Parallel-shaft type aviation gas engine

A gas engine and turboshaft engine technology, which is applied to engine ignition, engine components, gas turbine devices, etc., can solve the problems of high production cost, high exhaust gas temperature, difficult lubrication and cooling, etc., and achieve the effect of simple structure and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the embodiments and with reference to the accompanying drawings.

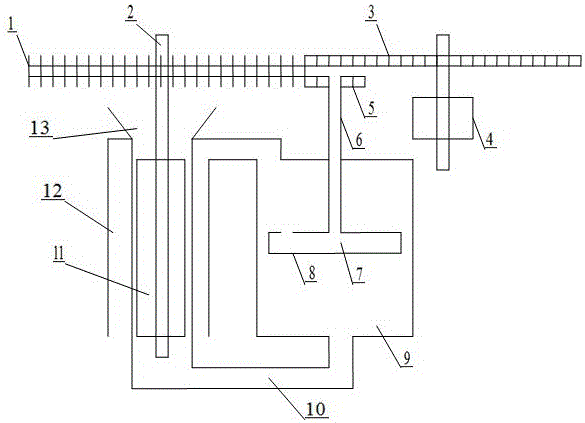

[0012] The parallel-axis aviation gas turbofan engine system of the present invention is mainly composed of a compressor and a gas turbine. The compressor consists of a first gear fan (1), a compressor shaft (2), a compressor inlet (13), a compressor machine (11), high-pressure air pipeline (10), the gas turbine is composed of work output gear (5), work output shaft (6), cooling air channel (7), free turbine (8), combustion chamber (9), the first The two-gear fan (3), the dual-purpose DC motor for starting and power generation (4) constitute the auxiliary system for starting and power generation, and the heat exchange exhaust gas channel (12) constitutes the auxiliary heat exchange system. These systems can be arranged on a plane or in a triangular shape Three-dimensional arrangement, the engine can be more compact.

[0013] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com