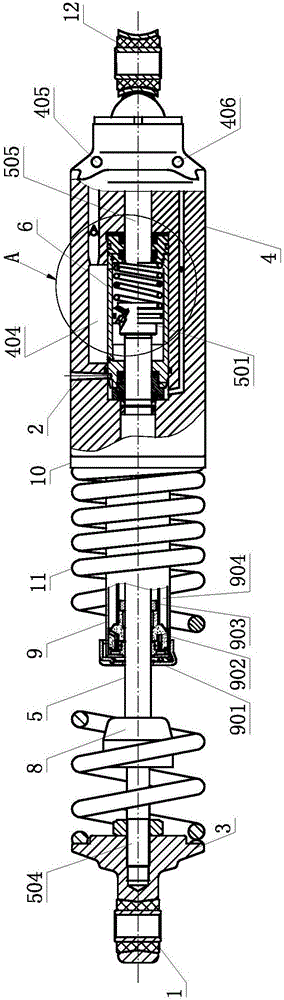

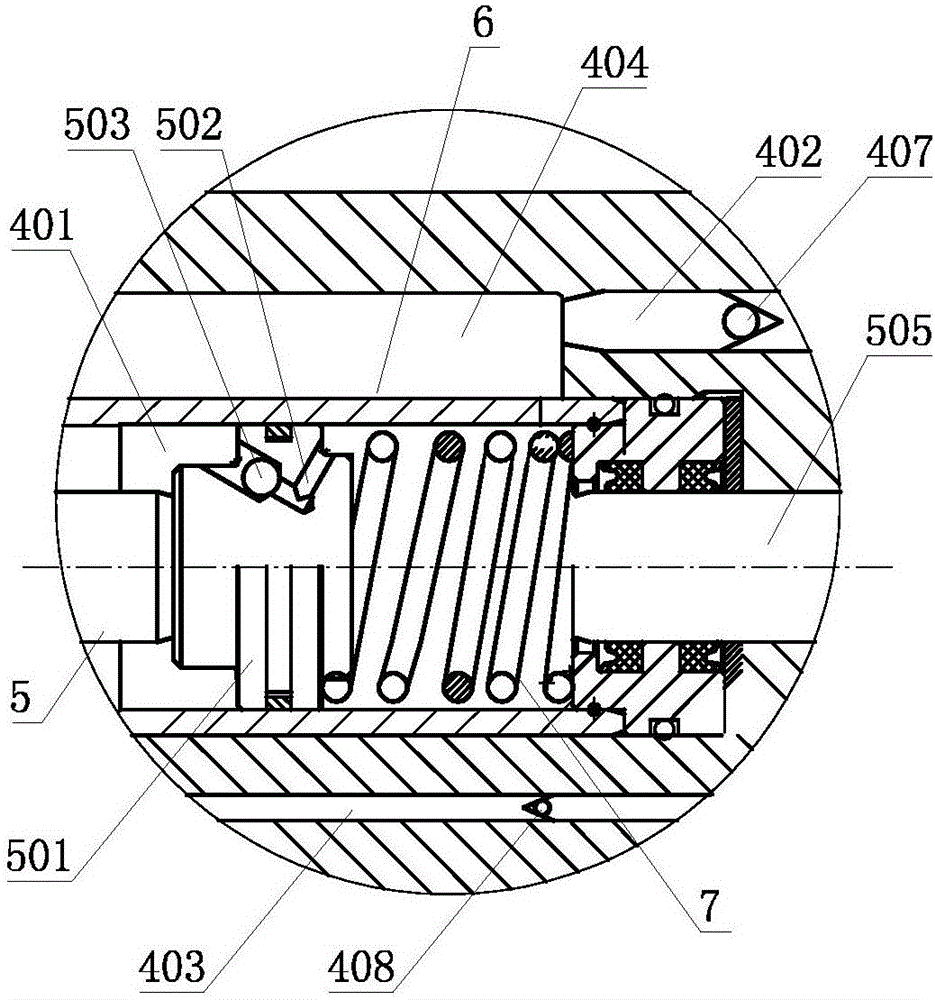

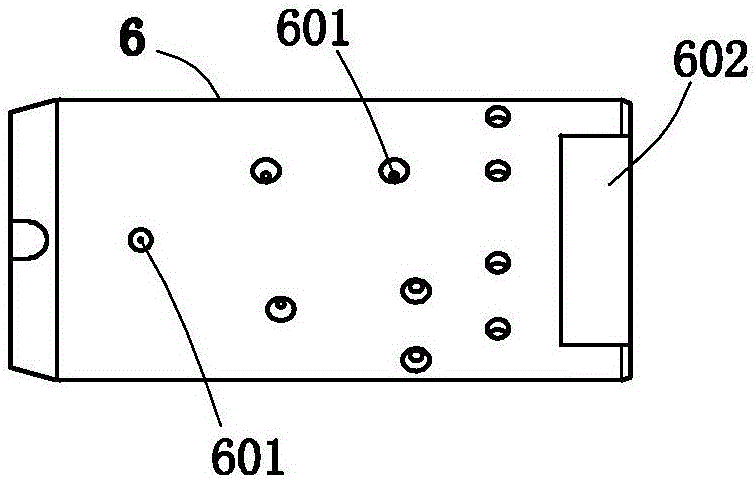

Electric vehicle damper

A technology of electric vehicles and shock absorbers, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems affecting shock absorption, etc., achieve improved performance, good damping and shock absorption, and reduce hydraulic pressure The effect of the component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0058] S1: Weigh 108 parts by mass of three-component composite elastic base material (composed of 100 parts by mass of nitrile rubber, 5 parts by mass of styrene-based thermoplastic elastomer (TPES) and 3 parts by mass of polyamide-based thermoplastic elastomer (TPAE) ), 1 part by mass of SiC whiskers with a length of 0.1-0.2mm, 2 parts by mass of dilaurate thiodipropionate, 0.1 part by mass of di-n-butyltin dilaurate, 0.3 parts by mass of ethylene-vinyl acetate copolymer ( EVA), 0.6 parts by mass of methacryloxypropyltrimethoxysilane, 1.2 parts by mass of 4,4'-diaminobicyclohexylmethane and 2 parts by mass of silicon dioxide powder with a particle size of 50-100nm;

[0059] S2: Add SiC whiskers, dilaurate thiodipropionate, ethylene-vinyl acetate copolymer (EVA), and methacryloxypropane with a total amount of 20% to the three-component composite elastic base material. Trimethoxysilane (0.12 parts by mass) and 4,4'-diaminobicyclohexylmethane (0.96 parts by mass) in a total amo...

preparation example 2

[0062]S1: Weigh 112 parts by mass of three-component composite elastic base material (composed of 100 parts by mass of nitrile rubber, 10 parts by mass of styrene thermoplastic elastomer (TPES) and 2 mass parts of polyamide thermoplastic elastomer (TPAE) ), 2 parts by mass of SiC whiskers with a length of 0.1-0.2mm, 1 part by mass of dilaurate thiodipropionate, 0.3 parts by mass of di-n-butyltin dilaurate, 0.2 parts by mass of ethylene-vinyl acetate copolymer ( EVA), 0.9 parts by mass of methacryloxypropyltrimethoxysilane, 1 part by mass of 4,4'-diaminobicyclohexylmethane and 3 parts by mass of silicon dioxide powder with a particle size of 50-100nm;

[0063] S2: Add SiC whiskers, dilaurate thiodipropionate, ethylene-vinyl acetate copolymer (EVA), and methacryloxypropane in a total amount of 30% to the three-component composite elastic base material. Trimethoxysilane (0.27 parts by mass) and 4,4'-diaminobicyclohexylmethane (0.7 parts by mass) in a total amount of 70%, and the ...

preparation example 3

[0066] S1: Weigh 110 parts by mass of three-component composite elastic base material (composed of 100 parts by mass of nitrile rubber, 7.5 parts by mass of styrene-based thermoplastic elastomer (TPES) and 2.5 parts by mass of polyamide-based thermoplastic elastomer (TPAE) ), 1.5 parts by mass of SiC whiskers with a length of 0.1-0.2mm, 1.5 parts by mass of dilaurate thiodipropionate, 0.2 parts by mass of di-n-butyltin dilaurate, 0.25 parts by mass of ethylene-vinyl acetate copolymer ( EVA), 0.8 parts by mass of methacryloxypropyltrimethoxysilane, 1.1 parts by mass of 4,4'-diaminobicyclohexylmethane and 2.5 parts by mass of silicon dioxide powder with a particle size of 50-100nm;

[0067] S2: Add SiC whiskers, dilaurate thiodipropionate, ethylene-vinyl acetate copolymer (EVA), and methacryloxypropane in a total amount of 25% to the three-component composite elastic base material. Trimethoxysilane (0.2 parts by mass) and 4,4'-diaminobicyclohexylmethane (0.825 parts by mass) in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com