Automatic assembly support of lithium ion battery cell

A lithium-ion battery, automatic assembly technology, applied to battery components, batteries, circuits, etc., can solve the problems of increasing battery absorption of water, affecting electrochemical performance, reducing battery production efficiency, etc., to reduce manual participation and improve The effect of electrochemical performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

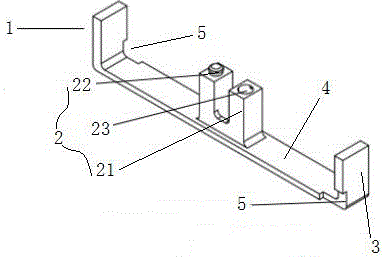

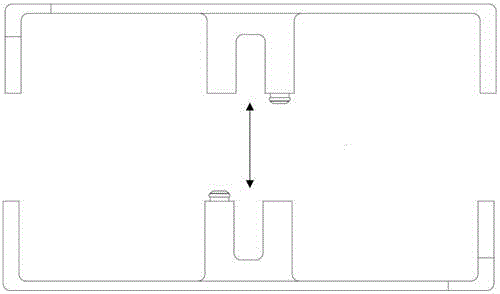

[0016] An automatic assembly bracket for lithium-ion battery cells, including a left frame 1, a middle frame 2, a right frame 3, and a horizontal frame 4. The bracket is an "E"-shaped structure as a whole, and the left frame 1, right frame 3, and horizontal frame 4 are integrally formed , the middle frame is fixedly connected by bolts, the middle frame 2 includes two sub-frames 21 arranged in parallel; the top of one of the sub-frames 21 is fixedly connected with the protrusion 22 by bolts, and the top of the other sub-frame 21 is provided with a groove 23, The protrusion 22 is matched with the groove 23; the staggered corners of the left frame 1 and the right frame 3 are provided with gaps 5 for electrolyte injection. During battery assembly and production, mechanical equipment can be used to snap together two "E"-shaped brackets through protrusions and grooves to form a "day"-shaped combined bracket; the tabs are placed in the two openings of the combined bracket during assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com