High-speed steel convectional cooling annealing pipe

A technology for convective cooling and annealing tubes, which is applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., and can solve the problems of inconvenient sealing of tubes and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

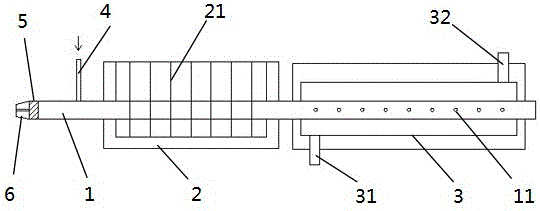

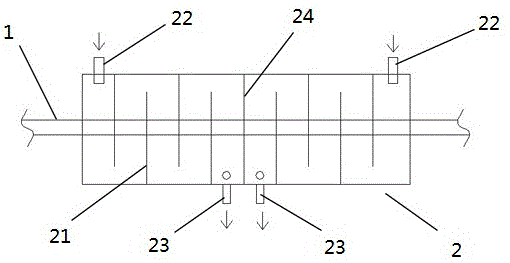

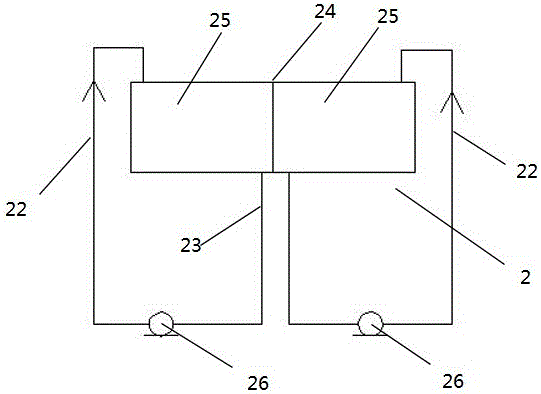

[0024] Embodiment 1: A high-speed steel convective cooling annealing tube, the high-speed steel convective cooling annealing tube includes an annealing tube main body; the annealing tube main body is sequentially provided with a combustion chamber and a water bath along the high-speed steel movement direction; the water bath There is a baffle in the center of the water bath to divide the water bath into two sub-water baths that are not connected to each other; each end of the water bath is provided with an inlet pipe; A water outlet pipe; each of the sub-water baths is provided with a circulating water pump, and a relatively flowing cooling water flow is formed in the water bath through the circulating water pump; the water in the water bath flows over the annealing tube body;; the annealing tube body The pipe section arranged in the combustion chamber is provided with a plurality of gas holes on both sides in the horizontal direction; the combustion chamber is provided with an ...

Embodiment 2

[0026] Embodiment 2: A high-speed steel convective cooling annealing tube, the high-speed steel convective cooling annealing tube includes an annealing tube body; the annealing tube body is sequentially provided with a combustion chamber and a water bath along the high-speed steel movement direction; the water bath There is a baffle in the center of the water bath to divide the water bath into two sub-water baths that are not connected to each other; each end of the water bath is provided with an inlet pipe; A water outlet pipe; each of the sub-water baths is provided with a circulating water pump, and a relatively flowing cooling water flow is formed in the water bath through the circulating water pump; the water in the water bath flows over the annealing tube body;; the annealing tube body The pipe section arranged in the combustion chamber is provided with a plurality of gas holes on both sides in the horizontal direction; the combustion chamber is provided with an igniter; t...

Embodiment 3

[0028] Embodiment 3: A high-speed steel convective cooling annealing tube, the high-speed steel convective cooling annealing tube includes an annealing tube main body; the annealing tube main body is sequentially provided with a combustion chamber and a water bath along the moving direction of the high-speed steel; the water bath There is a baffle in the center of the water bath to divide the water bath into two sub-water baths that are not connected to each other; each end of the water bath is provided with an inlet pipe; A water outlet pipe; each of the sub-water baths is provided with a circulating water pump, and a relatively flowing cooling water flow is formed in the water bath through the circulating water pump; the water in the water bath flows over the annealing tube body;; the annealing tube body The pipe section arranged in the combustion chamber is provided with a plurality of gas holes on both sides in the horizontal direction; the combustion chamber is provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com