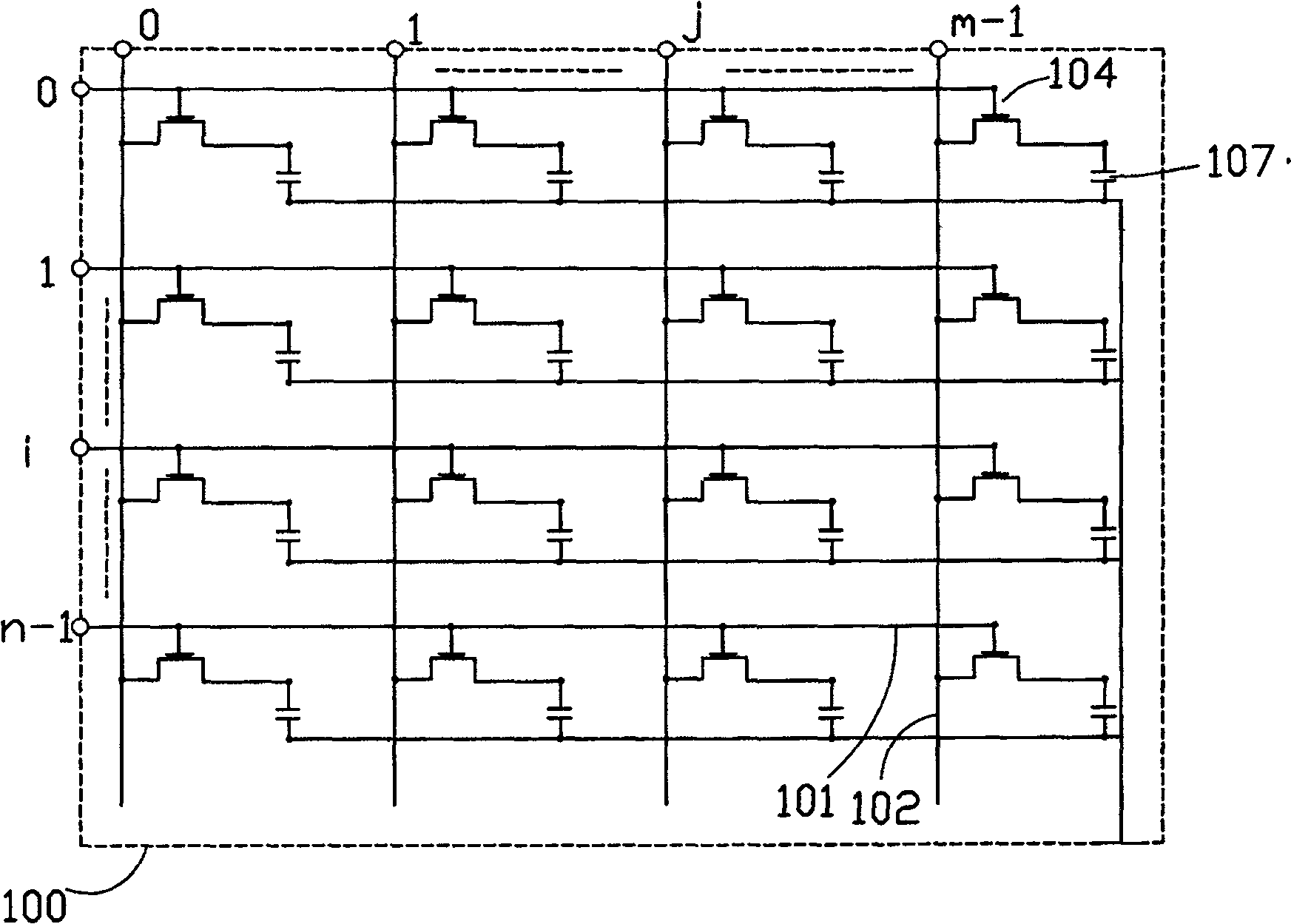

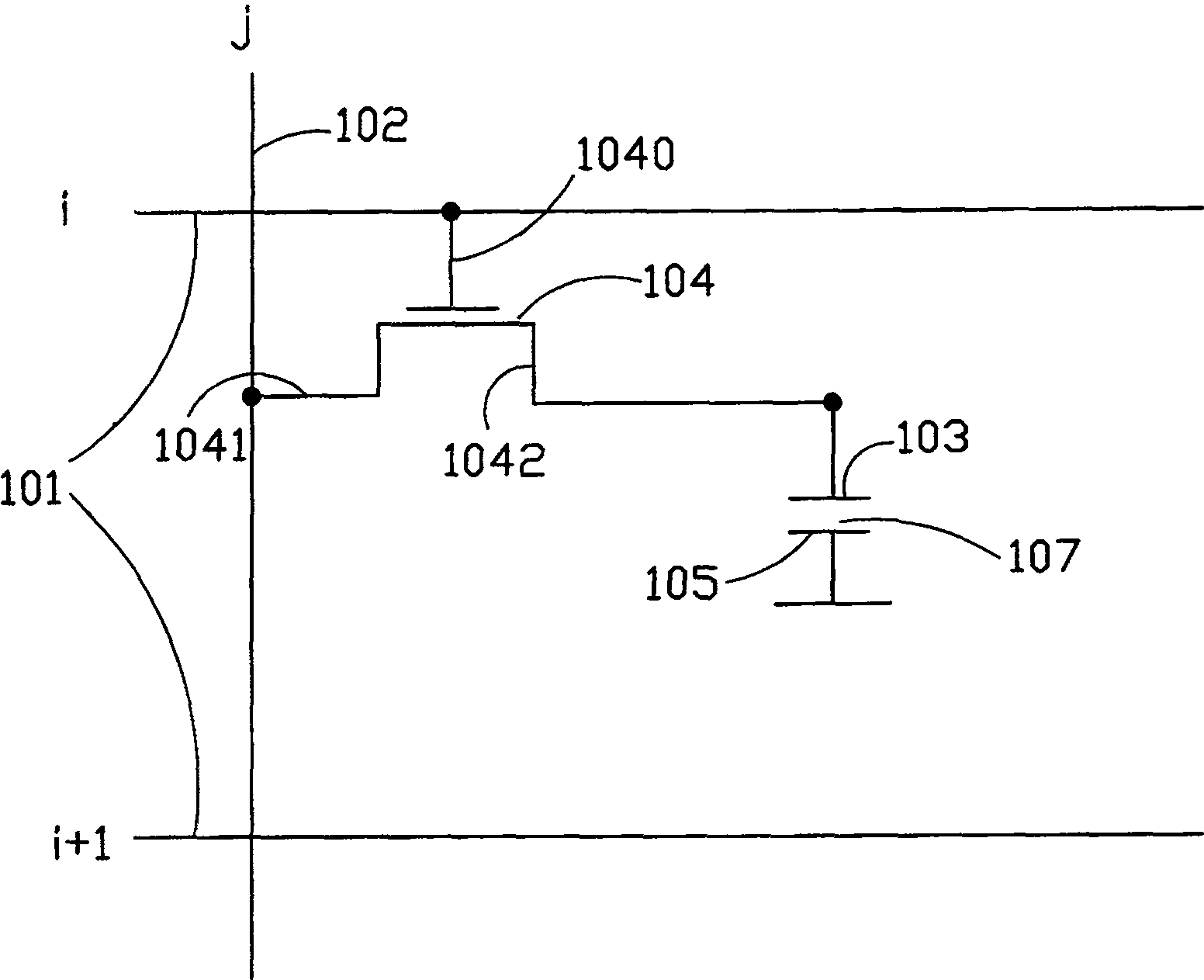

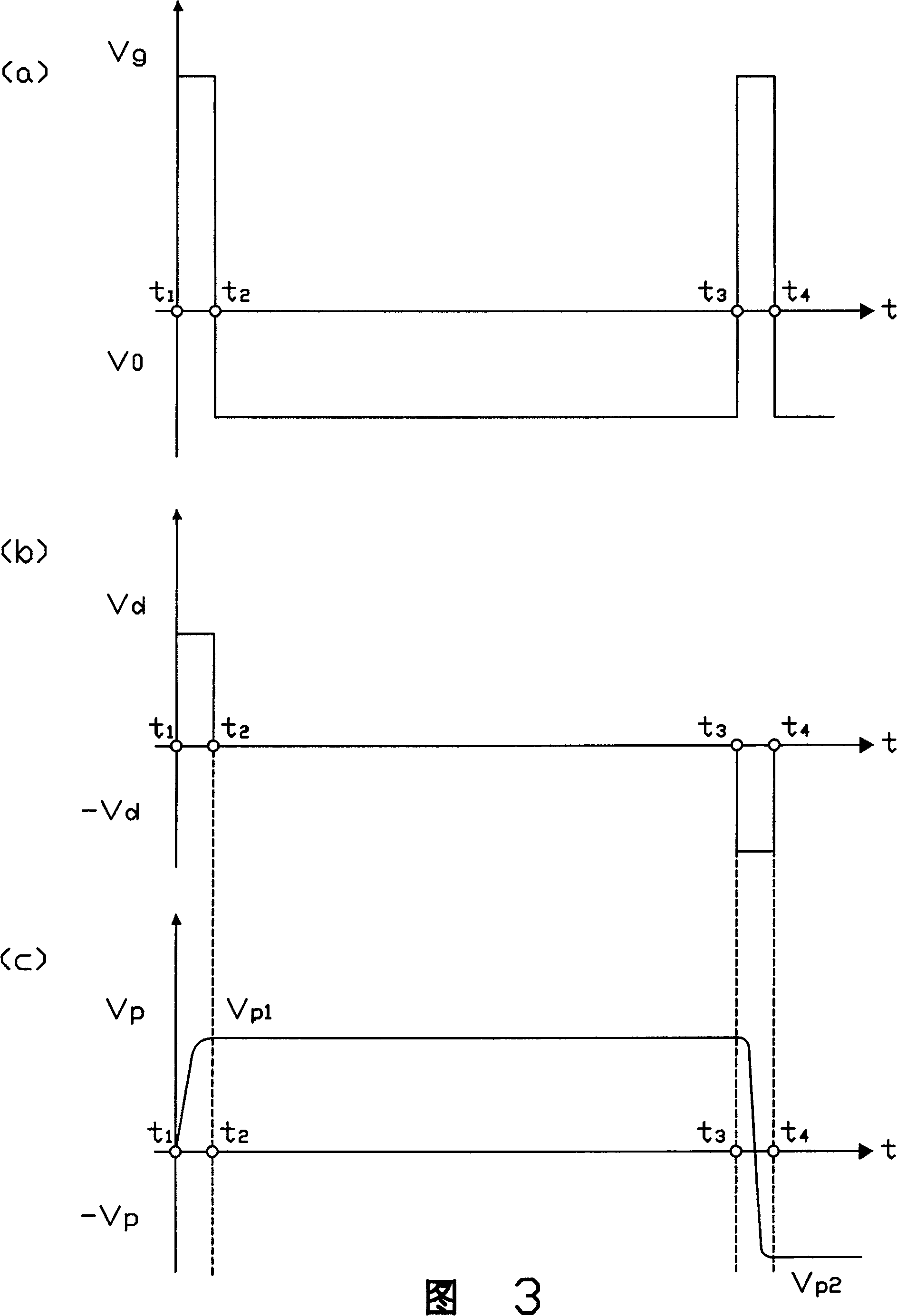

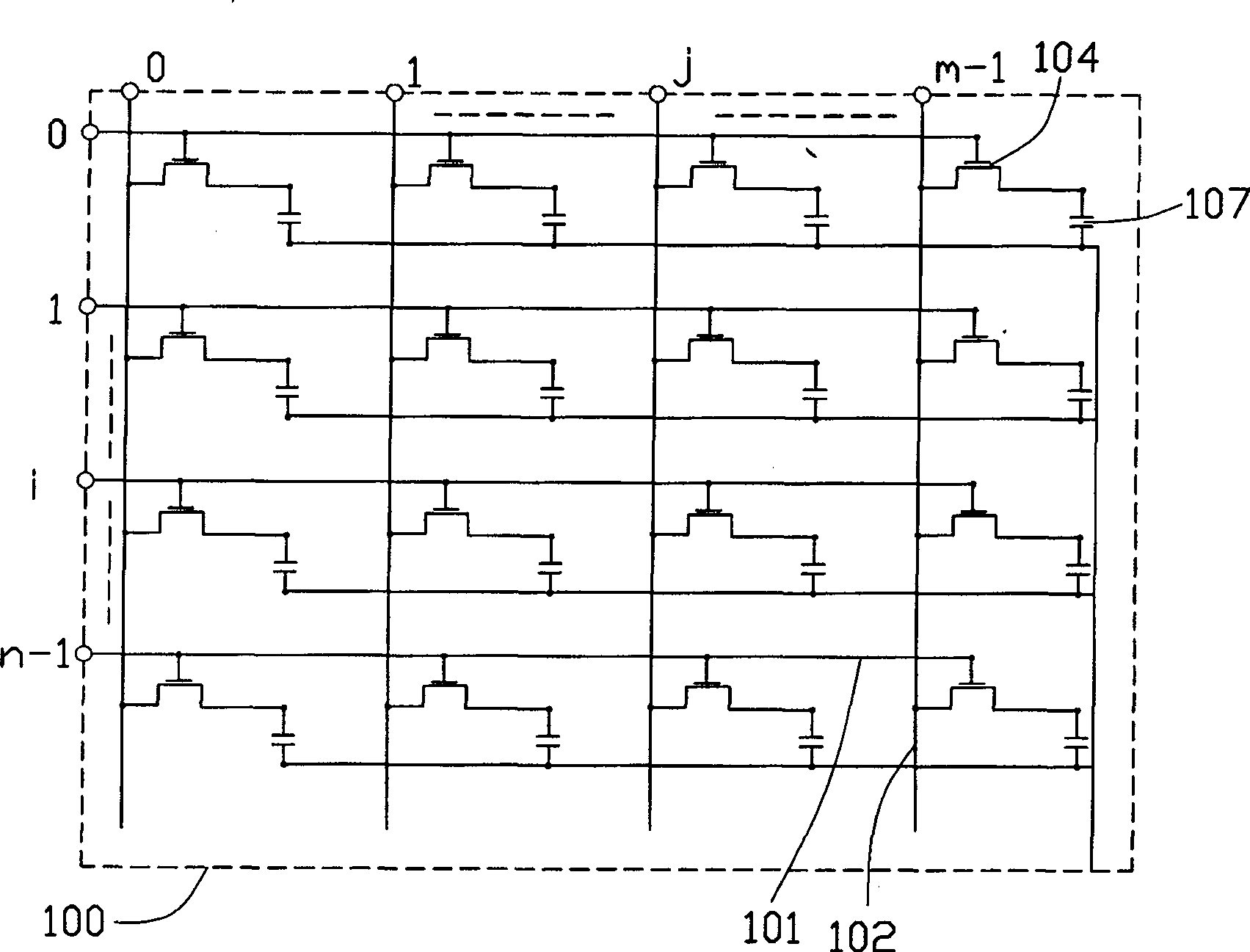

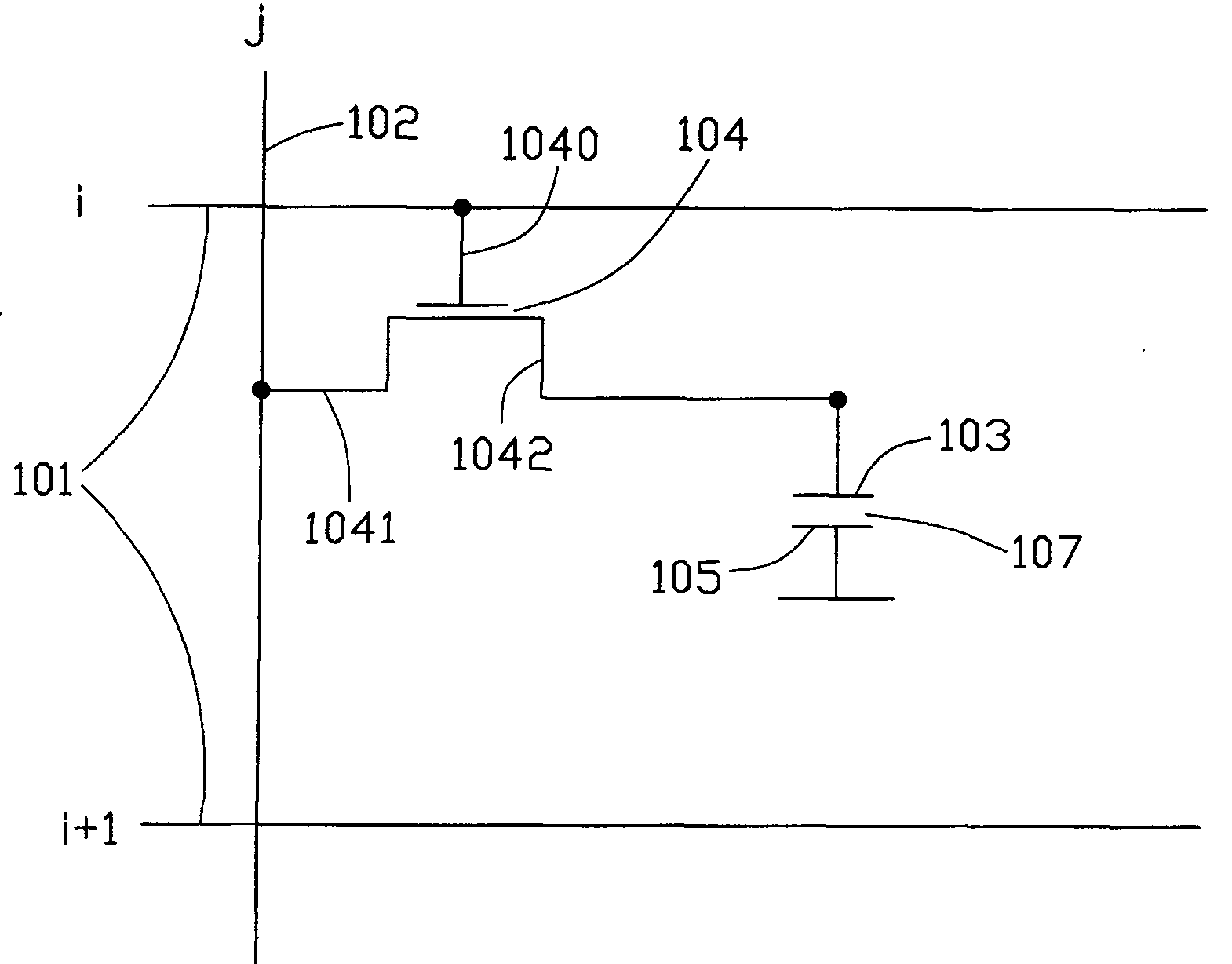

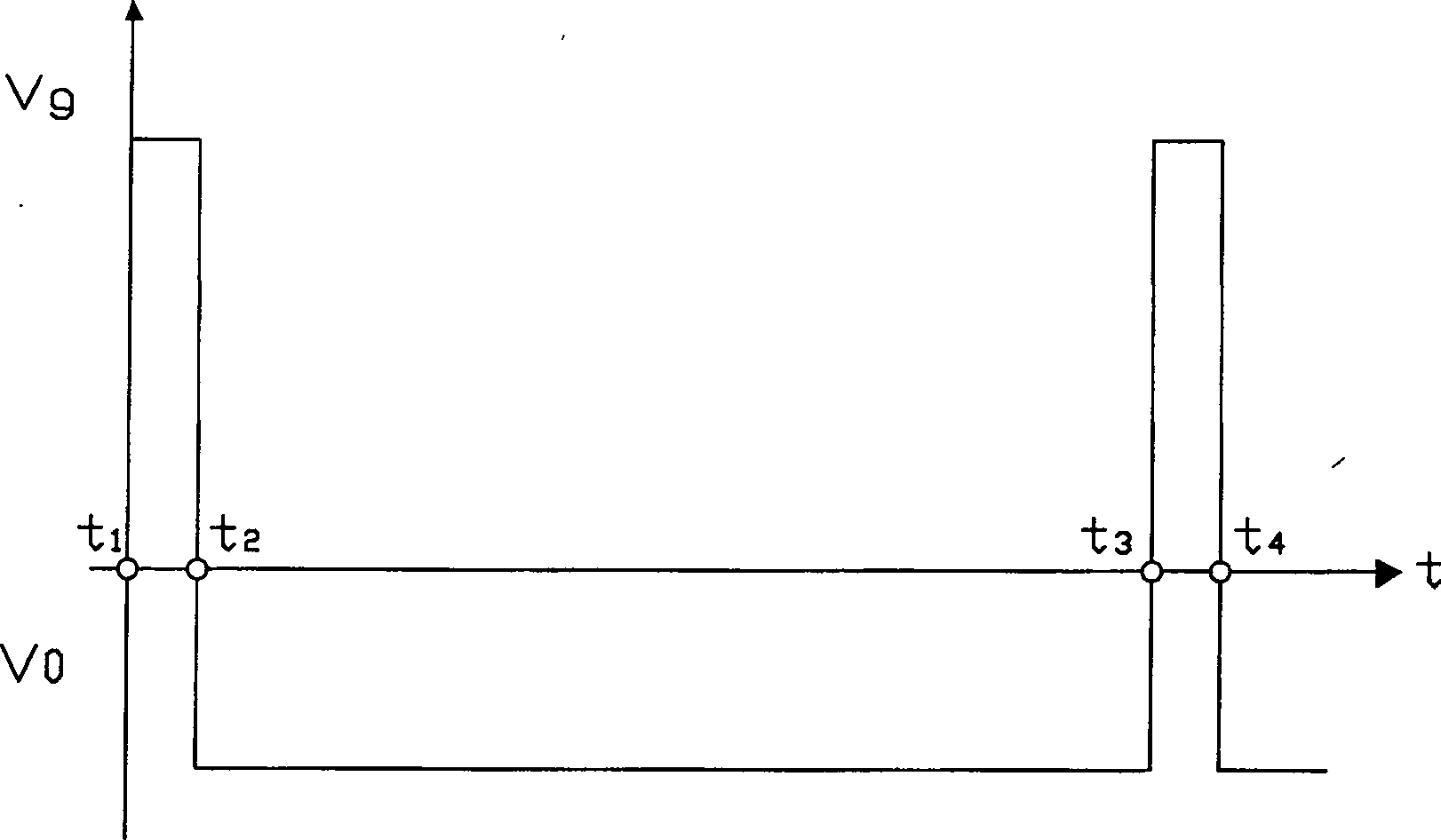

Active matrix liquid crystal display panel driving method

InactiveCN1581274ARapid responseNo blurringTransistorStatic indicating devicesActive-matrix liquid-crystal displayEngineering

In the invention, one display unit possesses structure of two thin film transistors (TFT). First scanning voltage is provided for multiple first scanning lines to drive grids of multiple first TFTs. First signal voltage provided on multiple first signal lines is utilized to drive source poles of multiple TFTs. second signal voltage provided on multiple second scanning lines is utilized to drive grids of multiple second TFTs. Second signal voltage provided on multiple second signal lines is utilized to drive sources of multiple second TFTs. moment of providing second scanning voltage and second signal time is identical to or delayed to moment of providing second scanning voltage and second signal time.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

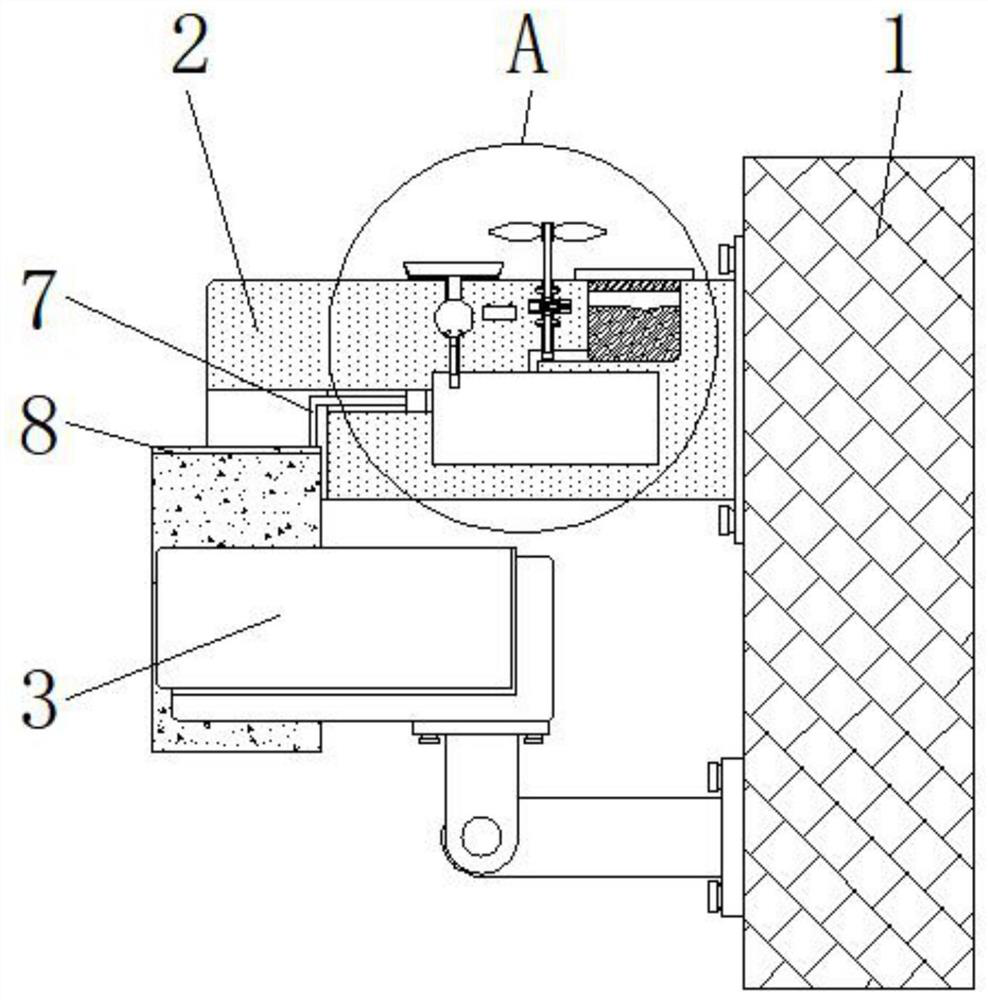

Rainproof shielding structure of building outer wall monitoring equipment

InactiveCN112055144AEnsure safetyNo blurringTelevision system detailsColor television detailsArchitectural engineeringStructural engineering

Owner:闫海滨

Active matrix liquid crystal display panel driving method

InactiveCN100437718CRapid responseNo blurringTransistorStatic indicating devicesActive-matrix liquid-crystal displayTransistor

In the invention, one display unit possesses structure of two thin film transistors (TFT). First scanning voltage is provided for multiple first scanning lines to drive grids of multiple first TFTs. First signal voltage provided on multiple first signal lines is utilized to drive source poles of multiple TFTs. second signal voltage provided on multiple second scanning lines is utilized to drive grids of multiple second TFTs. Second signal voltage provided on multiple second signal lines is utilized to drive sources of multiple second TFTs. moment of providing second scanning voltage and second signal time is identical to or delayed to moment of providing second scanning voltage and second signal time.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

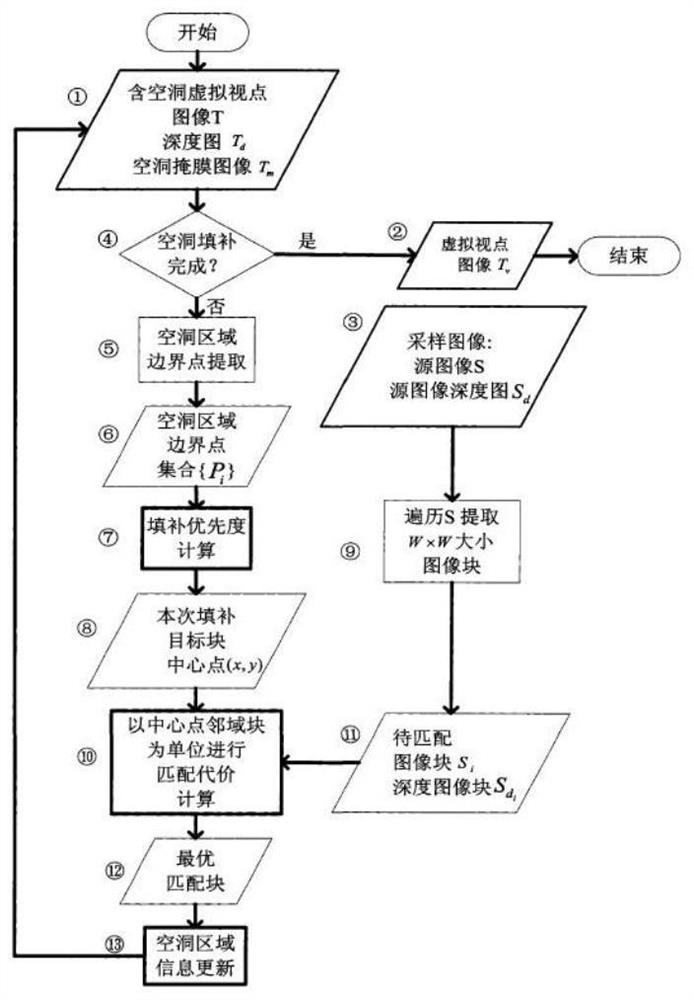

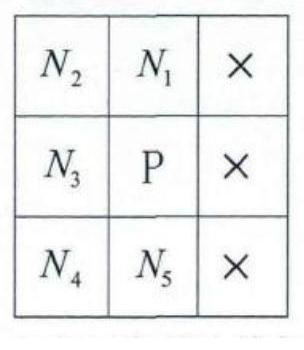

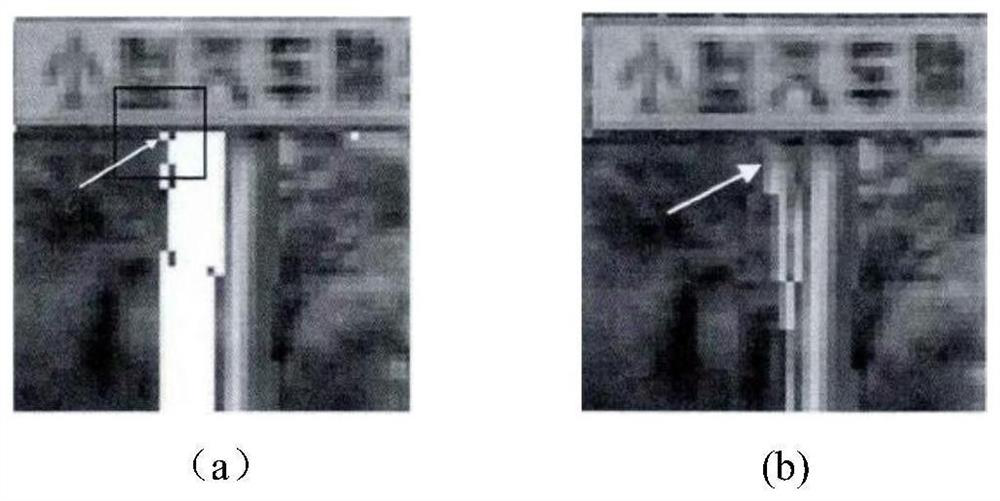

Hole filling method for converting 2D video into 3D video

PendingCN114679579AGuaranteed filling qualityImprove visual consistencySteroscopic systemsPattern recognitionColor image

The invention discloses a hole filling method for converting a 2D video into a 3D video, and the method comprises the following steps: S1, inputting a virtual viewpoint containing a hole, a corresponding depth map and other information, outputting a virtual viewpoint image after the hole is filled, and judging whether the hole is processed or not; s2, extracting boundary points of a cavity region when the cavity is not processed; and traversing all cavity points to obtain a cavity region boundary point set. S3, traversing an information source image, and extracting a matching block; and S4, calculating the matching cost of the cavity color image and the depth image target block of the central point and the to-be-matched block of the source image. And S5, obtaining an optimal matching block center point, and updating the void image through the neighborhood block source image and the depth image point of the optimal matching block center point. Through the steps, the hole filling quality can be effectively ensured, the visual consistency of virtual viewpoint synthesis is improved, and the result is enabled to be as real as possible to be close to an original image.

Owner:北京华录新媒信息技术有限公司

Spatial variation correction method for high squint SAR subaperture imaging based on two-stage filtering

ActiveCN108490441BAchieving unified calibrationNo blurringRadio wave reradiation/reflectionTime domainEnvelope (radar)

Owner:XIDIAN UNIV

A computer projection device

A computer projection apparatus includes an electrical machine, a Curtain, a support frame I, computers, a transmission line, a Control switch, a Table top, a support II, a processing system, a Tableleg and a foot cup, the motor is secured to the curtain, A support frame I and a support frame II are fixedly arranged on the desktop, the curtain is fixed on the desktop through a support frame I anda support frame II, the computers and the control switches are placed on the desktop, the transmission lines are embedded in the desktop, the Computers are connected together by control switches, theFour legs are fixedly mounted on the bottom surface of the table top, At the end of the leg of the table, A treatment system is fixedly mount on the legs of the table, The device can be projected indifferent places without the limitation of the region, and the projected image quality will not appear the phenomenon of virtual shadow or blur, and the device can be moved to the required place according to the actual needs of people, which greatly saves time, improves the utilization rate of the computer projection function, and enlarges the use range in the field.

Owner:徐州国宏文化科技有限公司

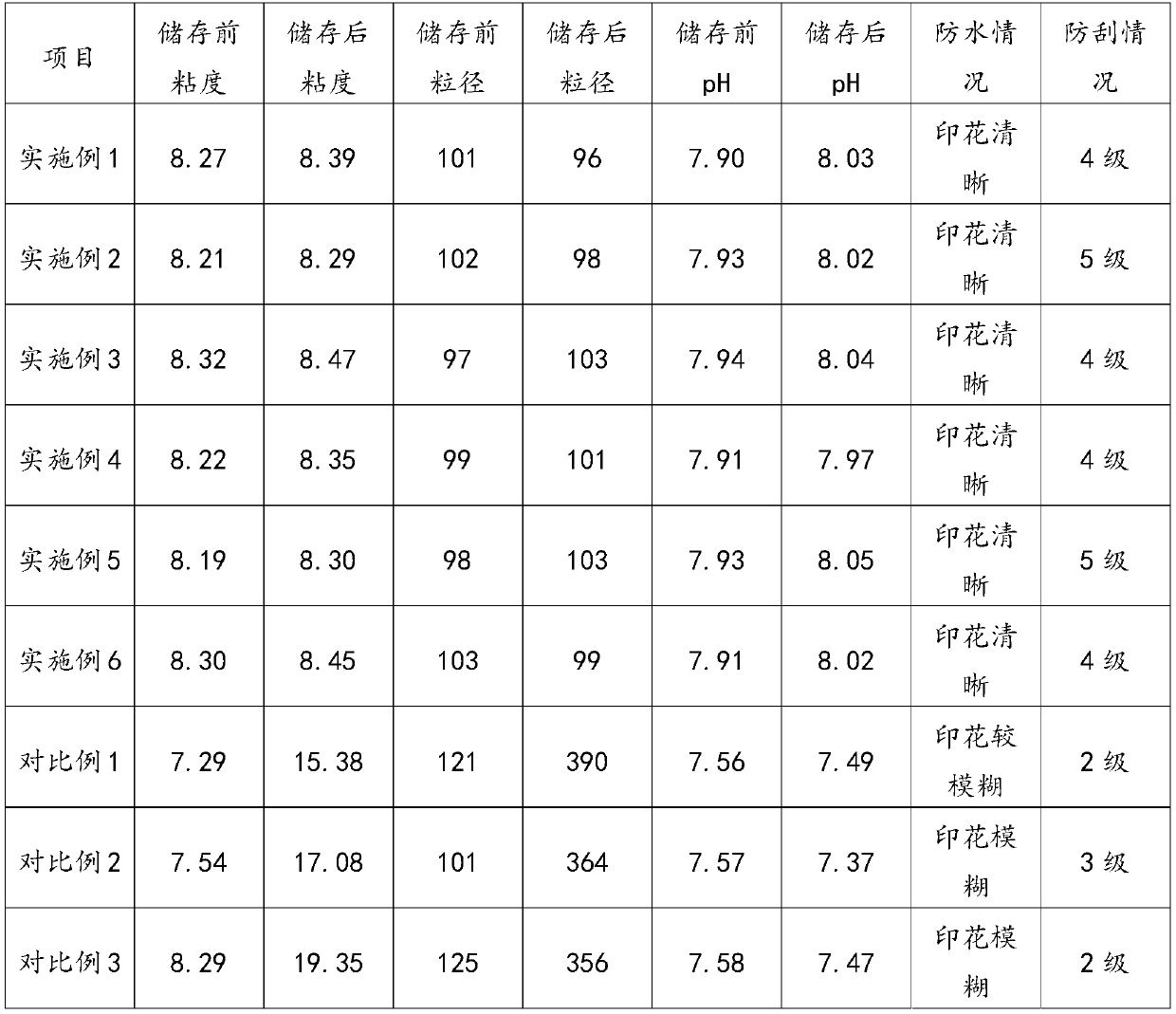

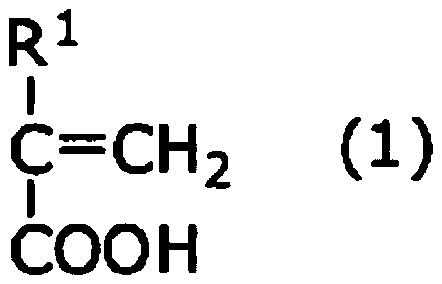

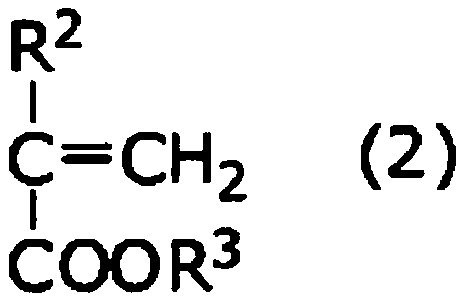

Pigment ink and preparation method thereof

The invention belongs to the field of printing consumables, and discloses a pigment ink. The pigment ink is prepared from, by weight, 1-30 parts of a color paste, 5-20 parts of a humectant, 0.1-10 parts of a surfactant, 3-15 parts of resin and 30-85 parts of water. A dispersant containing an acrylic polymer and a modified polyether copolymer is adopted to effectively disperse a toner in order to form the stable color paste, and the color paste and the resin have a good fusion effect, and coact with the surfactant, the humectant and the like, so the prepared pigment ink has good stability and scratch resistance, is a water-based pigment, but is high in waterproofness. The pigment ink is high in stability, and the viscosity and the pH value of the pigment ink are slightly changed after the pigment ink is stored at 60 DEG C for one month. When the pigment ink is used for printing, the definition is high, and the pattern is clear and no blurring phenomenon exists after the printing is soaked in water for 5 min, so the waterproofness is high.

Owner:珠海东昌色彩科技有限公司

An image acquisition device based on vehicle recognition system technology

ActiveCN111447349BPrevent moistureAvoid damageTelevision system detailsColor television detailsOptical axisEngineering

The invention provides an image acquisition device based on vehicle recognition system technology, which includes a housing, a camera installation part is provided at the front end of the housing, a shielding plate is provided at the upper end of the housing, and a support rod is provided at the bottom of the housing; There is a high-definition camera, a supplementary light and a protective cover arranged around the high-definition camera; the high-definition camera is electrically connected to an integrated board, and the integrated board is electrically connected to a heat dissipation device arranged at the rear end of the housing. The heat dissipation device includes a cooling fan, and the cooling fan is fixedly connected to a One end of the electric rotating rod, the other end of the electric rotating rod is movably connected to the bearing, and the bearing is fixedly connected to one side of the housing; the lens of the high-definition camera is equipped with a first lens and a second lens in sequence along the optical axis from the object side to the image side and third lens. The image acquisition device of the present invention can effectively and stably carry out large-scale recognition and adjustment of vehicles, and has multiple functions such as moisture-proof, rain-proof, sunshade and heat dissipation, and is convenient to use and very practical.

Owner:上海开祥信息科技有限公司

Actively driven liquid crystal display panel and driving method thereof

The present invention relates to an actively driven liquid crystal display panel, which includes a plurality of first scanning lines, a plurality of second scanning lines, a plurality of first signal lines, a plurality of second signal lines, a plurality of scanning interconnection lines, a plurality of A first thin film transistor, a plurality of second thin film transistors, and a plurality of pixel electrodes, wherein each first scanning line is electrically connected to a second scanning line through a scanning interconnection line, and makes the connection with the second scanning line The corresponding second thin film transistors are sequentially turned on at gate turn-on timing, and the gate turn-on timing of the second thin film transistor lags behind the gate turn-on timing of the corresponding first thin film transistor. The second signal line is connected to the second thin film transistor When the gate of the transistor is turned on, a black voltage is input to restore the liquid crystal display panel to a state where no image signal is applied. The invention also relates to a driving method for actively driving a liquid crystal display panel. Compared with the prior art, the invention can make the liquid crystal display picture clear.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Method of protecting archives with red-ink handwriting from spreading and sinking in during process of papering and repairing

ActiveCN102166916BWater permeableGood water permeabilityPaperhangingPaper/cardboardHandwritingPhosphoric acid

Provided is a method of protecting archives with red-ink handwriting from spreading and sinking in during process of papering and repairing. The method comprises the steps of uniformly mixing, by mass, 1 part of phospho-tungstic acid, 2.3 to 3.9 parts of phosphoric acid, 48.8 to 52.0 parts of acetone and 2.8 to 9.2 parts of tetraeththyl orthosiliate to prepare a first reinforcing agent and coating the agent on red-ink handwritings; preparing a second reinforcing agent with 1 part by mass of ethyl cellulose, 6.25 parts by mass of barium hydroxide and 40 parts by mass of methanol and coating the agent on the red-ink handwritings coated with the first reinforcing agent; and preparing a third reinforcing agent with, by mass, 1 part of ethyl cellulose banana oil solution and 0.03 to 0.17 part of polymethylmethacrylate banana oil solution, wherein mass percentage of the ethyl cellulose banana oil solution is 4% and mass percentage of the polymethylmethacrylate banana oil solution is 4%, andcoating the third reinforcing agent on the red-ink handwritings coated with the second reinforcing agent. The method of protecting the red-ink handwritings enables improvement in tensile strength, folding strength and tearability of testing paper after dry heating aging, hydrothermal aging and ultraviolet aging tests. After the aging process, the handwritings which are reinforced by the reinforcing agents exhibit minor chromatic aberration. Pigments of the handwritings are not easy to fade and the handwritings can be durably kept.

Owner:SHAANXI NORMAL UNIV

Dyed fabric and method for its preparation

The invention provides a method for preparing dyed fabrics, comprising the following steps: obtaining tung leaves, placing them in water at 85-95°C, refluxing and extracting them to obtain tung leaf dyes; arranging the embryos in a modifier solution for Modified treatment to obtain a modified gray cloth; take another tung leaf, lay it on the modified gray cloth, arrange the modified embryo with the tung leaf in a hot press for heating Pressing, printing the tung leaf pattern on the modified gray cloth; placing the modified embryo with the tung leaf pattern in the tung leaf dye for dyeing; the dyed The above-mentioned modified embryos are arranged in a color-fixing agent solution for color-fixing treatment to obtain the product. The dyed fabric prepared by the above method has large dyeing capacity, high color fastness to washing and sun resistance.

Owner:ZHUHAI JIAN XUAN CLOTHING LTD

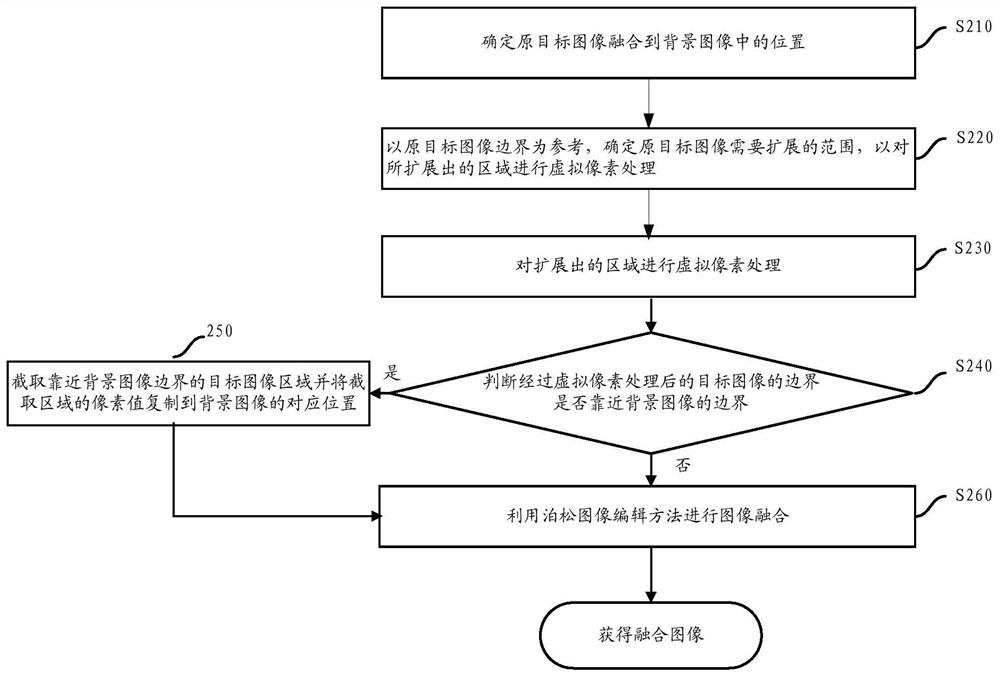

A method of image fusion

The invention provides an image fusion method. The method includes: taking the boundary of the original target image to be fused as a reference, determining the range to be extended by the boundary of the original target image; performing virtual pixel processing on the expanded range to obtain a target image after virtual pixel processing; The target image and the background image after the virtual pixel processing are fused by Poisson image editing. The image fusion method of the present invention eliminates the problems of unnatural transition of the target image and blurring at the boundary of the target image after image fusion, thereby finally obtaining an ideal image fusion effect.

Owner:北京中科晶上超媒体信息技术有限公司

A rain-proof shelter structure for monitoring equipment on the exterior wall of a building

InactiveCN112055144BEnsure safetyNo blurringTelevision system detailsColor television detailsStructural engineeringMonitor equipment

The invention discloses a rain-proof shielding structure for monitoring equipment on the outer wall of a building, which comprises a wall, a fixed block and a camera are respectively installed on one side of the wall, the fixed block is located above the camera, and the fixed block A gas chamber is opened inside, a through groove is reserved on one side of the gas chamber, a second pipe is arranged between the bottom of the first water tank and the top of the gas chamber, and a threaded plug is installed at the bottom of the second pipe , the top of the fixed block is provided with a collection basin, the bottom of the collection basin and the top of the first water tank are connected to each other through the first pipe, the inner side of the bottom of the first water tank is provided with a conductive column, and the fixed block The interior of the building is equipped with a battery, and the rain-proof and shelter structure of the monitoring equipment on the outer wall of the building can prevent the lens in front of the camera from blurring, thereby ensuring the safety performance of the monitoring equipment.

Owner:闫海滨

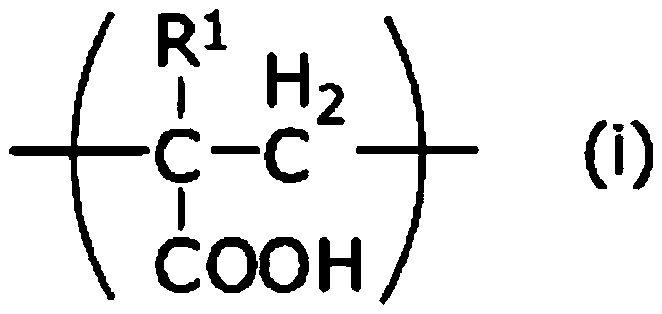

Ink composition for water-based ballpoint pen, and water-based ballpoint pen including same

To provide: an ink composition for water-based ballpoint pens which, when used in writing, gives satisfactory handwriting less apt to suffer ink running and free from blurring or line splitting and and which has excellent storage stability; and a water-based ballpoint pen including the ink composition. An ink composition for water-based ballpoint pens which comprises water, a colorant, and a copolymer having a specific structure; and a water-based ballpoint pen which includes the ink composition.

Owner:PILOT PEN CO LTD

An optical compensation type long-wave infrared continuous zoom optical system

ActiveCN105676432BLong focal lengthHigh zoom ratioCamera body detailsOptical elementsOptical axisControl system

The invention relates to an optical compensation type long-wave infrared continuous zoom optical system, which comprises a front fixed mirror group, a front moving mirror group, a middle fixed mirror group, a rear moving mirror group and a rear fixed mirror group arranged sequentially from the object side to the image side, The front moving mirror group is composed of the first moving lens and the second moving lens arranged in sequence, and the rear moving mirror group is composed of the third moving lens and the fourth moving lens arranged in sequence, and the front moving mirror group and the rear moving mirror group are on the optical axis Do front and rear linkage with equal distance, equal speed, and same direction to realize optical compensation continuous zoom. The optical compensation system has a simple structure and is easy to manufacture, and has low requirements on the precision of the control system. To overcome the disadvantage that the mechanical compensation system requires a complex cam structure or the precise cooperation of the double screw to ensure that the image remains clear during the zooming process.

Owner:凯迈(洛阳)测控有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com