Super-hard blue light prevention display panel

A display panel, transparent display panel technology, applied in optics, filters, optical components, etc., can solve the problems of decreased light transmittance, low hardness, film scratches, etc., to achieve improved hardness, ultra-high hardness, good adhesion focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

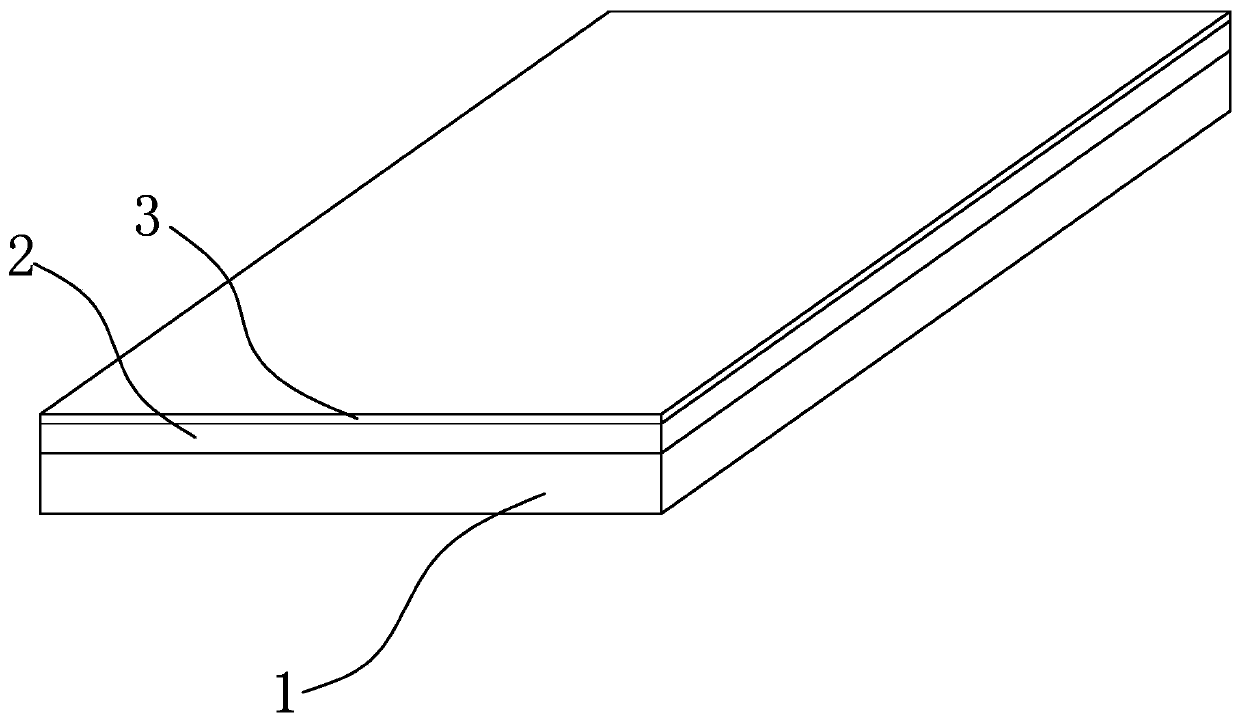

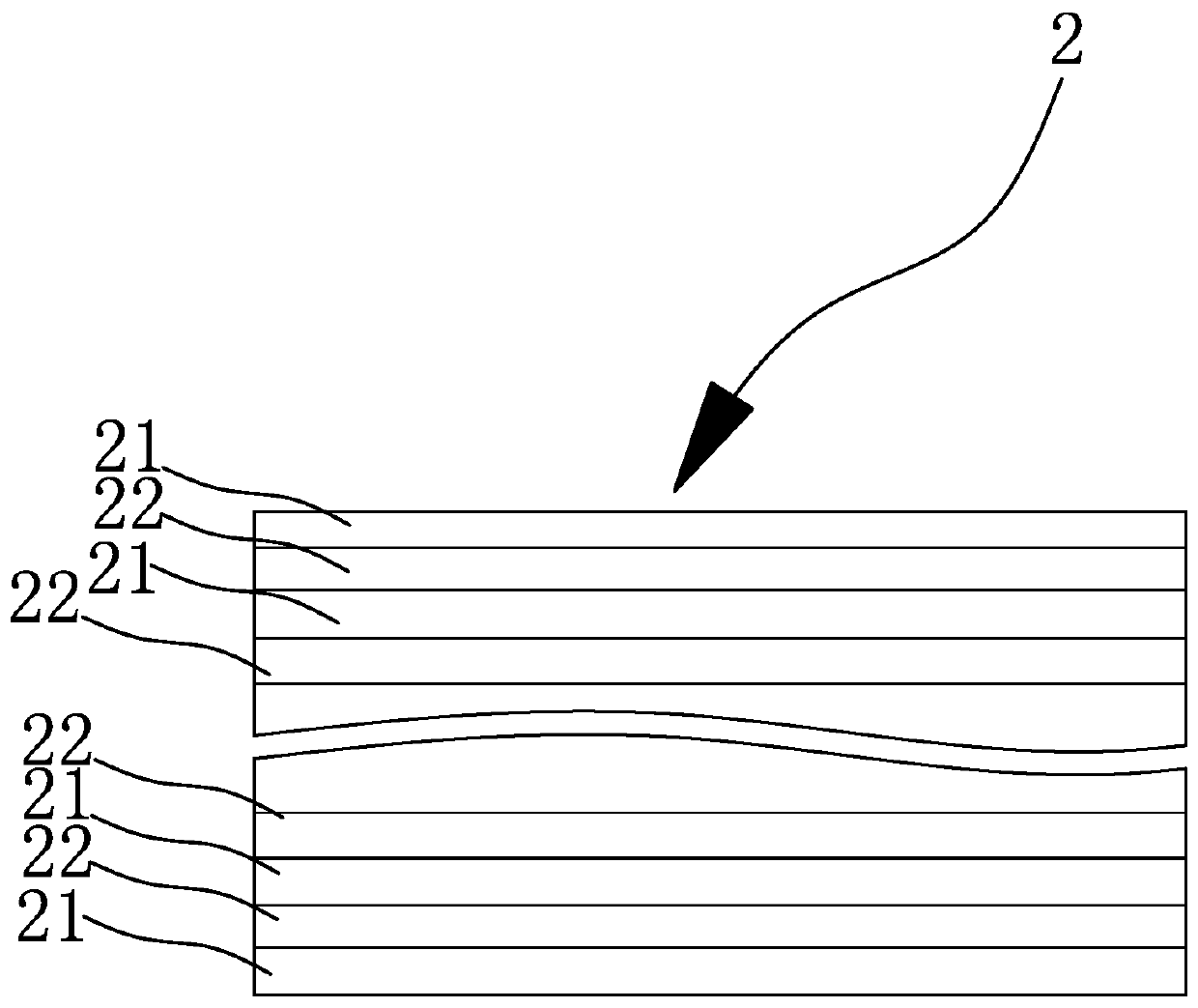

[0020] combine figure 1 with figure 2 As shown, the ultra-hard anti-blue light display panel includes a transparent display substrate 1, and more importantly, the surface of the transparent display substrate 1 is coated with an anti-blue light AR film 2, and the AR film 2 is made of Ti 3 o 5 Coating 21 with Al 2 o 3 Doped SiO 2 The coating layer 22 is formed by alternately repeating and orderly stacking and plating several times, which is equivalent to Ti 3 o 5 Coating 21 with Al 2 o 3 Doped SiO 2 The plating layers 22 are alternately overlapped, and Ti can be used by evaporation 3 o 5 The material is plated into Ti 3 o 5 Coating 21, using Al 2 o 3 Doped SiO 2 Al 2 o 3 Doped SiO 2 Coating layer 22; Here, when film coating, the coating layer that makes AR film 2 contact with transparent display substrate 1 is Ti 3 o 5 Coating 21, Al 2 o 3 Doped SiO 2 Middle Al 2 o 3 The doping amount is 1.0wt%-15wt%. By using the above two coating materials for altern...

Embodiment 2

[0024] In this implementation, specifically, Corning glass is used as the transparent display panel 1 , and the AR film 2 is coated on the surface thereof by vapor deposition, and the AF film 3 is coated on the surface of the AR film 2 . Further, the AR film 2 here is Ti with a thickness of 23.7nm from the inside to the outside. 3 o 5 Coating 21, Al with a thickness of 52.54nm 2 o 3 Doped SiO 2 Coating 22, Ti with a thickness of 39.81nm 3 o 5 Coating 21, Al with a thickness of 54.26nm 2 o 3 Doped SiO 2 Coating 22, Ti with a thickness of 35.67nm 3 o 5 Coating 21, Al with a thickness of 66.62nm 2 o 3 Doped SiO 2 Coating 22, Ti with a thickness of 34.34nm 3 o 5 Coating 21, Al with a thickness of 51.05nm 2 o 3 Doped SiO 2 Coating 22, Ti with a thickness of 42.12nm 3 o 5 Coating 21, Al with a thickness of 77.46nm 2 o 3 Doped SiO 2 Coating 22 and Ti with a thickness of 11.72nm 3 o 5 The coating composition of the coating layer 21, the thickness of the AF film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com