Circular polaroid and organic light-emitting display device

A circular polarizer and polarizing technology, which is applied in the field of organic light-emitting display devices, can solve problems such as uneven life, characteristic changes, and UV tolerance effects, and achieve the effects of delaying time and degree, prolonging service life, and improving light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

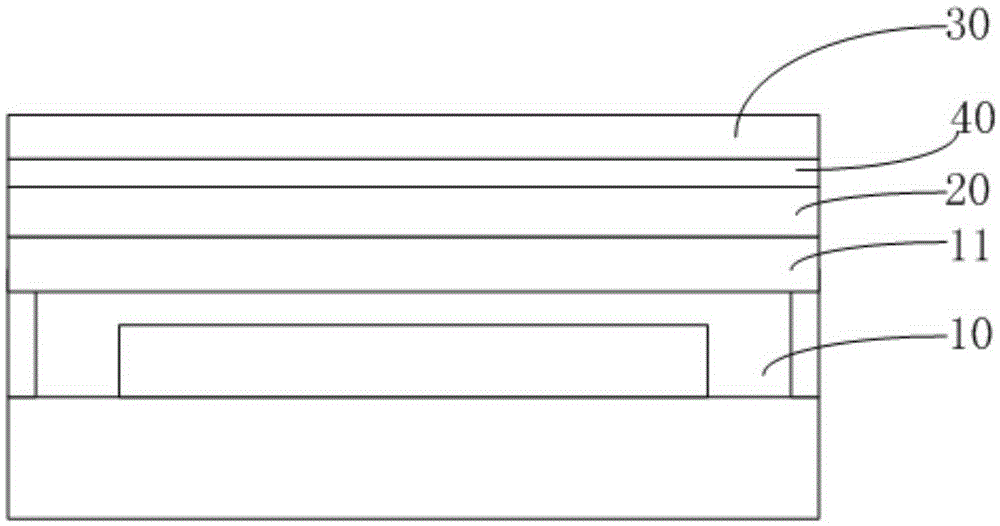

[0022] see figure 1 , is a schematic structural view of an organic light emitting display device according to Embodiment 1 of the present invention, the organic light emitting display device includes an organic light emitting diode device 10, a circular polarizer 20 bonded on the light emitting surface of the organic light emitting diode device 10, and a The touch panel 30 on the polarizer 20 ; wherein, the circular polarizer 20 and the touch panel 30 are bonded through the OCR layer 40 .

[0023] In this embodiment, the circular polarizer 20 is pasted on the light emitting surface of the package cover plate 11 of the organic light emitting device 10 .

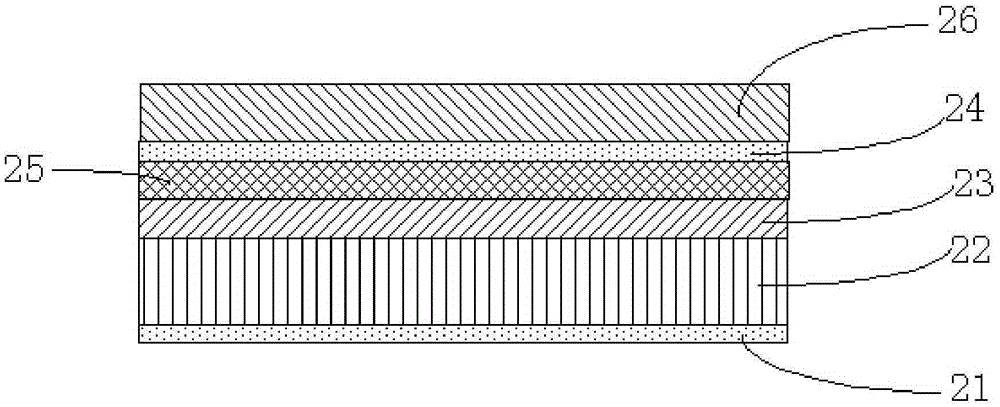

[0024] see figure 2 , is a structural schematic diagram of a circular polarizer 20, which includes a release film layer 21 bonded to the package cover plate 11, and a retardation film layer 22 and a polarizing function film layer 23 stacked on the release film layer 21 in sequence , and the quantum dot film layer 24 stacked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com