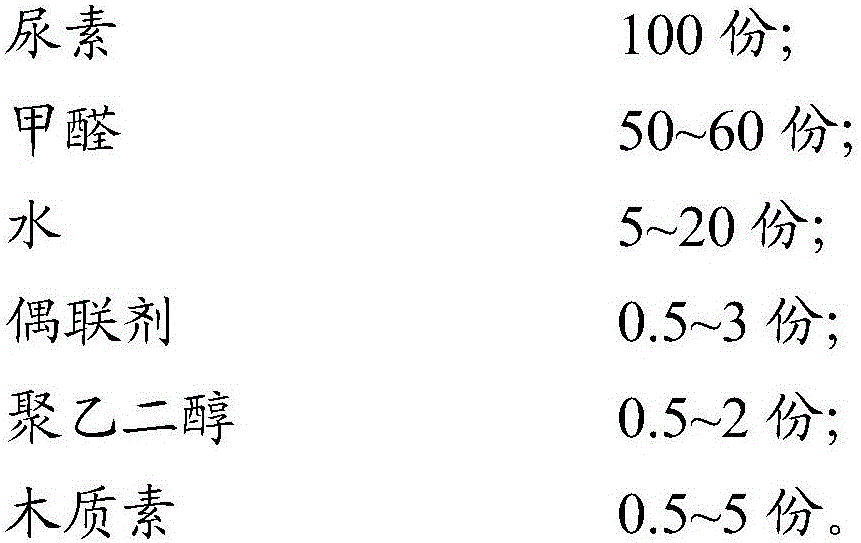

Urea-formaldehyde resin adhesive and preparation method and application thereof

A technology of urea-formaldehyde resin adhesives and adhesives, which is applied in adhesives, aldehyde/ketone condensation polymer adhesives, manufacturing tools, etc., and can solve problems such as threats to human health and the impact on the mechanical properties of bonded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a method for preparing the urea-formaldehyde resin adhesive described in the above technical solution, comprising the following steps:

[0035] After mixing formaldehyde, water, the first part of urea, a coupling agent and polyethylene glycol, a first polycondensation reaction is carried out to obtain a first polycondensate;

[0036] After adjusting the pH value of the first polycondensate to 6-6.5, mixing with the second portion of urea and lignin to perform a second polycondensation reaction to obtain a second polycondensate;

[0037] After adjusting the pH value of the second polycondensate to 7.5-8, mixing it with the remaining urea to carry out the third polycondensation reaction to obtain the third polycondensate;

[0038] adjusting the pH value of the third condensation polymer to 7-7.5 to obtain the urea-formaldehyde resin adhesive.

[0039] The present invention mixes formaldehyde, water, the first part of urea, a coupling agent ...

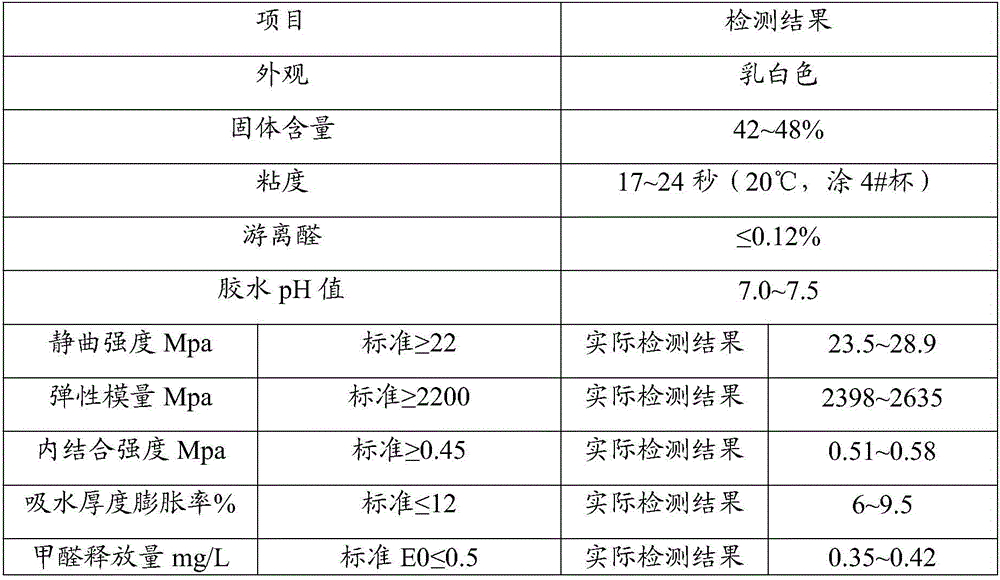

Embodiment 1

[0054] Weigh 139 parts of formaldehyde solution with a mass fraction of 37% and add it to the reaction kettle at one time, and add 15 parts of water to adjust the pH value to 8.5. For the first time, add 55.5 parts of urea with a purity of 98%, and then add 3 parts of KH550 And 2 parts of polyethylene glycol (400), open the steam and stir to heat up.

[0055] The temperature of the reaction kettle was raised from below 50°C, and after 40 minutes of heating, the temperature was raised to 90°C, and the reaction was kept at 90°C for 30 minutes. After the holding time expires, under the condition that the temperature is kept at 90°C, first adjust the pH value to 5.8, then adjust the pH value to 5.0 after 10 minutes, and then adjust the pH value to 4.7 after another 8 minutes. Test the viscosity, when the viscosity reaches 16S (25°C, apply 4# cup), adjust the pH value to 6.2, add 21.5 parts of urea with a purity of 98% for the second time, and add 3 parts of ground wood lignin, rea...

Embodiment 2

[0062] Weigh 150 parts of formaldehyde with a mass fraction of 37% and add it to the reactor at one time, and add 5 parts of water to adjust the pH value to 8.8. For the first time, add 55.5 parts of urea with a purity of 98%, and then add 2 parts of KH560 and 1.5 parts of polyethylene glycol (400), turn on the steam and stir to raise the temperature.

[0063] The temperature of the reaction kettle was raised from below 50°C, and after 45 minutes, the temperature was raised to 95°C, and the reaction was kept at 95°C for 30 minutes. After the holding time is up, under the condition that the temperature is kept at 95°C, first adjust the pH value to 6.0, then adjust the pH value to 5.1 after 10 minutes, and then adjust the pH value to 4.5 after another 10 minutes. Test the viscosity, when the viscosity reaches 16.5S (25°C, apply 4# cup), adjust the pH value to 6.5, add 21.5 parts of urea with a purity of 98% for the second time, and add 3 parts of corncob lignin, and react for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Internal binding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com