Assembly type architectural structure system

A building structure and prefabricated technology, used in building components, building structures, buildings, etc., can solve the problems of inability to realize industrial production, low promotion value, and difficult construction, and achieve easy on-site operation and high mold utilization. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

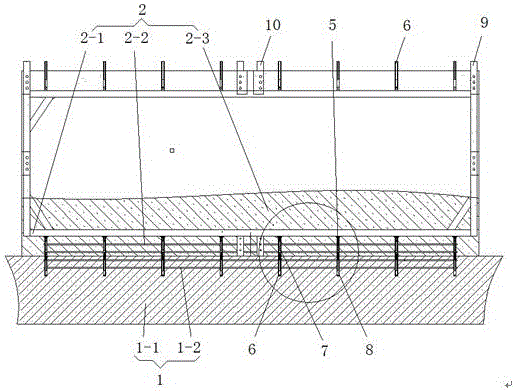

[0047] See attached picture:

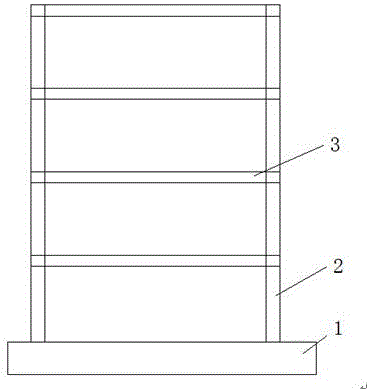

[0048] Prefabricated building structure system, including foundation 1, wall 2, floor slab 3, foundation 1 is formed by pouring reinforced concrete at the construction site;

[0049] The wall 2 is prefabricated in the factory with a steel frame structure, and the adjacent walls are "L" type A, "T" type B (two types of B1 and B2), and "┼" type C. Angle irons are used at the connection nodes connecting plate 4 connection;

[0050] The lowermost wall 2 is connected to the foundation 1, and a floor plate 5 is connected between the upper and lower walls and the top of the uppermost wall;

[0051] The floor slab 3 is in the form of a laminated floor slab, the lower 30% to 40% of the thickness direction is poured in the factory, and the upper 70% to 60% is cast in-situ at the construction site.

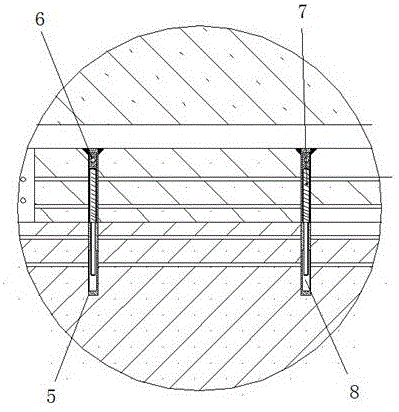

[0052] The composite connection method of grouting sleeve 5 and threaded sleeve 6 is used between the foundation 1 and the wall (the bottom wall), and betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com