High-density solid-free stagnation plug and preparation method thereof

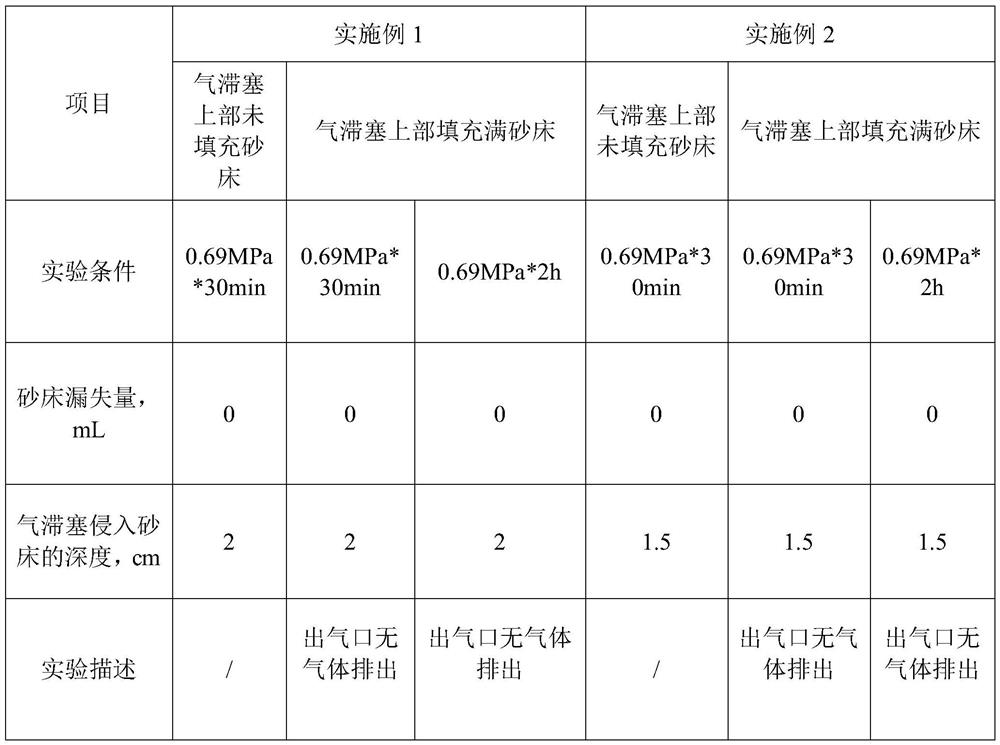

A solid-free, high-density technology, applied in the field of petroleum drilling, can solve problems such as the increase in viscosity of polysulfide drilling fluid, and achieve the effects of slowing down the upward channeling of oil and gas, ensuring construction efficiency and safety, and strong temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, only some exemplary embodiments are briefly described. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit or scope of the present invention.

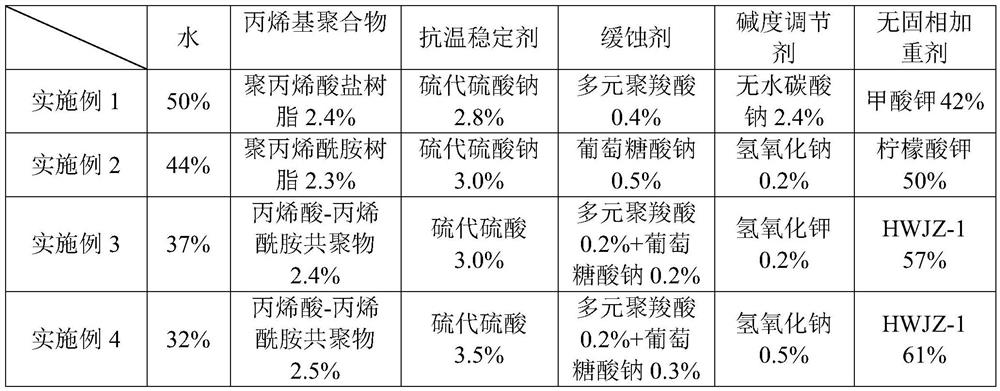

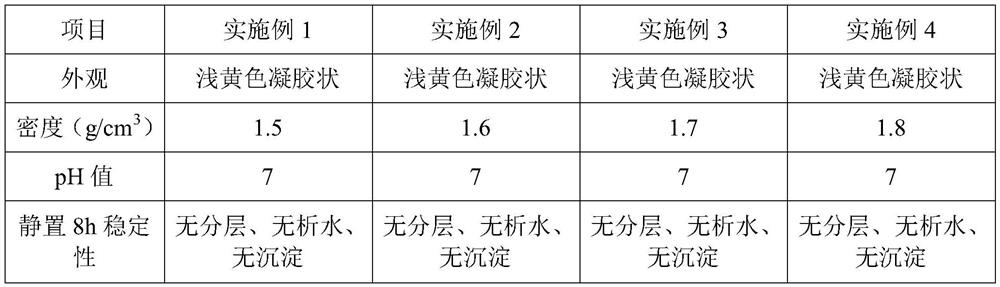

[0032] A high density non-solid gas stagnation plug, by weight and 100%, comprising the following raw materials:

[0033] Water 30%~50%,

[0034] Propylene-based polymer 2% to 5%,

[0035] Anti-temperature stabilizer 2% to 5%;

[0036] Corrosion inhibitor 0.2% ~ 0.5%,

[0037] Alkalinity regulator 0.1% ~ 3%,

[0038] No solid phase weighting agent 40-65%.

[0039] Wherein, the acrylic polymer is one or more of polyacrylic acid, polyacrylic acid salt, polyacrylamide, and acrylic acid-acrylamide copolymer. The anti-temperature stabilizer is one or more of sodium thiosulfate and thiosulfuric acid. The corrosion inhibitor is one or two kinds of polycarboxylic acid and sodium gluconate. The alkalinity regulator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com