Blackbody cavity of low-temperature radiometer

A technology of low-temperature radiation and black body cavity, which is applied in the field of optical radiation measurement, can solve the problem of low spectral absorption rate, achieve good absorption characteristics, improve thermal conductivity, and reduce uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

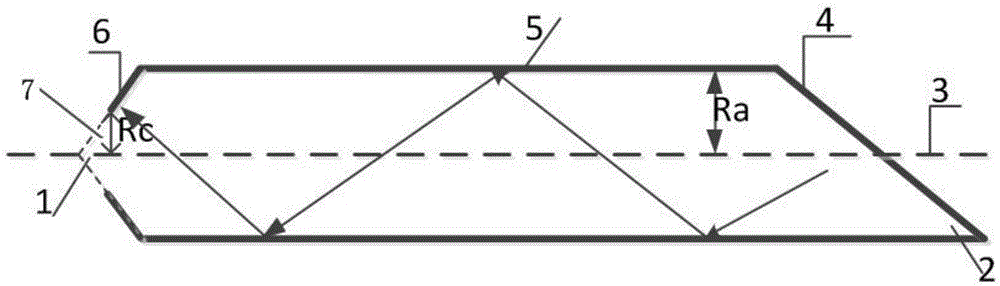

[0026] Such as figure 1 As shown, the low-temperature radiometer black body cavity of the present embodiment includes a cavity composed of a positive conical side 6, a cylindrical side 5, and an inclined bottom 4. The axis of the cone forms an angle 1 of 45°; the thin end of the right cone is provided with a cavity incident aperture 7, and the plane where the cavity incident aperture 7 is located is perpendicular to the axis 3 of the positive cone; the axis 3 between the inclined bottom surface 4 and the cylinder The angle 2 formed between them is 30°.

[0027] The positive conical side 6 forms a light-shielding design, which can be used as a diaphragm of the cavity entrance aperture 7, blocking the stray light outside the cavity from entering, and reflecting the light emitted to the exit back into the cavity again; the inclined bottom surface 4 can effectively increase the number of surface reflections; The combination of the two can effectively reduce the diffuse reflection...

Embodiment 2

[0033] This embodiment is the manufacturing method of the low temperature radiometer black body cavity of embodiment 1, comprising the following steps:

[0034] S1: A cylindrical cavity with a cavity wall thickness of 0.1 mm is produced by a precision machining process, cut at one end of the cylindrical cavity to form a cutting surface with an angle of 30° with the axis of the cylinder, and obtain the side surface 5 of the cylinder;

[0035] S2: Make a positive conical side with a cavity wall thickness of 0.1mm and an apex angle of 45°, cut at the thick end of the normal cone to obtain a cutting surface with the same diameter as the cylindrical cavity, and cut at the thin end of the normal cone to obtain a cavity with an incident diameter of 7 , to ensure that the cutting surface is perpendicular to the axis of the cone, and the side surface 6 of the right cone is obtained;

[0036] S3: according to the geometric parameters of the cylindrical cavity cutting surface, make the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com