Production process of antibacterial wear-resistant decorative paper

A production process and technology for decorative paper, applied in papermaking, paper, paper coatings, etc., can solve the problems of insufficient glue viscosity, unfavorable use, insufficient wear resistance, etc., achieve high sealing, increase stability, and ensure consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

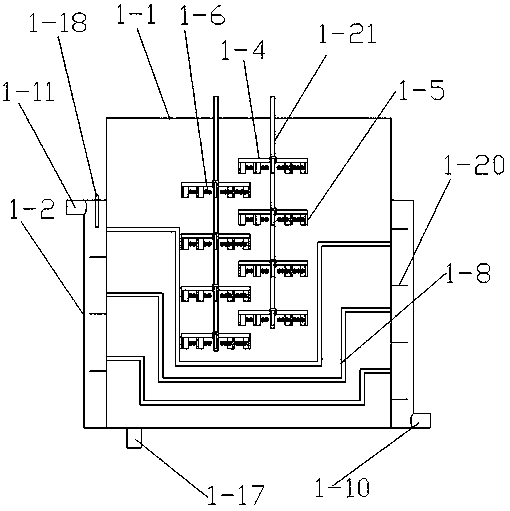

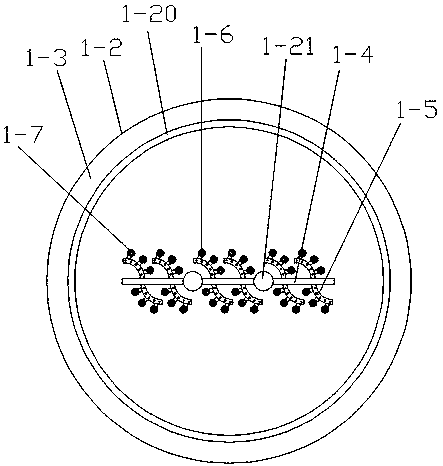

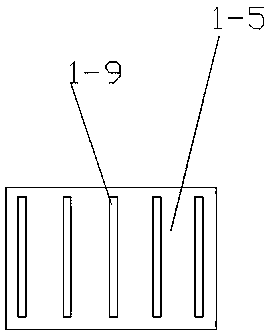

Image

Examples

Embodiment

[0043] Embodiment: antibacterial wear-resistant decorative paper production process, comprising the following steps:

[0044] 1) Preparation of urea-formaldehyde glue

[0045] a. Preheating: Clean the synthesis tank before preheating, and then preheat after cleaning. The preheating temperature rises by 2°C / min, preheats for 12-15 minutes, and keeps warm for 5 minutes;

[0046] b. Adding formaldehyde: gradually add 48 parts of formaldehyde into the synthesis tank through the feeding port, and stir to adjust the pH;

[0047] c. One-time urea injection: Add 18 parts of urea into the preheated and heat-preserved synthesis tank, the temperature rises at a rate of 1.5-2°C / min, the temperature rises to 64-65°C, slows down the heating, and the temperature rises at a rate of 0.5-1°C / min. Keep warm at 88-92°C for 30 minutes;

[0048] d. Add formic acid: During the stirring process of formaldehyde, add formic acid to adjust to PH4.2-4.8;

[0049] e. Add caustic soda and water: when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com