Optimization method of oil leakage characteristics of aircraft fuel tank based on smooth particle hydrodynamics

A fluid dynamics, aircraft fuel tank technology, applied in the direction of constraint-based CAD, special data processing applications, geometric CAD, etc., can solve the problems of redundant oil spill performance, reduce oil body fluctuation suppression, large calculation consumption, etc. Flight control performance, faster response, and less computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with accompanying drawing and embodiment, and embodiment adopts the rectangular parallelepiped fuel tank that dividing plate is evenly arranged.

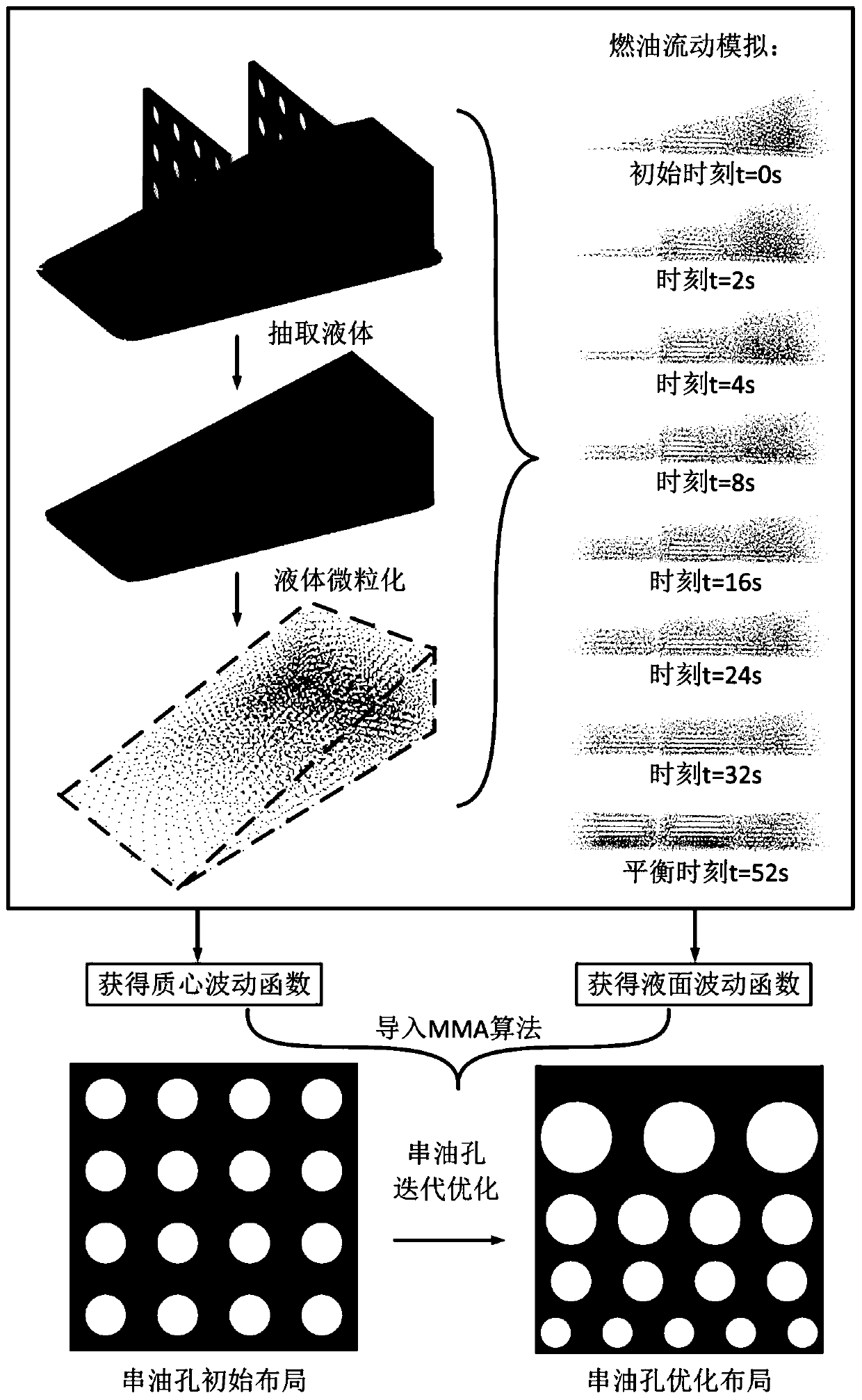

[0065] The method for optimizing the characteristics of oil leakage in aircraft fuel tanks based on smooth particle hydrodynamics includes the following steps:

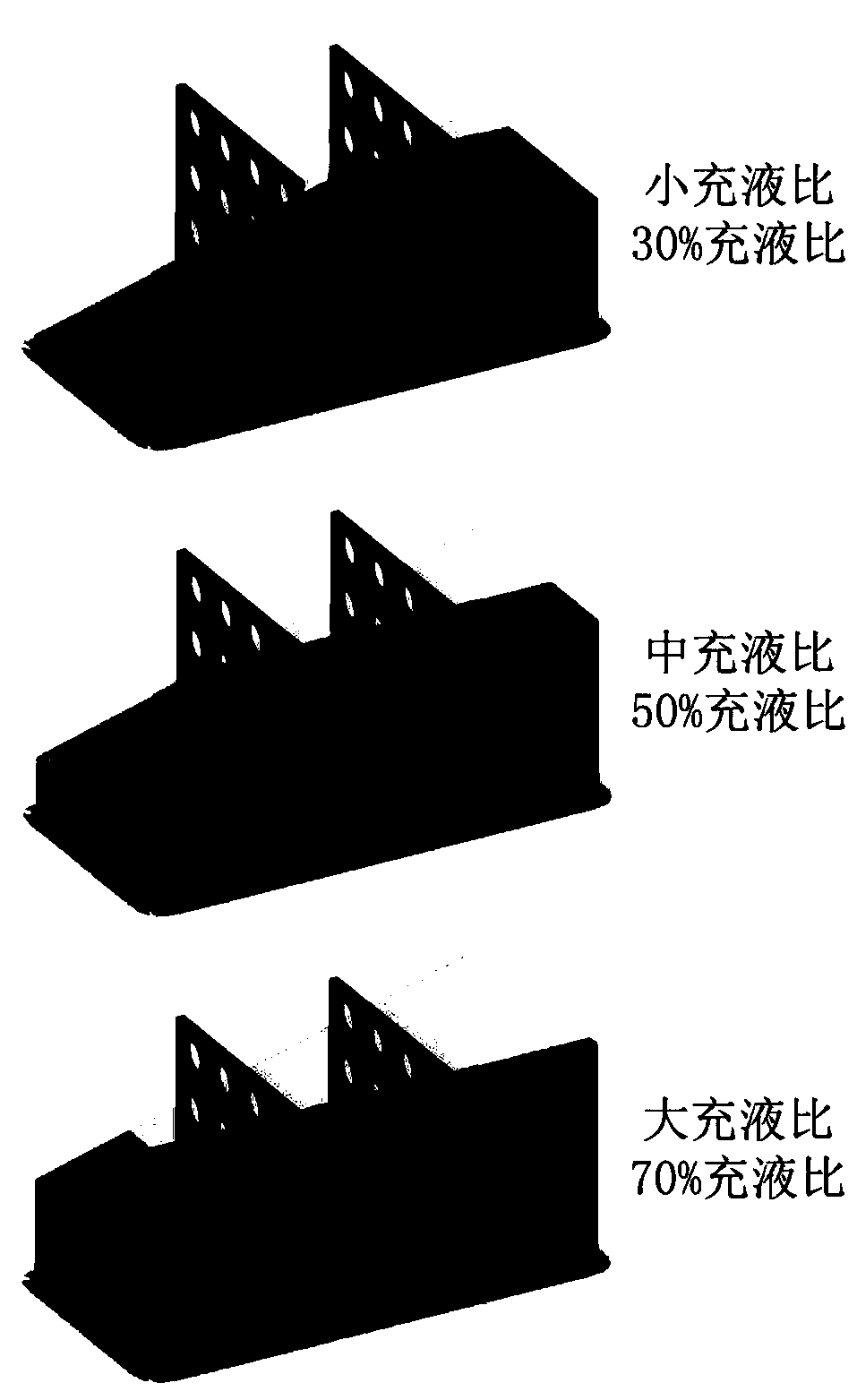

[0066] 1) Small liquid filling ratio fuel tank partition design:

[0067] Since the liquid level of the small liquid filling ratio tank is more likely to sway, the liquid level has a larger amplitude, and the time to calm down is longer, so this embodiment first takes the small liquid filling ratio as the priority design working condition, and defines 30% of the liquid filling ratio as the small In the working condition of the filling ratio, this embodiment studies the extreme working condition that the aircraft returns to the level flight state from a roll angle of 15 degrees. figure 1 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com