Method for representing cohesive force between diaphragm and pole piece of lithium battery coated with polymer

A lithium battery diaphragm and polymer technology, applied in the direction of measuring devices, instruments, and mechanical devices, can solve the problems of inability to measure the size of the bonding force, poor bonding performance, and no bonding under force, and achieve detection work High efficiency, good detection repeatability, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

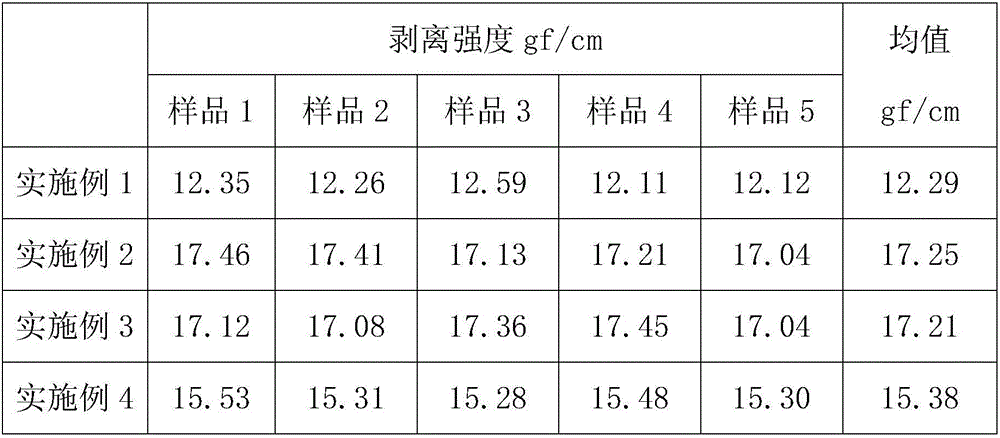

Embodiment 1

[0042] In this example, the adhesion between the PVDF coating film with a thickness of 9 μm and the pole piece is tested. The thickness of the base film is 8.5 μm, and a coating with a thickness of 0.5 μm is applied on one side. The specific operation steps are as follows:

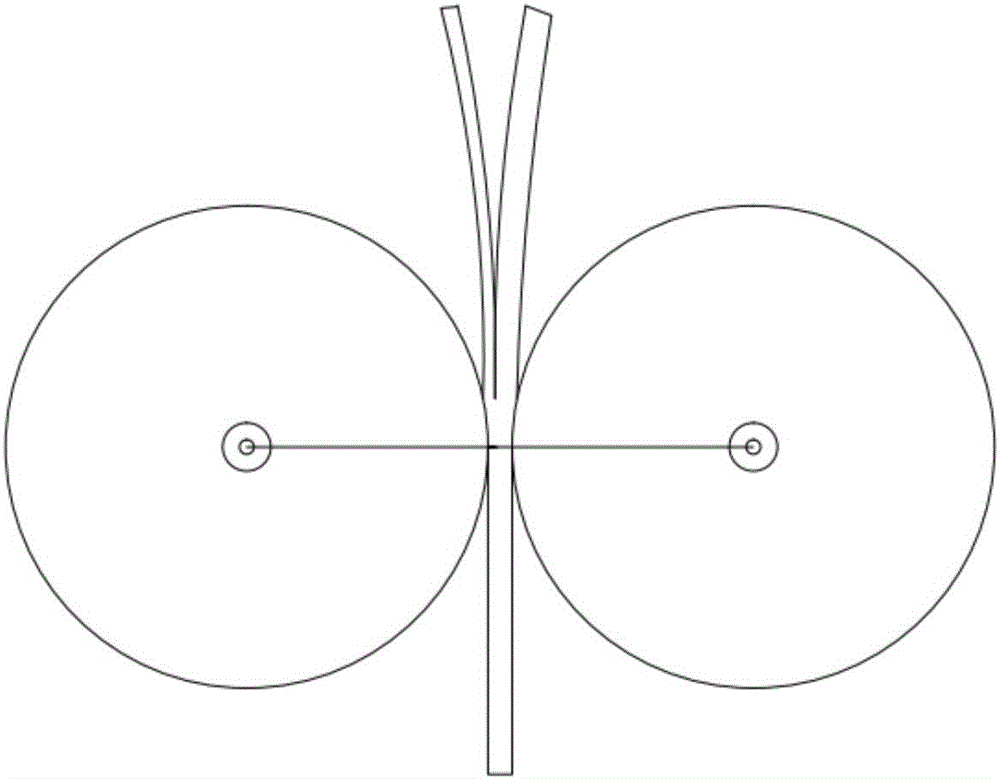

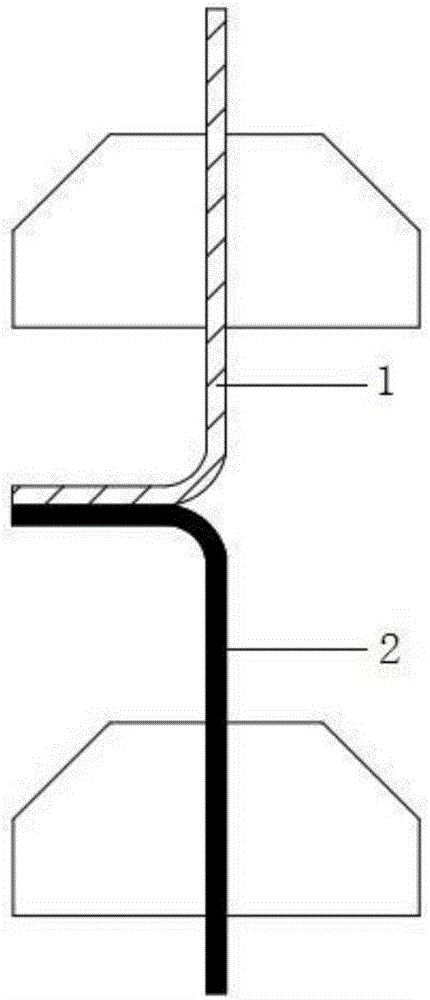

[0043] (1) Take a diaphragm sample and pole piece with a size of 100mm*300mm, and overlap them together and pass through a roller press at a slow speed, and hot press to obtain a sample. The rolling speed is 2mm / s, and the hot pressing temperature is 80°C. The hot pressing pressure is 1Mpa, and the diaphragm and the pole piece that have been rolled and bonded are cut out with a sample cutting machine, and the direction of the sample cutting is perpendicular to the direction of the coated diaphragm to obtain a test sample with a width of 12mm;

[0044] (2) Take a strip sample with a length of 200mm, gently peel off the diaphragm and one end of the pole piece by hand, and then fix the two ends of the stripped...

Embodiment 2

[0048] In this example, the adhesion between the PVDF coating film with a thickness of 16 μm and the pole piece is tested, the thickness of the base film is 14.5 μm, and a coating with a thickness of 1.5 μm is applied on one side. The specific operation steps are as follows:

[0049] (1) Take a diaphragm sample and pole piece with a size of 100mm*300mm, and overlap them together and pass through a roller press at a slow speed, and hot press to obtain a sample. The rolling speed is 5mm / s, and the hot pressing temperature is 90°C. The hot pressing pressure is 1.5Mpa, and the diaphragm and the pole piece bonded by roll are cut out with a sample cutting machine, and the direction of the cutting sample is perpendicular to the direction of the coated diaphragm to obtain a test sample with a width of 15mm;

[0050] (2) Take a strip sample with a length of 200mm, gently peel off the diaphragm and one end of the pole piece by hand, and then fix the two ends of the stripped sample in the...

Embodiment 3

[0054] In this example, the bonding force between the PVDF coating film with a thickness of 25 μm and the pole piece is tested, the thickness of the base film is 22 μm, and a coating with a thickness of 3 μm is applied on one side. The specific operation steps are as follows:

[0055] (1) Take a diaphragm sample and a pole piece with a size of 100mm*300mm, and overlap them together and pass through a roller press at a slow speed to obtain a sample by hot pressing. The rolling speed is 8mm / s, and the hot pressing temperature is 90°C. The hot pressing pressure is 1.8Mpa, and the diaphragm and the pole piece bonded by rolling are cut out with a sample cutting machine, and the direction of the sample cutting is perpendicular to the direction of the coated diaphragm to obtain a test sample with a width of 15mm;

[0056] (2) Take a strip sample with a length of 200mm, gently peel off the diaphragm and one end of the pole piece by hand, and then fix the two ends of the stripped sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com