Process for extracting tungsten by tungsten wastes

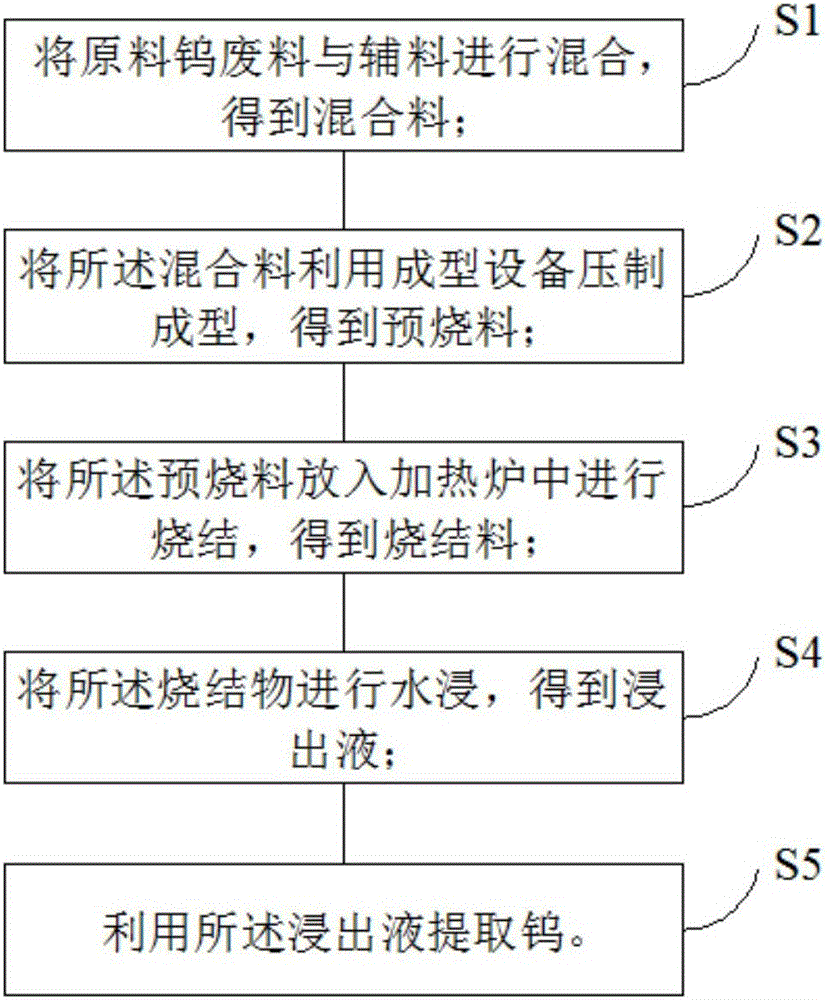

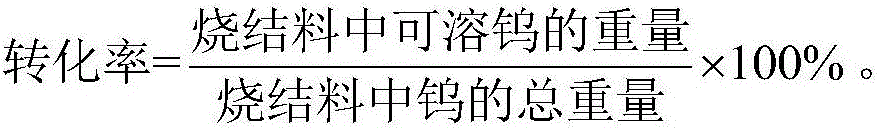

A process method and technology for tungsten waste, applied in the field of tungsten waste pressing and sintering, can solve the problems of low tungsten conversion rate, etc., and achieve the effects of high production volume, good development, high structural strength and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

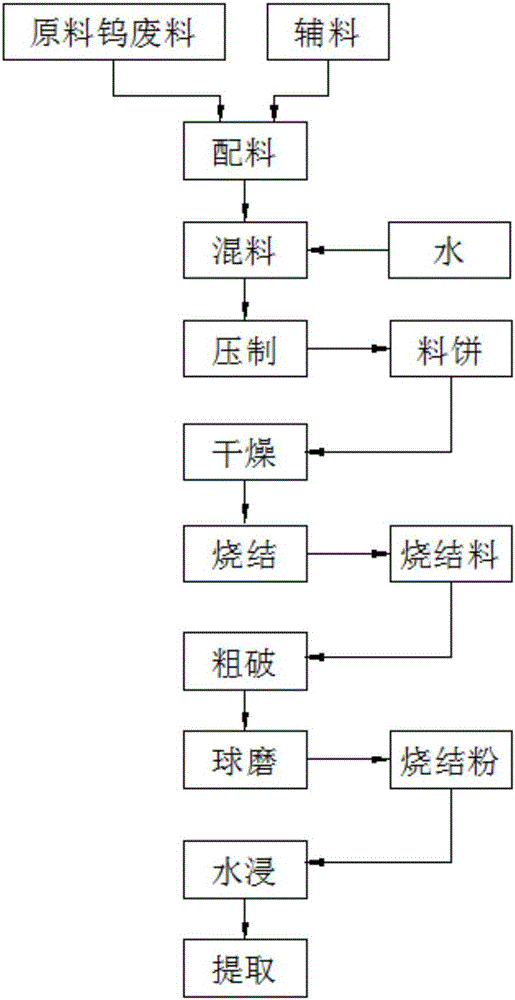

Method used

Image

Examples

Embodiment 1

[0071] 1) The proportion of ingredients is raw material: auxiliary material = 45:55. Get 100g tungsten waste material, wherein comprise the tungsten-containing catalyst of 50% (weight ratio) and the tungsten-containing grinding material of 50% (weight ratio), promptly the add-on of tungsten-containing catalyst is 50g, the add-on of tungsten-containing grinding material is 50g, so that the chemical composition of the raw material is WO 3 Accounted for 14.5%, SiO 2 41.5%, Al 2 o 3 It accounts for 24.1%, and the rest is phosphorus, arsenic, copper, chromium, cobalt, nickel, fluorine and carbon. According to WO 3 According to the stoichiometric calculation of theoretical consumption, add 4 times of soda ash to the tungsten waste, the addition coefficient of soda ash is 0.457; then add 1 times of caustic soda, the addition coefficient of caustic soda is 0.345; add 0.05 times of saltpeter again, Addition coefficient of saltpeter is 1.

[0072] 2) The raw materials and auxiliar...

Embodiment 2

[0076] 1) The proportion of ingredients is raw material: auxiliary material = 60:40. Get 200g tungsten waste material, wherein comprise the tungsten-containing catalyst of 55% (weight ratio) and the tungsten-containing grinding material of 45% (weight ratio), promptly the add-on of tungsten-containing catalyst is 110g, the add-on of tungsten-containing grinding material is 90g, so that the chemical composition of the raw material is WO 3 34.5%, SiO 2 35.1%, Al 2 o 3 It accounts for 20%, and the rest is phosphorus, arsenic, copper, chromium, cobalt, nickel, fluorine and carbon. According to WO 3 According to the stoichiometric calculation of the theoretical consumption, add 5 times of soda ash to the tungsten waste, the addition coefficient of soda ash is 0.457; then add 1 times of caustic soda, the addition coefficient of caustic soda is 0.345; add 0.05 times of saltpeter again, Addition coefficient of saltpeter is 1.

[0077] 2) The raw materials and auxiliary materials...

Embodiment 3

[0081] 1) The proportion of ingredients is raw material: auxiliary material = 50:50. Get 300g tungsten scrap, including 50% (weight ratio) of iron-containing tungsten scrap and 50% (weight ratio) of tungsten-containing abrasive, that is, the addition of tungsten-containing scrap is 150g, and the addition of tungsten-containing abrasive The amount is 150g, so that the chemical composition of the raw material is WO 3 Accounting for 25.2%, SiO 2 38.5%, Al 2 o 3 It accounts for 22.3%, and the rest is phosphorus, arsenic, copper, chromium, cobalt, nickel, fluorine and carbon. According to WO 3 According to the stoichiometric calculation of the theoretical consumption, add 4.5 times of soda ash to the tungsten waste, the soda ash addition coefficient is 0.457; then add 1 times of caustic soda, the caustic soda addition coefficient is 0.345; then add 0.05 times of saltpeter, Addition coefficient of saltpeter is 1.

[0082] 2) The raw materials and auxiliary materials are mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com