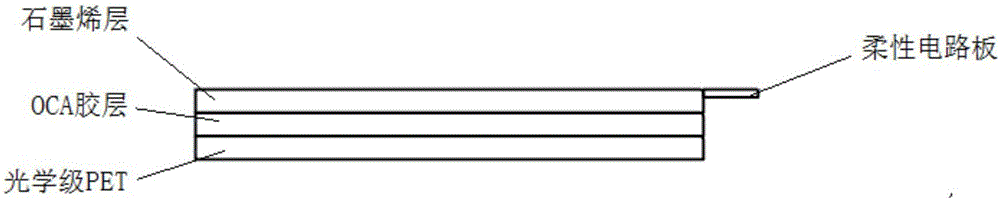

Manufacture method of OCA (optics clarity adhesive) substrate graphene touch screen

A production method and graphene technology, applied in chemical instruments and methods, lamination auxiliary operations, data processing input/output process, etc., can solve the problems of complex production process and thick touch screen, so as to avoid softening and save process , Improve the effect of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of manufacture method of OCA substrate graphene touch screen, comprises the steps:

[0027] 1) Graphene is grown on both sides of the growth substrate. The thickness of the growth substrate in this embodiment is 1 um, and the growth substrate is made of transition metal, and the transition metal in this embodiment is copper.

[0028] 2) Tear off the light release film of the OCA adhesive layer, and evenly bond it with the graphene layer with the growth substrate, remove the original growth substrate, and transfer the graphene layer to the touch screen carrier On the OCA adhesive layer, a graphene carrier film is obtained; the method for separating the growth substrate and the graphene layer adopts chemical etching, electrochemical method or mechanical stripping method, and the method for separating the growth substrate and the graphene layer of the present embodiment using chemical etching.

[0029] 3) screen printing silver paste on the graphene layer of graph...

Embodiment 2

[0034] A kind of manufacture method of OCA substrate graphene touch screen, comprises the steps:

[0035] 1) Graphene is grown on both sides of the growth substrate. The thickness of the growth substrate in this embodiment is 100 um, and the growth substrate is made of transition metal, and the transition metal in this embodiment is nickel.

[0036] 2) Tear off the light release film of the OCA adhesive layer, and evenly bond it with the graphene layer with the growth substrate, remove the original growth substrate, and transfer the graphene layer to the touch screen carrier On the OCA adhesive layer, a graphene carrier film is obtained; the method for separating the growth substrate and the graphene layer adopts chemical etching, electrochemical method or mechanical stripping method, and the method for separating the growth substrate and the graphene layer of the present embodiment By electrochemical method.

[0037] 3) screen printing silver paste on the graphene layer of ...

Embodiment 3

[0042] A kind of manufacture method of OCA substrate graphene touch screen, comprises the steps:

[0043] 1) Graphene is grown on both sides of the growth substrate. The thickness of the growth substrate in this embodiment is 1mm, and the growth substrate is made of transition metal, and the transition metal in this embodiment is copper.

[0044] 2) Tear off the light release film of the OCA adhesive layer, and evenly bond it with the graphene layer with the growth substrate, remove the original growth substrate, and transfer the graphene layer to the touch screen carrier On the OCA adhesive layer, a graphene carrier film is obtained; the method for separating the growth substrate and the graphene layer adopts chemical etching, electrochemical method or mechanical stripping method, and the method for separating the growth substrate and the graphene layer of the present embodiment adopts Mechanical peeling method.

[0045] 3) screen printing silver paste on the graphene layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com