Conductive material for connecting parts with excellent micro-sliding wear resistance

A technology for conductive materials and connecting parts, applied in the field of conductive materials for connecting parts, can solve problems such as increased insertion force, and achieve improved micro-sliding wear resistance, excellent micro-sliding wear resistance, and less reduction in contact pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

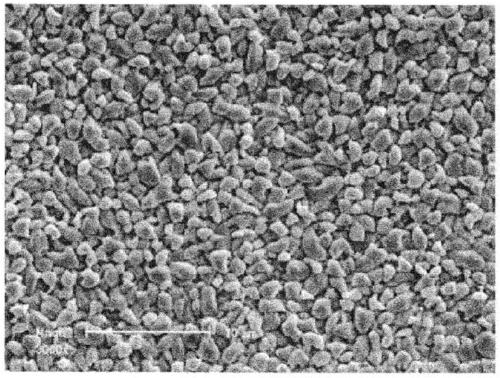

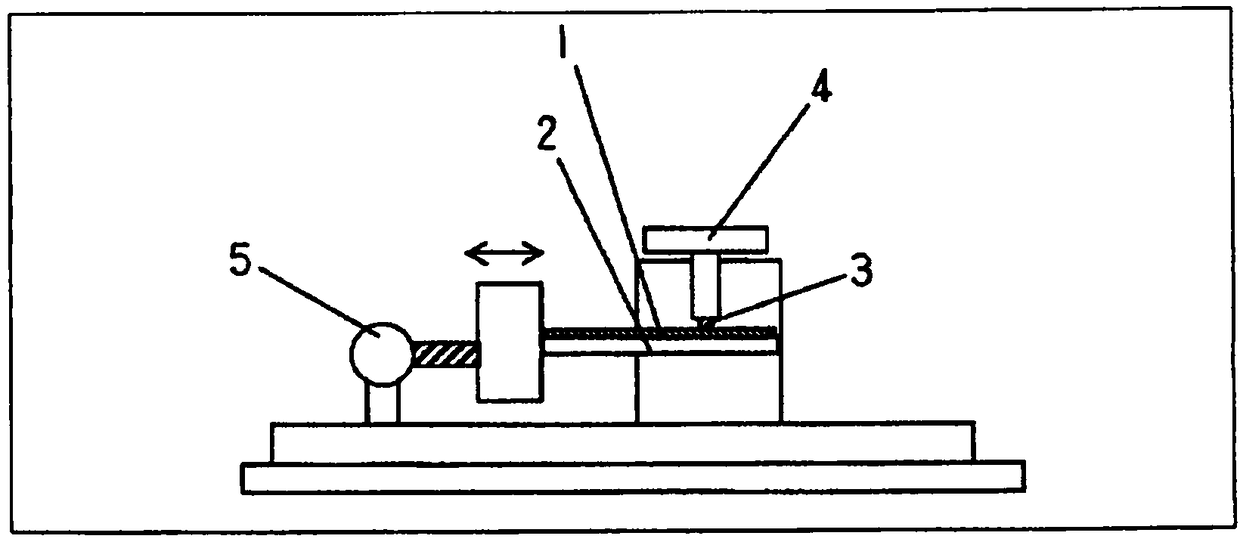

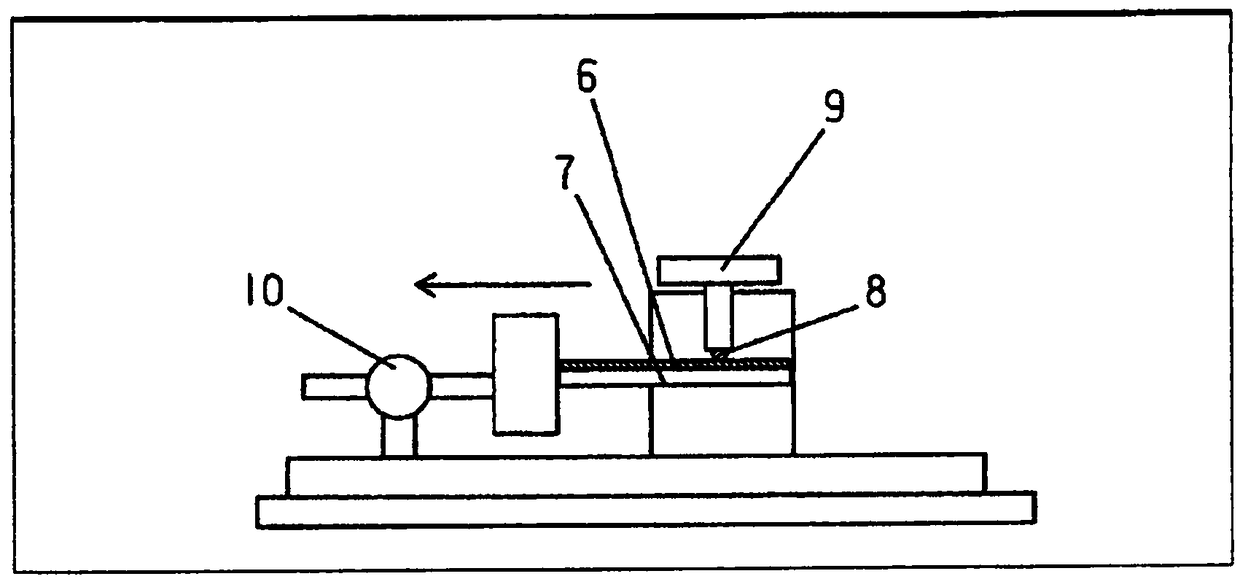

Image

Examples

Embodiment approach A

[0044] Hereinafter, an embodiment corresponding to claim 1 of the present invention will be described.

[0045] [Copper alloy base material]

[0046] (1) Characteristics of copper alloy

[0047] The stress relaxation rate of Cu-Ni-Si alloys widely used in fitting-type terminals is 12 to 20% when the bending stress of 80% of the yield strength of 0.2% is loaded and kept for 1000 hours at a holding temperature of 150°C. . However, the stress relaxation rate increases as the holding temperature increases, and becomes 15 to 25% at 160°C, 25 to 30% at 180°C, and 30 to 40% at 200°C. In the case of a female terminal with strict requirements on the stress relaxation rate, as described above, the stress relaxation rate after holding for 1000 hours at the assumed use temperature is often required to be 25% or less as the design criterion. Therefore, when the assumed operating temperature exceeds, for example, 160° C., it is difficult to use a Cu—Ni—Si alloy as a raw material of the f...

Embodiment approach B

[0121] Hereinafter, an embodiment corresponding to claim 3 of the present invention will be described.

[0122] [Copper alloy base material]

[0123] (1) Composition of Cu-Fe-P alloy

[0124] The copper alloy strip according to the present embodiment is a Cu—Fe—P alloy containing Fe: 0.01 to 2.6% by mass, P: 0.01 to 0.3% by mass, and the remainder is Cu and unavoidable impurities.

[0125] Fe is a main element that precipitates in the form of Fe simple substance or Fe-based intermetallic compound and improves the strength and heat resistance of the copper alloy. When the content of Fe is less than 0.01% by mass, the amount of precipitates formed is small, and although the improvement of the electrical conductivity is satisfied, the contribution to the improvement of the strength is insufficient, and the strength is insufficient. On the other hand, if the content of Fe exceeds 2.6% by mass, the electrical conductivity tends to decrease, and if an attempt is made to increase t...

Embodiment approach C

[0143] Hereinafter, an embodiment corresponding to claim 5 of the present invention will be described.

[0144] [Copper alloy base material]

[0145] (1) Composition of Cu-Zn alloy

[0146] The Cu—Zn alloy strip according to the present embodiment contains 10 to 40% by mass of Zn, and the balance is composed of Cu and unavoidable impurities. This Cu—Zn alloy is called red copper and brass, and includes C2200, C2300, C2400, C2600, C2700, and C2801 specified in JIS H 3100.

[0147] If the content of Zn is less than 10% by mass, the strength required as a fitting terminal will be insufficient. On the other hand, when the content of Zn exceeds 40% by mass, bending workability is deteriorated due to a decrease in elongation. Therefore, the content of Zn is set to 10 to 40% by mass. The lower limit of the Zn content is preferably 12 mass%, more preferably 15 mass%, and the upper limit is preferably 38 mass%, more preferably 35 mass%.

[0148] In order to improve the strength, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com