Assembling method for high-radiating lithium ion battery module

A lithium-ion battery, high heat dissipation technology, used in battery pack components, secondary batteries, non-aqueous electrolyte batteries, etc. problem, to achieve the effect of light weight, improved thermal conductivity, and fast cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention relates to a method for assembling a lithium-ion battery module with high heat dissipation. The invention realizes the water cooling of the lithium-ion cylindrical battery module through the hollow annular water tank. Compared with the air-cooled method, it has the advantages of fast cooling speed, uniform temperature, good effect, and convenience. The heat dissipation effect of the ion cylindrical battery module, and the characteristics of light weight and high strength, improve the heat dissipation performance and safety performance of the lithium-ion battery module.

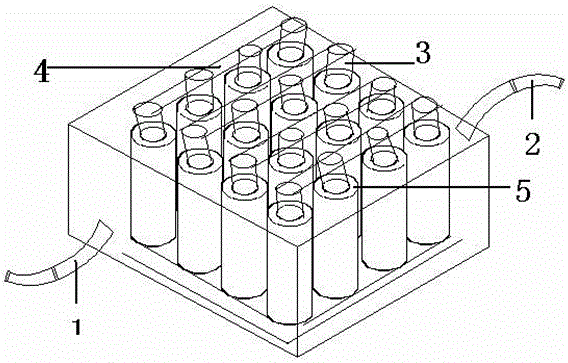

[0024] combine Figure 1-3 , the present invention uses water inlet pipe 1, water outlet pipe 2, lithium ion cylindrical battery 3, connecting piece 4, conductive glue and hollow annular water tank 5, lithium ion cylindrical battery 3 commonly used 18650 cylindrical battery, also can be other types of cylindrical battery.

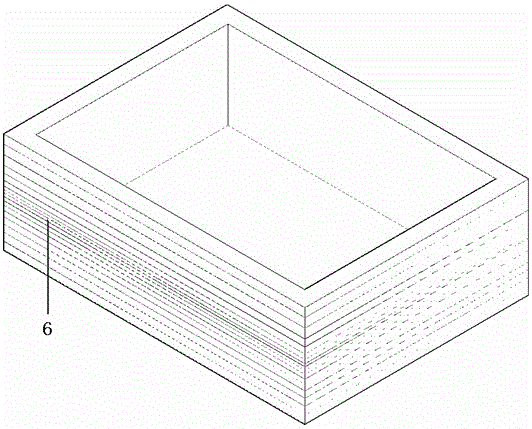

[0025] The hollow annular water tank is square or rectangular and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com