STT-MRAM storage unit

A technology of memory cells and seed layers, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as slowness, technical difficulties, and difficulty in adjusting the anisotropy constant K, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

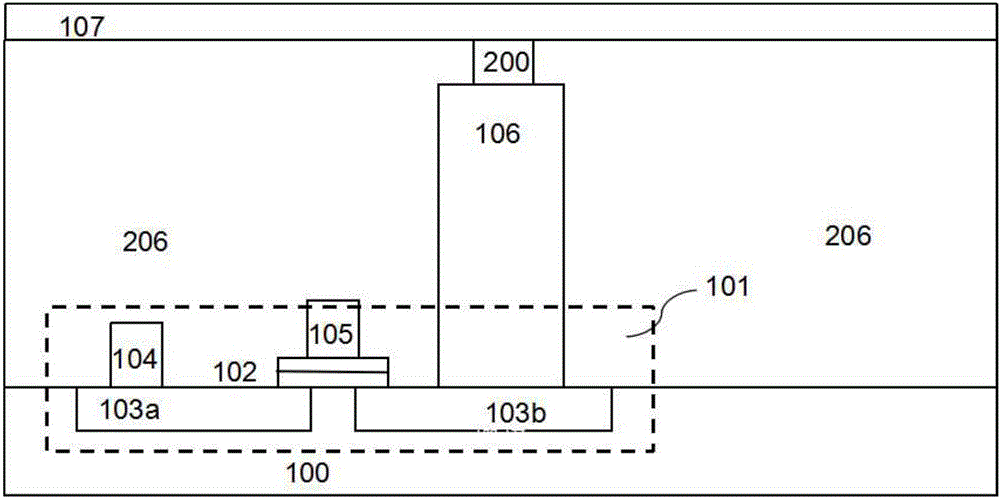

[0041] figure 1 It is the structure diagram of STT-MRAM storage unit. Contains a transistor 101 and MTJ unit 200 . Transistor 101 is built on substrate 100 and includes source 103 a , drain 103 b and gate stack 102 . The gate stack 102 is connected to the word line 105 , the drain 103 b is in drain contact with the MTJ unit 200 through the metal line 106 , and the source 103 a is in source contact with the source node region 104 . MTJ cell 200 is connected to word line 107 . The MTJ unit 200 is formed by adding a tunnel layer between the pinned layer and the free layer, and is perpendicular to the upper plane of the metal line 106 .

[0042] Various technical descriptions related to this show that the preparation of MTJ units can be achieved by conformal deposition techniques, such as atomic layer deposition (ALD) to prepare MTJ unit structures. Figure 1-2 The detailed structure of the invention related to the magnetic recording element is disclosed. The first part of th...

Embodiment 2

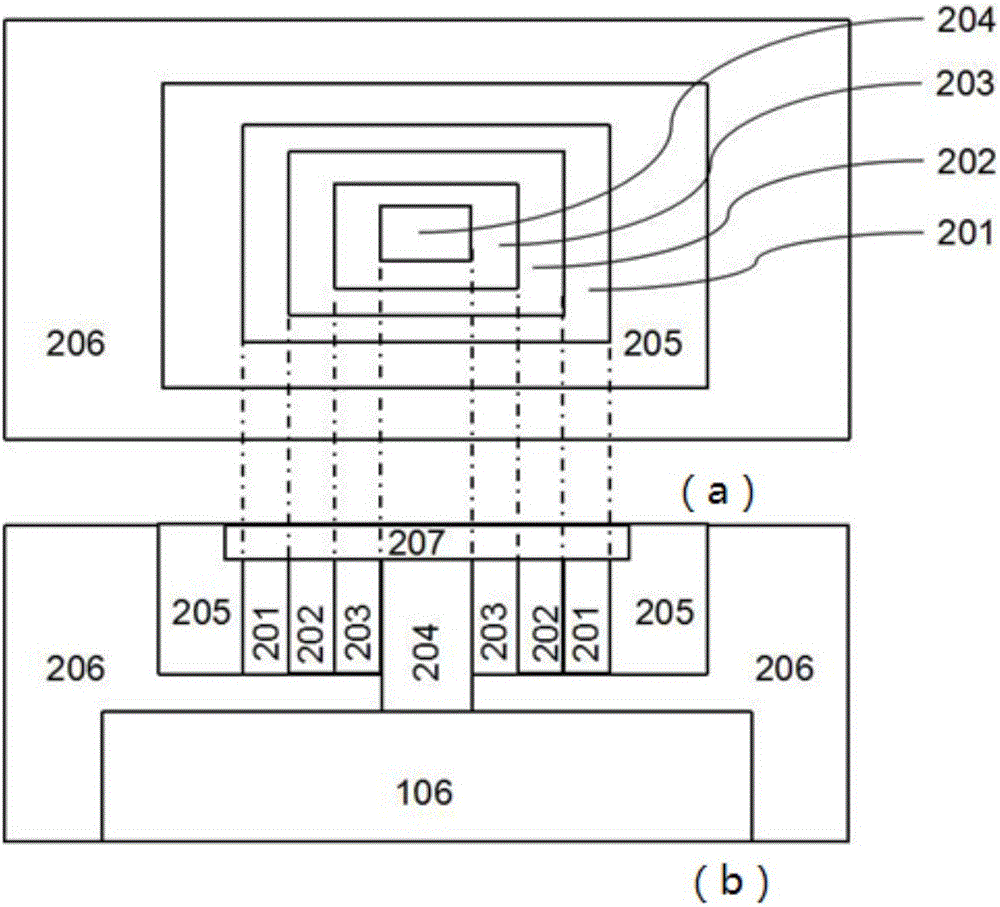

[0047] Figure 14 It is another three-dimensional STT-MRAM memory cell structure diagram. Contains a transistor 101 and MTJ unit 200 . The transistor structure is the same as that of Embodiment 1. Partial adjustments are made at the MTJ unit 200: the corresponding structure of the MTJ is changed from inside to outside into internal electrodes, free layers, barrier layers, pinning layers and external electrodes. The materials used in each layer structure and the preparation method are similar to those in Example 1. The specific structure of its MTJ is as follows Figure 15 shown.

[0048] Two preparation methods of the inner electrode 204 of the MTJ200.

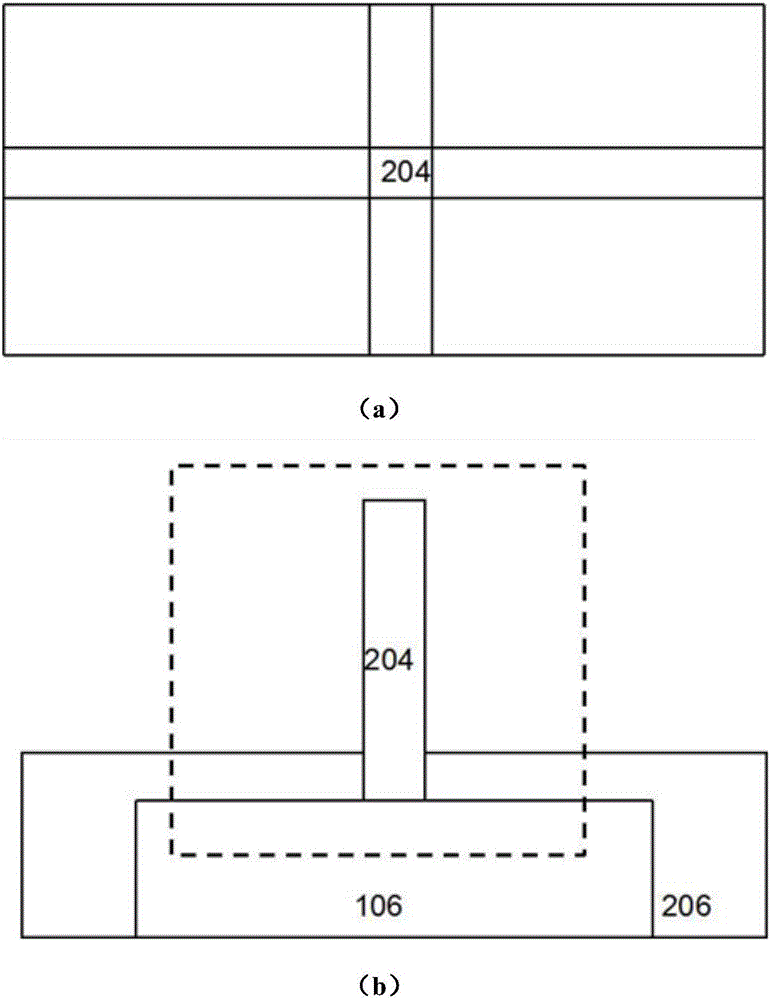

[0049] The first preparation method uses ion beam etching or electron beam etching to directly prepare the internal electrode 204 on 106, such as Figure 16 , 17 shown. Re-utilization of magnetron sputtering or atomic layer deposition (ALD) in Figure 17 Prepare a layer of insulating medium 206 on the basis of Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com