Refrigerator car energy-saving environment-friendly refrigerating system based on engine waste heat recovery

A refrigeration system and waste heat recovery technology, which is applied in the direction of generator/motor, refrigerator, refrigeration and liquefaction, etc., can solve the problems of large throttling loss, high pressure and high pressure difference in refrigeration cycle, and low energy efficiency, so as to reduce oil consumption and refrigeration The effect of increased quantity and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

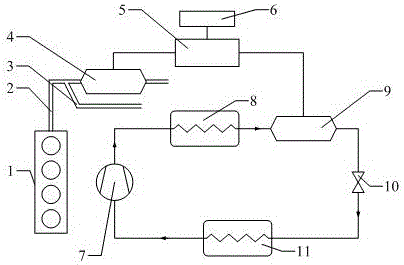

[0019] see figure 1 , is an energy-saving and environment-friendly refrigerated vehicle refrigeration system based on engine waste heat recovery and utilization, and its core is a thermoelectric power generation module and a thermorefrigeration module device. The waste heat recovery system based on the engine is mainly composed of an internal combustion engine 1, an exhaust pipe 2, a bypass pipe 3, a thermoelectric power generation module 4, a battery pack 5, and a battery management control system 6. CO 2 The refrigeration system is composed of a compressor 7 , a gas cooler 8 , a thermoelectric refrigeration module 9 , a throttle valve 10 and an evaporator 11 . The engine waste heat power generation system includes an internal combustion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com