Method for manufacturing antenna on glass back cover and glass back cover equipped with antenna

A glass and antenna technology, applied in the field of electronic equipment, can solve the problem that the size and accuracy of the antenna needs to be improved, and achieve the effects of rich and changeable shapes, high production efficiency, and better communication effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a planar 2D glass back cover with an antenna, which is manufactured by the following steps.

[0033] S1. Spray a conductive paste layer on the protective ink layer of the glass back cover.

[0034] The conductive paste layer is produced by spraying photosensitive silver paste on the protective ink layer of the flat 2D glass back cover. The photosensitive silver paste includes 70wt% of silver powder and 30wt% of binder, and its viscosity is 1000-1500cps.

[0035] The entire spraying operation is carried out at a temperature of 40° C. and a pressure of 0.1 MPa. The surface on which the antenna will be installed is sprayed on the front, and the number of sprays is 1 to 3 times until a uniform and flat conductive paste layer is obtained.

[0036] After the spraying of the conductive paste layer is completed, the conductive paste layer is baked at 120° C. for 30 minutes. Until the shape of the conductive paste layer is basically fixed.

[0037] S2....

Embodiment 2

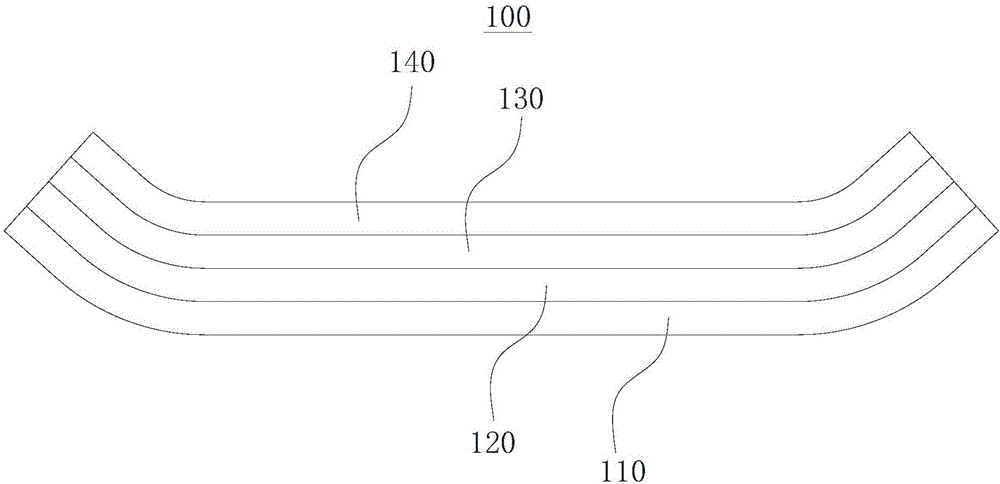

[0042] This embodiment provides a curved 2.5D glass back cover with an antenna, which is manufactured by the following steps.

[0043] S1. Spray a conductive paste layer on the protective ink layer of the glass back cover.

[0044] The conductive paste layer is produced by spraying photosensitive silver paste on the protective ink layer of the curved 2.5D glass back cover. The photosensitive silver paste includes 85wt% of silver powder and 15wt% of binder, and its viscosity is 500-1000cps.

[0045] The entire spraying operation is carried out at a temperature of 40° C. and a pressure of 0.3 MPa. The surface on which the antenna will be installed is sprayed on the front, and the number of sprays is 1 to 3 times until a uniform and flat conductive paste layer is obtained.

[0046] After the spraying of the conductive paste layer is completed, the conductive paste layer is baked at 150° C. for 10 minutes. Until the shape of the conductive paste layer is basically fixed.

[00...

Embodiment 3

[0052] This embodiment provides a four-sided curved 3D glass back cover with an antenna, which is manufactured by the following steps.

[0053] S1. Spray a conductive paste layer on the protective ink layer of the glass back cover.

[0054] The conductive paste layer is produced by spraying photosensitive silver paste on the protective ink layer of the four-sided curved 3D glass back cover. The photosensitive silver paste includes 50wt% of silver powder and 50wt% of binder, and its viscosity is 2500-3000cps.

[0055] The entire spraying operation is carried out at a temperature of 40° C. and a pressure of 0.8 MPa. The surface on which the antenna will be installed is sprayed on the front, and the number of sprays is 1 to 3 times until a uniform and flat conductive paste layer is obtained.

[0056] After the spraying of the conductive paste layer is completed, the conductive paste layer is baked at 100° C. for 30 minutes. Until the shape of the conductive paste layer is basi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Depth of stress layer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com